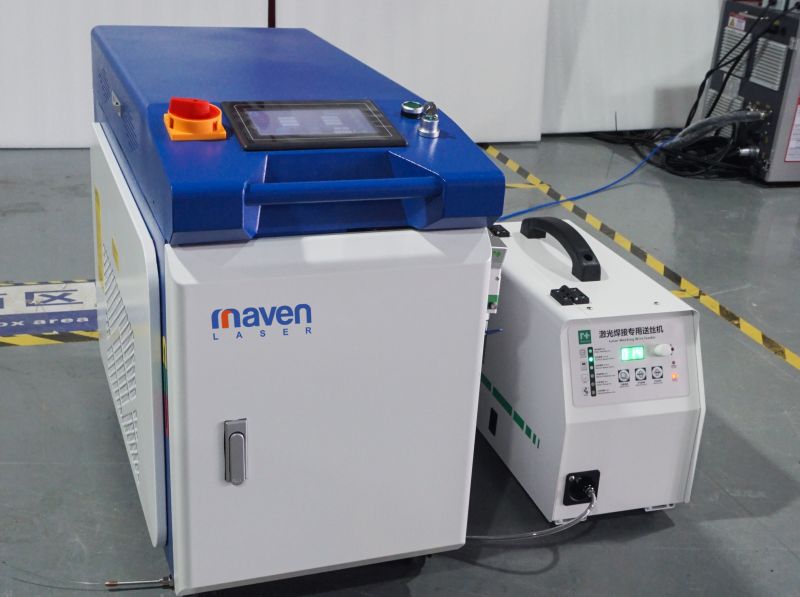

Ukuwelda kweLaser yindlela yokuwelda esebenzayo nechanekileyo esebenzisa umqadi welaser oxineneyo ngamandla njengomthombo wobushushu, kwaye yenye yezinto ezibalulekileyo ekusetyenzisweni kobuchwepheshe bokusetyenzwa kwe-laser. Nguwuphi umahluko phakathi kwe-laser welding kunye ne-welding eqhelekileyo? Yintoni ekufuneka ihlawulwe xa usenza i-laser welding? I-MAVEN ikuzisa uchungechunge lwe-welding laser welding ephathwayo.

Umatshini wokuwelda we-laser ophathwa ngesandla usetyenziswa ikakhulu kwintsimbi enkulu kunye nobungakanani obuphakathi, iikhabhathi, i-chassis, umnyango wealluminiyamu kunye neefreyimu zefestile, izitya zokuhlambela zensimbi engenasici kunye nezinye izinto ezinkulu zokusebenza ezifana nezikhundla ezizinzileyo ezinje ngeengile zasekunene zangaphakathi, ii-engile zangaphandle zasekunene, kunye iiwelds zenqwelomoya. Indawo echaphazelekayo yokushisa incinci ngexesha le-welding kunye ne-deformation encinci, kwaye ubunzulu be-welding bukhulu, kwaye i-welding iqinile. Isetyenziswa ngokubanzi kwishishini lekhitshi kunye negumbi lokuhlambela, ishishini lezixhobo zasekhaya, ishishini lentengiso, ishishini lokubumba, ishishini lemveliso yensimbi engenasici, ishishini lobunjineli bensimbi engenasici, ishishini lomnyango kunye nefestile, ishishini lezandla, ishishini lempahla yasekhaya, ishishini lefenitshala, ishishini lezixhobo zemoto, njl.

Ke, zeziphi izinto eziluncedo koomatshini bokuwelda belaser xa kuthelekiswa ne-arc welding njl.

1.Yonga iindleko zabasebenzi

Xa kuthelekiswa ne-arc welding, iindleko zokucubungula zingancitshiswa malunga ne-30%. Umsebenzi kulula ukuwufunda kwaye ukhawuleza ukuwusebenzisa, kwaye umda wobugcisa wabaqhubi awukho phezulu. Abasebenzi abaqhelekileyo banokuya emsebenzini emva koqeqesho olufutshane, kwaye banokufikelela ngokulula kwiziphumo eziphezulu ze-welding.

2.Uluhlu olubanzi lwe-welding

Intloko yomatshini we-laser welding ephathwayo ixhotyiswe nge-5m-10m ye-fiber optical yasekuqaleni, eyoyisa umda wendawo yokusebenzela kwaye ingasetyenziselwa ukuwelda ngaphandle kunye ne-welding emide;

3.Easy ukusebenzisa kwaye bhetyebhetye

Umatshini we-laser welding ephathwayo uxhotyiswe ngeepulleys ezihambayo, ezikhululekile ukubamba, kwaye isitishi sinokulungiswa nangaliphi na ixesha ngaphandle kwezikhululo ezisisigxina. Isimahla kwaye ibhetyebhetye, kwaye ifanelekile kwiimeko ezahlukeneyo zokusebenza.

4.Akukho izinto ezisetyenziselwa ukuwelda

Umsebenzi we-welding kwiingqondo zabantu abaninzi "yiiglasi kwisandla sasekhohlo kunye nocingo lwe-welding esandleni sasekunene". Nangona kunjalo, kunye nomatshini we-laser welding welding, i-welding ingagqitywa ngokulula, okunciphisa iindleko zezixhobo zokuvelisa kunye nokusebenza.

5.Unezilumkiso ezininzi zokhuseleko

Umtshini we-touch usebenza kuphela xa i-welding tip ithinta isinyithi, kwaye ukukhanya kuya kuvalwa ngokuzenzekelayo emva kokususa i-workpiece, kwaye i-touch switch ine-sensor yeqondo lokushisa lomzimba. Ukhuseleko oluphezulu, ukuqinisekisa ukhuseleko lomsebenzisi ngexesha lomsebenzi.

6.Iindlela ezahlukeneyo ze-welding

Iyakwazi ukuqaphela i-welding nakweyiphi na i-engile: i-welding ye-stitch, i-welding ye-butt, i-welding ethe nkqo, i-flat fillet welding, i-internal fillet welding, i-outer fillet welding, njl. Qonda i-welding kuyo nayiphi na i-engile. Ukongeza, unokuphinda agqibe ukusika, i-welding kunye nokusika kunokutshintshwa ngokukhululekileyo, tshintsha nje umbhobho wobhedu we-welding kwi-nozzle yobhedu yokusika, efanelekileyo kakhulu.

7.I-Welds ayifuni ukugaya

Emva kwe-welding yesiko, indawo ye-welding kufuneka iphuculwe ukuqinisekisa ukugudiswa kwaye ingabi rhabaxa. Umatshini we-laser welding we-Handheld ubonisa nje iingenelo ezingakumbi kwi-process effect: i-welding eqhubekayo, i-welding egudileyo kwaye akukho sikali sentlanzi, intle kwaye ingenazibazi, inkqubo yokugaya engaphantsi.

8.Isiphumo esihle se-welding

Umatshini wokuwelda welaser ophathwa ngesandla ushushu-unyibilika. Xa kuthelekiswa nokuwelda ngokwesiko, ukuwelda ngelaser kunoxinano lwamandla aphezulu kwaye kunokufikelela kwiziphumo ezingcono zokuwelda. Ummandla welding inempembelelo encinci ye-thermal, akukho lula ukukhubaza, ukumnyama, kwaye kukho imikhondo ngasemva, kwaye ubunzulu be-welding bukhulu. , ukunyibilika okupheleleyo, okuqinileyo kunye nokuthembekileyo, amandla e-weld afikelela okanye agqithise isiseko sesinyithi ngokwawo, esingenakuqinisekiswa ngoomatshini abaqhelekileyo be-welding.

I-welding ebanjwe ngesandla ijolise ikakhulu kwi-laser welding yomgama omde kunye nezixhobo zokusebenza ezinkulu. Iloyisa umda wesithuba sokuhamba sebhentshi yomsebenzi. Indawo echaphazelekayo ukushisa incinci ngexesha le-welding, engayi kubangela ukuguqulwa komsebenzi, i-blackening, kunye nemikhondo emqolo. Ngaphezu koko, ubunzulu be-welding bukhulu kunye ne-Welding Firm kwaye inyibilike ngokupheleleyo, ayinakuqaphela kuphela i-welding conduction yokushisa, kodwa iphinda iqhube i-welding enzulu, i-welding spot, i-butt welding, i-lap welding, i-welding yokutywina, i-welding ye-seam, njl.

Umatshini we-laser welding we-handheld ugcwalisa i-gap kwi-welding ye-welding ye-laser ye-laser industry, ukuphazamisa indlela yokusebenza yomshini we-laser we-welding yendabuko, kwaye unokutshintsha indlela yangaphambili ye-optical esisigxina kunye nomshini obanjwe ngesandla. Ibhetyebhetye ngakumbi kwaye ilungele, kwaye umgama welding mde, nto leyo eyenza ukuba i-laser welding isebenze ngaphandle inokwenzeka.

Ixesha lokuposa: Aug-25-2023