1.I-Advantages kunye nokungonakali kwe-laser welding machine kunye nobubanzi besicelo sayo

Umatshini wokuwelda iLaser luhlobo olutsha lwendlela yokuwelda, enamandla ebhondi ephantsi, indawo echaphazeleke bubushushu ebanzi kunye nezinye iingenelo ezininzi, kwimarike yangoku yesinyithi, i-laser welding isetyenziswa kakhulu, kudala isetyenziswa kuzo zonke iinkalo zobomi. , ezifana: indebe yokugquma isinyithi, imboni yeselula, ishishini lezonyango, ishishini leemoto kunye namanye amacandelo amaninzi oshishino.

01 Izinto eziluncedo kumatshini welding laser

Xa kuthelekiswa netekhnoloji yewelding yemveli, itekhnoloji ye-laser ye-welding ayiyonxibelelwano yokunxibelelana, inkqubo yokusebenza ayifuni uxinzelelo, inesantya esikhawulezayo sokuwelda, amandla aphezulu, ubunzulu, i-deformation encinci, i-weld seam emxinwa, indawo encinci echaphazeleke bubushushu, kunye nendawo yokusebenza. i-deformation incinci, ukulandelwa komsebenzi wokucutshungulwa kuncinci, ukunciphisa imveliso ye-manual, ukuguquguquka okuphezulu, ukhuseleko oluninzi kunye nezinye izibonelelo.

Itekhnoloji yokuwelda iLaser inokusetyenziselwa ukuwelda izixhobo ezilahlayo ezifana nentsimbi ephezulu yokunyibilika, kunye nezixhobo ezingezizo ezentsimbi ezifana neekeramics kunye neglasi yendalo, eneziphumo ezilungileyo zokuwelda kwizinto ezimile kunye nokuguquguquka okukhulu.Ukuwelda iindawo ezingafikelelekiyo, ukuhanjiswa kwe-flexible non-contact welding yenziwa.I-laser beam inokwahlulwa ngexesha kunye namandla, okwenza ukuba ukusetyenzwa kwangaxeshanye kwiiplanga ezininzi, ukubonelela ngeemeko ze-welding echanekileyo.

02 Amanqaku kufuneka aqatshelwe malunga nokusetyenziswa koomatshini be-laser welding

Le miba ilandelayo kufuneka iqatshelwe xa usebenzisa izixhobo ze-laser welding machine

(a) Indawo yenxalenye edityanisiweyo kufuneka ichaneke kakhulu, iqinisekise ukuba ingaphakathi kugxininiso lomqadi welaser.

(b) Xa inxalenye edityanisiweyo ifuna ukusetyenziswa kwento edibeneyo, kufuneka kuqinisekiswe ukuba indawo yokugqibela yendawo edibeneyo kufuneka ihambelane nendawo ye-weld apho umqa we-laser uya kuchaphazela.

(c) Ubukhulu bobukhulu obunokuwelda bulinganiselwe, ukungena kwezixhobo zokusebenza ezinobukhulu obungaphezulu kwe-19mm kumgca wemveliso kufuna uthethwano nomenzi ukuze abonelele ngenkxaso yobuchwephesha.

03 Ukusetyenziswa koomatshini bokuwelda ngelaser

1. Ishishini lebhetri

Iselfowuni kunye neemveliso ezininzi zekhowudi yebhetri zisetyenziswa ukuwelda ngelaser.

2. Ishishini lekhitshi lokuhlambela

Ukuchaneka kwe-laser welding inenkangeleko engcono, ngoko ke kwindawo yokuhlambela ephezulu yeemveliso zensimbi ezingenasici nge-laser yokumakisha i-laser welding inoluhlu olubanzi lwezicelo.Ezifana nezi: izibambo, iifaucets, iimela zokusika ezingenasici kunye neyona ndlela ininzi ngokumakishwa kwe-laser yokuveliswa kwe-LOGO yenkampani, iiketile zombane zomgangatho ophezulu kunye nezinye izitywina nazo zisebenzisa i-laser welding ukugqiba.I-Kitchenware, i-tableware group welding butt welding, ukuvula i-mold mold kunye nokulungiswa kunye nokutshintsha ukubumba kwinkqubo yokusetyenziswa.

3. Iimveliso zedijithali, iiselfowuni, ishishini lekhompyutha

Ukusetyenzwa kweLaser ngenxa yetekhnoloji yokulungiswa okuchanekileyo, kwidijithali, kwiselfowuni, kwikhompyuter izicelo ezidume ngakumbi njenge: iiselfowuni, iMP4, iqokobhe leMP3 ukuwelda iqokobhe lelaser, umgca wojongano, iikhompyuter zelaptop, izixhobo zefayibha optic indawo yokuwelda, ukuwelda kwesixhobo se-chassis sekhompyuter. .

4. Ishishini loomatshini bobunjineli

Izixhobo zokuhlanjululwa kwe-welding, i-electromechanical parts welding, i-connector ethwele ukulungiswa.

5. I-Electronics, imboni yombane

Ekubeni ukucutshungulwa kwe-laser kuyindlela yokungaqhagamshelwanga, ayivelisi i-extrusion ye-mechanical okanye i-mechanical stress, ngoko ihlangabezana ngokukodwa neemfuno zokuqhuba ishishini lombane.Ezinje: i-transformers, i-inductors, i-connectors, i-terminals, i-fiber optic connectors, i-sensor, i-transformers, i-switchers, i-cell phone battery, i-microelectronic components, i-elekthronikhi yesekethe edibeneyo kunye nezinye i-welding.

6. Ishishini lezacholo

Ekubeni ukusetyenzwa kwe-laser kulungile kakhulu, kukulungele kwiimveliso ezixabisekileyo kunye ezincinci kwishishini lezacholo.Njengoko umqadi ogxininise kwilaser ulunge kakhulu, uyandiswa ngemakroskopu ukukhulisa iindawo ezincinci zobucwebe kunye nokuqonda ukuwelda okuchanekileyo.I-laser spot welder sisixhobo esiyimfuneko sokudibanisa amatsheyina anqabileyo kunye nokufakwa kwamatye anqabileyo.

7. I-Hardware, izixhobo, imboni yezixhobo

Isixhobo, isivamvo, ikitchenware, i-tableware group welding butt welding, ukuvula i-mold mold kunye nokulungiswa kunye nokutshintsha ukubumba ngexesha lokusetyenziswa.I-welding engenamthungo ye-tableware yensimbi engenasici, i-welding ekudibaneni kondoqo wemitha.

8. Iimoto, ishishini lemoto yombane

Ukusetyenzwa kweLaser ekusetyenzweni okungadibanisiyo, akukho ngcoliseko kwimveliso, isantya esiphezulu, kufanelekile ngakumbi kwiimfuno zenkqubo yokuvelisa iimpahla zabathengi ezikwizinga eliphezulu, ezinje ngemoto yokudial welding, ivalve welding, piston ring welding, automotive cylinder gasket welding, umbhobho wokukhupha, i-welding filter, i-welding ye-automotive security generator yegesi.Ukusika iinxalenye zeLaser kuvavanyo kunye nenqanaba elincinci lokuvelisa iimoto, kunye ne-welding yeebhetri zezithuthi zombane.

9. Ishishini lezinto zokwakha zokukhanyisa amandla

Ukusetyenzwa kweLaser kusetyenziswa kakhulu kwimveliso ye-laser solar cell: njengokusika i-solar silicon wafer laser scribing, i-solar water heat heat conduction plate welding.Ukusetyenzwa kweLaser, njengendlela yokusingqongileyo kunye nokusebenza kakuhle, kuya kusetyenziswa ngokubanzi kwixesha elizayo.

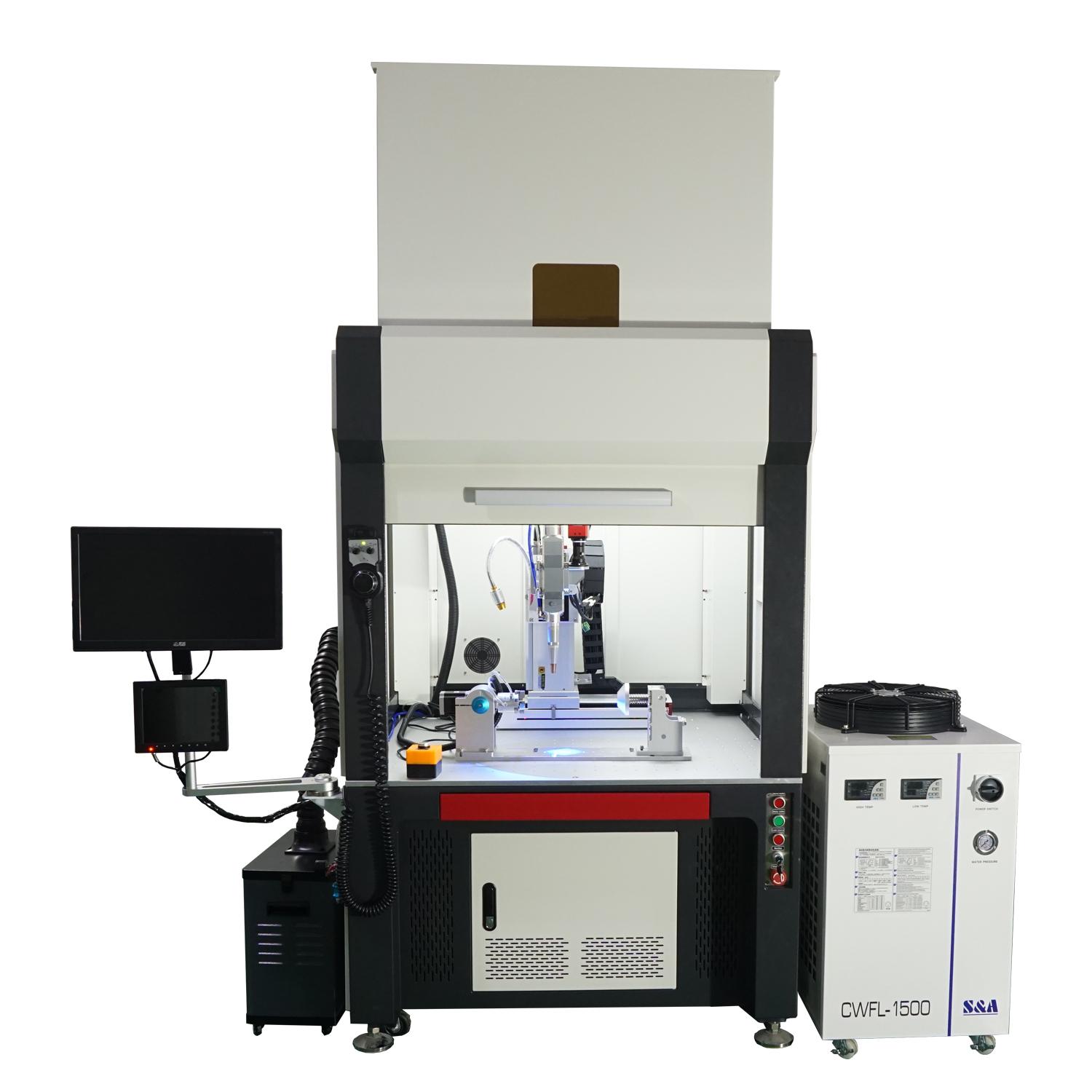

2.Yintoni umatshini wokuwelda we-laser we-Platform?

Platform umatshini laser welding oluzenzekelayo ngumatshini welding oluzenzekelayo esebenzisa i-high-energy laser pulses ukutshisa ekuhlaleni izinto kwindawo encinci.Amandla emitha yelaser asasazwa ngokuqhutywa kobushushu ukuya ngaphakathi kwesixhobo kwaye imathiriyeli iyanyibilika ukwenza ichibi elithile elinyibilikisiweyo.Isetyenziselwa ikakhulu ukuwelda izinto ezinodonga olubhityileyo kunye namacandelo achanekileyo, kwaye inokuqonda ukuwelda kombane, i-welding ye-butt, i-lap welding, i-welding ye-seal, njl. i-porosity, ulawulo oluchanekileyo, ukuchaneka kokuma okuphezulu, kunye nokuzenzekelayo ngokulula.

3.Yintoni umatshini wokuwelda welaser ophathwa ngesandla?

Njengoko igama lisitsho, umatshini we-laser welding manual luhlobo lwezixhobo zokuwelda ezifuna ukusebenza ngesandla.Esi sixhobo sokuwelda sinokwenza i-laser welding kwi-workpieces emide kunye nenkulu.Xa i-welding, indawo echaphazelekayo yokushisa incinci kwaye ayibangeli i-deformation, i-blackening kunye namanqaku ngasemva kwendawo yokusebenza.Ubunzulu be-welding bukhulu, i-welding iqinile, ukunyibilika kwanele, kwaye akukho xinzelelo kwi-melt pool apho iprojekti yezinto ezibunjiweyo zidibana ne-substrate.

4.Nguwuphi umahluko phakathi komatshini wokuwelda we-laser kunye nomatshini we-laser welding owenziwe ngesandla?

Oomatshini bokuwelda be-laser ngokuzenzekelayo badibanisa ngokuzenzekelayo ngokwenkqubo emiselweyo emva kokusekwa kwisoftware;oomatshini bokuwelda i-laser manual, eyaziwa ngokuba yi-spot welding, isetyenziswa ngabasebenzisi xa besebenzisa izixhobo zokuwelda nge-laser ngokukhulisa okuphezulu kwiscreen.

I-Visual spot welding yenziwa ngesandla kwaye ngokuqhelekileyo yenziwa ngabavelisi bezixhobo ze-laser ukuhlangabezana neemfuno zomsebenzisi.Bambalwa abavelisi abanezinto zesitokhwe.Ukuba izinto zesitokhwe ziyafumaneka, zinikezelwa kumsebenzisi njengeprototype okanye ireferensi yokuqinisekisa.Okubaluleke ngakumbi, amandla kunye neempawu zezixhobo ze-welding zichongwa ngokubonisana nomsebenzisi, kwaye kufuneka sinikezele nomsebenzisi ngemveliso yezixhobo ezingabizi kakhulu ngokusekelwe kwiindleko zokuthenga.Kukweyiphi na imeko kungcono ukusebenzisa umatshini we-laser welding manual, xa kuthelekiswa nomatshini wokuwelda we-laser, kungekhona nje iindleko zokuthenga eziphezulu, kodwa iindleko zokuzigcina ziphezulu kakhulu.Eyona nto ichaneke ngakumbi yeyona nto ibaluleke kakhulu ekugcinweni kwayo kwaye ngokwendalo ixabisa kakhulu.Ukongeza, i-laser ye-laser ye-welding ezenzekelayo igxininisa ngokukodwa kwi-automation ye-CNC yeqonga lomsebenzi, elifuna ukusebenza okuphezulu kunye nokuguquguquka kweqonga lomsebenzi, kodwa ekusebenzeni, oku akusiyo i-panacea, kwaye ezininzi zokutshintsha iimveliso ezahlukeneyo azikwazi ukusetyenziswa. imida indima umatshini welding laser oluzenzekelayo.Namhlanje, sigxininisa kumatshini we-laser welding manual, ngoko ke isixhobo semanuwali sisombulula ngokwendalo ezi ngxaki zingasentla.Umsebenzi wayo welding kukwenza umsebenzi welding nge-handheld laser welding joint with various angles control angles, ngoko ke kunokuthiwa isixhobo laser non-custom ukuziqhelanisa ukuwelda iimilo ezininzi neeengile imveliso.Ngethuba nje amandla aphezulu ngokwaneleyo, anokuziqhelanisa ne-welding yeemveliso ezininzi

Ukuveliswa koomatshini bokuwelda i-laser ngokuqinisekileyo kuphantsi kakhulu kunoko kwezixhobo ezizenzekelayo ngokupheleleyo.Nangona kunjalo, ukusetyenzwa kwe-decentralized okanye ukusetyenzwa kwe-non-scale-scale kunye ne-welding yezityalo zemveliso, ukuwelda kwe-laser manual kunenzuzo ngakumbi.Akukho mfuneko yokumisela itafile ye-welding kwaye ugweme ingxaki yendawo enkulu yomgangatho.Ukongeza, iindibano zocweyo ezincinci zidibanisa iintlobo ngeentlobo zeemveliso ezinemilo engaqhelekanga, ngoko ke i-laser welding manual inokuhlangabezana ngokupheleleyo neemfuno zemveliso enjalo kwaye ikwazi ukuziqhelanisa kakuhle.

I-laser welding manual ngaphandle kwetafile ye-welding echanekileyo, ukusetyenziswa okuphantsi kwezinto ezisetyenziswayo kunye neendleko eziphantsi zokugcinwa kwezixhobo.Ngokubanzi, kufuneka sigcine iibhentshi zokusebenza ezininzi, ngelixa izixhobo ze-laser ze-manual zinokuwugqiba umsebenzi logama nje zixhotyiswe ngamajoyinti aphathwayo e-laser welding.Kulula ukubuyisela, ixabiso eliphantsi lamalungu okutshintshwa.Ukuba awuyazi indlela yokuyibuyisela endaweni yayo, unokubanika umenzi ukuba agcinwe ngokuthe ngqo ngaphandle kokukhathazeka ngokuthumela.

Umahluko phakathi koomatshini bokuwelda laser oluzenzekelayo kunye noomatshini bokuwelda i-laser manual kwabelwana apha.Abantu abaninzi banokucinga ukuba i-laser welder ezenzekelayo ingcono kuba izenzekelayo, kodwa inyaniso kukuba ezi ntlobo zimbini zezixhobo zisetyenziselwa iinjongo ezahlukeneyo kwaye nganye ineenzuzo zayo.Kwinkqubo yokhetho, kufuneka kwakhona sikhethe izixhobo zokuwelda i-laser ezifanelekileyo kwimveliso yethu ngokweemfuno zethu zokwenyani.

Ixesha lokuposa: Feb-01-2023