Ubungakanani bedayamitha ye-laser core buya kuchaphazela ilahleko yothumelo kunye nokuhanjiswa koxinzelelo lwamandla okukhanya. Ukukhetha okunengqiqo kwedayimitha engundoqo kubaluleke kakhulu. Ukugqithiswa kwedayimitha engundoqo kuya kukhokelela ekugqwethekeni kwemodi kunye nokusabalalisa kwi-laser transmission, echaphazela umgangatho we-beam kunye nokugxininisa ukuchaneka. Incinci kakhulu idiameter engundoqo iya kubangela I-symmetry ye-optical power density ye-single-mode fiber iba mandundu, engabangeli ukugqithiselai-laser enamandla kakhulu.

1. Izinto eziluncedo kunye nokusetyenziswa kwelaser encinci yedayamitha engundoqo (<100um)

Izinto ezibonisa kakhulu: i-aluminium, ubhedu, insimbi engenasici, i-nickel, i-molybdenum, njl.

(1)Izinto ezibonisa kakhulu kufuneka zikhethe i-laser encinci yedayamitha engundoqo. Umqa we-laser woxinaniso lwamandla aphezulu usetyenziselwa ukufudumeza ngokukhawuleza izinto kwi-liquefied okanye i-vaporized state, ephucula izinga lokufunxa i-laser yezinto kwaye ifezekise ukusebenza ngokufanelekileyo nangokukhawuleza. Ukukhetha i-laser enobubanzi obukhulu obungundoqo kunokukhokelela ngokulula kwimbonakalo ephezulu. , ekhokelela kwi-welding ebonakalayo kunye nokutshiswa kwe-laser;

Izinto ezingevayo kwi-crack: i-nickel, i-nickel-plated copper, i-aluminium, insimbi engenasici, i-titanium alloy, njl.

Esi sixhobo ngokubanzi sidinga ulawulo olungqongqo lwendawo echaphazeleke bubushushu kunye nedama elincinci lokunyibilika, ngoko ke kufanelekile ukukhetha i-laser encinci yedayamitha engundoqo;

Ukusetyenzwa kwe-laser ngesantya esiphezulu:

(3)I-welding yokungena enzulu idinga ukuqhutyelwa kwe-laser ye-high-speed, kwaye kuyimfuneko ukukhetha i-laser ene-high density yamandla ukuqinisekisa ukuba amandla omgca anele ukunyibilikisa izinto ngesantya esiphezulu, ngakumbi kwi-lap welding, i-welding yokungena, njl. ifuna ubunzulu bokungena obuphezulu. Kungcono ukhethe i-laser encinci yedayamitha engundoqo efanelekileyo.

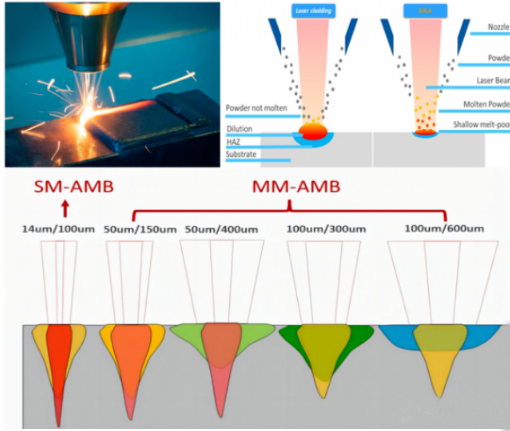

2. Izinto eziluncedo kunye nokusetyenziswa kwelaser enkulu yodayamitha engundoqo (>100um)

Idayimitha engundoqo enkulu kunye nebala elikhulu, indawo enkulu yokugubungela ubushushu, indawo yentshukumo ebanzi, kunye nokunyibilika kancinci komphezulu wezinto ezibonakalayo kuphunyeziweyo, okulungele kakhulu ukusetyenziswa kwi-laser cladding, i-laser annealing, i-laser annealing, ukuqina kwelaser, njl. le mimandla, indawo enkulu yokukhanya ithetha ukusebenza kakuhle kwemveliso kunye neziphene ezisezantsi (i-thermal conductive welding ineziphene phantse akukho).

Ngemimiselo yokubaukuwelda, indawo enkulu isetyenziselwa ikakhuluwelding composite, esetyenziselwa ukudibanisa nge-laser encinci ye-diameter ye-core: indawo enkulu yenza umphezulu wezinto zinyibilike kancinane, ukuguqula ukusuka eqinile ukuya kulwelo, oluphucula kakhulu izinga lokufunxa kwezinto kwi-laser, kwaye ke isebenzisa isiseko esincinci. le nkqubo, ngenxa yokufudumeza kwendawo enkulu, i-post-processing, kunye ne-gradient enkulu yokushisa enikezelwe kwi-pool etyhidiweyo, izinto eziphathekayo azikwazi ukukrazula iziphene ezibangelwa ukufudumeza ngokukhawuleza kunye nokupholisa ngokukhawuleza. Inokwenza imbonakalo ye-weld ibe lula kwaye iphumelele i-spatter ephantsi kunesisombululo se-laser enye.

Ixesha lokuposa: Sep-04-2023