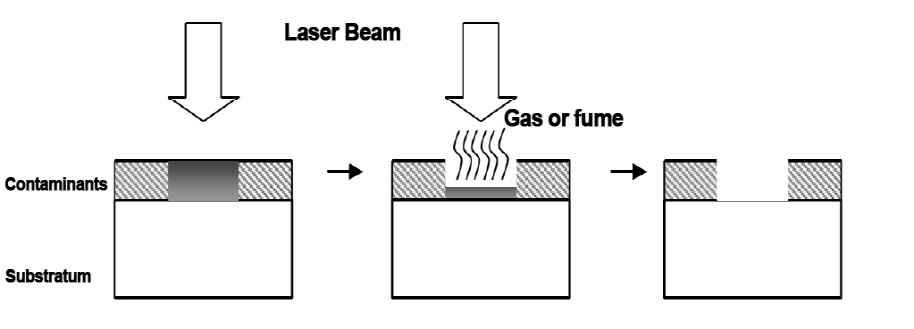

Ukucocwa kweLaser kuyindlela esebenzayo yokususa ubuso obuqinileyo bezinto ezahlukeneyo kunye nobukhulu beengqungquthela ezingcolileyo kunye nefilimu.Ngokuqaqamba okuphezulu kunye nelaser elungileyo eqhubekayo okanye ipulsed laser, ngokujolisa kwi-optical kunye nokubunjwa kwendawo ukwenza imilo ethile yendawo kunye nokuhanjiswa kwamandla kwe-laser beam, iradiated kumphezulu wezinto ezingcolisekileyo ukuze zicocwe, izinto ezingcolisekileyo zifunxa i-laser. amandla, aya kuvelisa uthotho lweenkqubo ezintsonkothileyo zomzimba kunye neekhemikhali ezifana nokungcangcazela, ukunyibilika, ukutsha, kunye nokufakwa kwegesi, kwaye ekugqibeleni wenze ungcoliseko oluvela kumphezulu wezinto ezibonakalayo Nokuba isenzo selaser kumphezulu ocociweyo, uninzi lubonakalisiwe. off, i-substrate ayiyi kubangela umonakalo, ukuze kufezekiswe umphumo wokucoca.Lo mfanekiso ulandelayo: ukususwa komhlwa komphezulu kunye nokucoca.

Ukucocwa kweLaser kunokuhlelwa ngokuhambelana nemigangatho yokuhlela eyahlukeneyo.Njengokuba ngokuhambelana nenkqubo yokucoca i-laser kwi-substrate surface igqunywe ngefilimu engamanzi yahlulwe ngokucoca nge-laser eyomileyo kunye nokucoca nge-laser emanzi.Eyangaphambili i-irradiation ngqo ye-laser surface engcolisekileyo, le yokugqibela kufuneka isetyenziswe kwi-laser yokucoca umphezulu wokufuma okanye ifilimu yolwelo.Ukucocwa kwe-laser okumanzi kokusebenza okuphezulu, kodwa ukucocwa kwe-laser okumanzi kufuna ukugquma ngesandla kwefilimu yolwelo, efuna ukubunjwa kwefilimu yolwelo ayikwazi ukutshintsha ubume be-substrate ngokwayo iyatshintsha.Ke ngoko, ngokunxulumene netekhnoloji eyomileyo yokucoca i-laser, ukucocwa kwe-laser emanzi kunemida ethile kumda wesicelo.Ukucocwa kwe-laser eyomileyo okwangoku yeyona ndlela isetyenziswa kakhulu yokucoca i-laser, esebenzisa umqadi we-laser ukukhupha umphezulu we-workpiece ngokuthe ngqo ukususa amasuntswana kunye neefilimu ezincinci.

ILaserDry Cukungqiyama

Umgaqo osisiseko wokucocwa kwe-laser eyomileyo yi-particle kunye ne-substrate yezinto eziphathekayo nge-laser irradiation, ukuguqulwa kwangoko kwamandla okukhanya afakwe ekushiseni, okubangela i-particle okanye i-substrate okanye zombini ukwanda kwe-thermal kwangoko, phakathi kwe-particle kunye ne-substrate ngokukhawuleza kwavelisa ukukhawuleza, amandla awenziwe ngokukhawulezisa ukunqoba i-adsorption phakathi kwe-particle kunye ne-substrate, ukwenzela ukuba i-particle evela kwi-substrate surface.

Ngokweendlela ezahlukeneyo zokufunxa zokucocwa kwe-laser, ukucocwa kwe-laser kunokohlulwa ngokwezi ndlela zimbini zilandelayo:

1.Fokanye iqondo lokunyibilika likhulu kunemathiriyeli engumzali (okanye ireyithi yokufunxeka kwelaser umahluko) yamasuntswana othuli: amasuntswana afunxa ukukhanya kwelaser yomelele kunokufunxwa kwesubstrate (a) okanye ngokuphendululekileyo (b), ngoko ke amasuntswana afunxa ukukhanya kwelaser. amandla aguqulelwe kumandla ashushu, okubangela ukwanda kwe-thermal kwamasuntswana, nangona inani lokwandiswa kwe-thermal lincinci kakhulu, kodwa ukwanda kwe-thermal kukwixesha elifutshane kakhulu, ngoko kuya kubakho ukukhawuleza okukhulu ngokukhawuleza kwi-substrate, ngelixa I-substrate counter-action kwi-particles, amandla okunqoba amandla okubambisana adsorption, ukwenzela ukuba iinqununu ezivela kwi-substrate, umgaqo womzobo we-schematic njengoko kuboniswe kuMzobo 1.

2. Kwindawo esezantsi yokubilisa yokungcola: ubumdaka bomphezulu bufunxa ngokuthe ngqo amandla e-laser, ubushushu obuphezulu obubilisa ubushushu obuphezulu, i-vaporization ngqo yokususa ukungcola, umgaqo njengoko ubonisiwe kuMfanekiso 2.

ILaserWet CukungqiyamaPrinciple

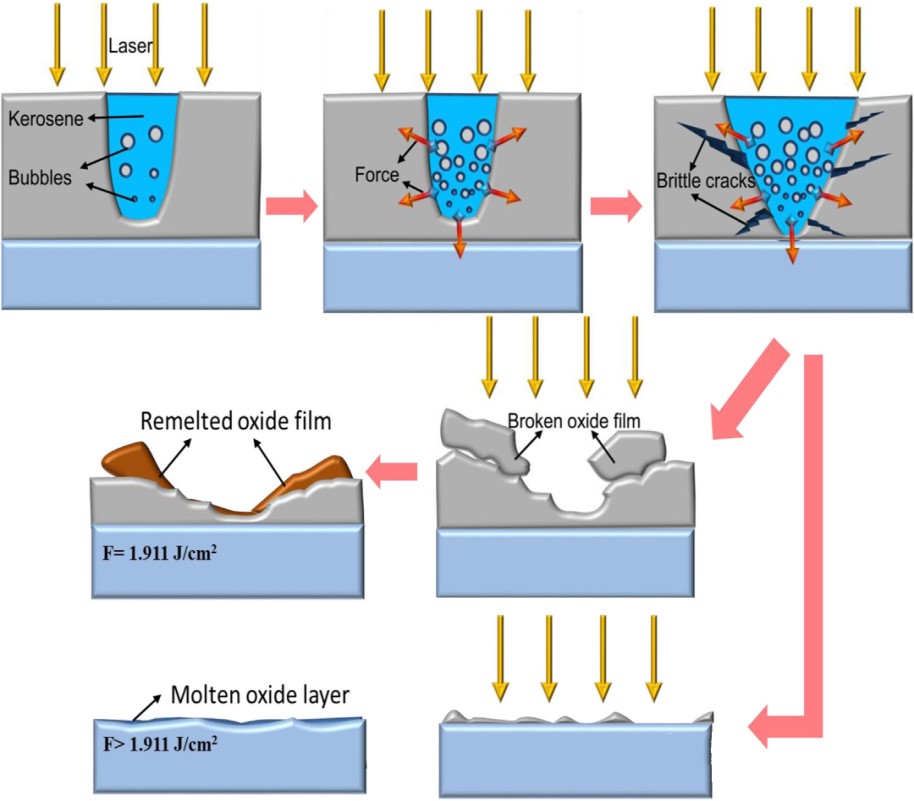

Ukucocwa okumanzi kweLaser kwaziwa njengokucoca umphunga we-laser, ngokuchasene nokomisa, ukucocwa okumanzi kubukho bomaleko obhityileyo wefilimu yolwelo embalwa okanye ifilimu yemidiya kumphezulu weendawo zokucoca, ifilimu elulwelo nge-laser irradiation. Ubushushu befilimu yolwelo bunyuka ngephanyazo kwaye buvelise inani elikhulu lamaqamza kwi-gasification reaction, ugqabhuko-dubulo lwegesi oluveliswa yimpembelelo yamasuntswana kunye ne-substrate ukoyisa amandla e-adsorption phakathi.Ngokwamacandelo, ifilimu ye-liquid kunye ne-substrate kwi-coefficient ye-laser ye-wavelength absorption yahlukile, ukucocwa kwe-laser okumanzi kunokwahlulwa kwiintlobo ezintathu.

1.Ukufunxwa ngamandla kwamandla e-laser nge-substrate

I-Laser irradiation kwi-substrate kunye nefilimu yolwelo, ukufunxwa kwe-laser yi-substrate inkulu kakhulu kunefilimu yolwelo, ngoko ke ukuqhuma kwe-vaporization kwenzeka kwi-interface phakathi kwe-substrate kunye nefilimu yolwelo, njengoko kubonisiwe kumfanekiso ongezantsi.Ngokwethiyori, ukuncipha kwexesha lokubetha kwentliziyo, kokukhona kulula ukuvelisa ukushisa okukhulu kwindawo yokuhlangana, okukhokelela kwimpembelelo enkulu yokudubula.

2. Ukufunxwa okuqinileyo kwamandla e-laser ngenwebu yolwelo

Umgaqo wolu kucoca kukuba ifilimu yolwelo ithatha amandla amaninzi e-laser, kwaye i-vaporization eqhumayo iyenzeka phezu kwefilimu yolwelo, njengoko kuboniswe kumzobo ongezantsi.Ngeli xesha, ukusebenza kakuhle kokucocwa kwe-laser akulunganga njengoko kufakwe kwi-substrate, kuba ngeli xesha impembelelo yokuqhuma kwifilimu yamanzi.Ngelixa i-substrate absorption, i-bubbles kunye nokuqhuma kwenzeka kwi-intersection ye-substrate kunye nefilimu ye-liquid, impembelelo eqhumayo ilula ukutyhala amaqhekeza kude nomphezulu we-substrate, ngoko ke, i-substrate absorption effect yokucoca ingcono.

3.Zombini i-substrate kunye nenwebu yolwelo ngokudibeneyo zifunxa amandla e-laser

Ngeli xesha, ukusebenza kakuhle kokucoca kuphantsi kakhulu, emva kokuba i-laser irradiation kwifilimu yolwelo, inxalenye yamandla e-laser ifunnyiwe, amandla achithwa kwifilimu yolwelo ngaphakathi, ifilimu yolwelo ibilisa ukuvelisa amaqamza, amandla asele e-laser. ngefilimu yolwelo ifunxwa yi-substrate, njengoko kuboniswe kumfanekiso.Le ndlela ifuna amandla amaninzi elaser ukuvelisa amaqamza abilayo phambi kokuba kwenzeke ugqabhuko-dubulo.Ngoko ke ukusebenza kakuhle kwale ndlela kuphantsi kakhulu.

Ukucocwa kwe-laser emanzi kusetyenziswa i-substrate absorption, njengoko uninzi lwamandla e-laser lufunxwa yi-substrate, luya kudala ifilimu elulwelo kunye ne-substrate junction overheating, amaqamza kwi-interface, xa kuthelekiswa nokucocwa okomileyo, okumanzi kukusetyenziswa kokuqhuma kweqamza lokuhlangana. ngempembelelo yokucoca i-laser, ngelixa unokukhetha ukongeza inani elithile lezinto zeekhemikhali kwifilimu yolwelo kunye neengqungquthela ezingcolileyo kwi-chemical reaction ukuze unciphise amaqhekeza kunye ne-substrate Amandla e-adsorption phakathi kwezinto eziphathekayo, ukwenzela ukunciphisa umda we-laser. ukucoca.Ngoko ke, ukucocwa okumanzi kunokuphucula ukusebenza kakuhle kokucoca kwinqanaba elithile, kodwa ngexesha elifanayo kukho ubunzima obuthile, ukuqaliswa kwefilimu ye-liquid kunokukhokelela ekungcoleni okutsha, kwaye ubunzima befilimu ye-liquid kunzima ukuyilawula.

IzintoAichaphazela iQumgangatho weLaserCukungqiyama

Isiphumo seLaserWubude

Isiseko sokucocwa kwe-laser kukufakwa kwe-laser, ke ngoko, ekukhetheni umthombo we-laser, into yokuqala omawuyenze kukudibanisa iimpawu zokufunxa ukukhanya kwendawo yokucoca, khetha i-laser ye-wavelength efanelekileyo njengomthombo wokukhanya kwe-laser.Ukongeza, izazinzulu zakwamanye amazwe uphando lovavanyo lubonisa ukuba ukucoca iimpawu ezifanayo zamasuntswana angcolisekileyo, imfutshane ubude be-wavelength, amandla okucoca anamandla e-laser, asezantsi umda wokucoca.Inokubonwa ukuba, ukuze kuhlangatyezwane neempawu zokufunxa ukukhanya kwesiseko, ukuze kuphuculwe ukusebenza kunye nokusebenza kakuhle kokucoca, kufuneka kukhethe ubude obufutshane be-laser njengomthombo wokukhanya wokucoca.

Isiphumo sePowDamandla

Kwi-laser yokucoca, ukuxinwa kwamandla e-laser kukho umqobo womonakalo ophezulu kunye nomgangatho ophantsi wokucoca.Kolu luhlu, ubuninzi bamandla e-laser bokucoca i-laser, ubukhulu bomthamo wokucoca, kucacile ngakumbi umphumo wokucoca.Ngoko ke akufanele konakalise izinto ze-substrate kwimeko, kufuneka ibe phezulu kangangoko kunokwenzeka ukwandisa ubuninzi bamandla we-laser.

Isiphumo sePulseWidth

I laser Umthombo wokucocwa kwelaser unokuba kukukhanya okuqhubekayo okanye ukukhanya okutyhalwayo, i-pulsed laser inokubonelela ngamandla aphezulu kakhulu, ngoko inokuhlangabezana ngokulula neemfuno zomgubasi.Kwaye kwafunyaniswa ukuba kwinkqubo yokucoca kwi-substrate ebangelwa yimiphumo ye-thermal, i-pulsed laser impact incinci, i-laser eqhubekayo ebangelwa yimpembelelo ye-thermal yommandla inkulu.

IEisiphumo seSukunkonkxaSuchama kwayeNinani leTimes

Ngokucacileyo kwinkqubo yokucoca ngelaser, okukhona isantya sokuskena ngelaser sikhawuleza amaxesha ambalwa, kokukhona siphezulu ukusebenza kakuhle kokucoca, kodwa oku kunokubangela ukwehla kwisiphumo sokucoca.Ngoko ke, kwinkqubo yesicelo sokucoca ngokwenene, kufuneka isekelwe kwiimpawu eziphathekayo zokucoca umsebenzi kunye nemeko yokungcola ukukhetha isantya esifanelekileyo sokuskena kunye nenani lokuskena.Ukuskena ireyithi yokugqithelana njalo njalo kuya kuchaphazela nefuthe lokucoca.

Isiphumo seAintaba yeDegxininisa

Ukucoca i-laser phambi kwelaser ubukhulu becala ngokudityaniswa kwelensi yokujonga ukudibana, kunye neyona nkqubo yokucoca ngelaser, ngokubanzi kwimeko yokungagxinisi, ubukhulu becala lokungagxininisi, ukukhanya kwizinto ezibonakalayo, kokukhona kusiba nkulu indawo. indawo yokuskena, iphezulu ukusebenza kakuhle.Kwaye kumandla apheleleyo aqinisekileyo, encinci ubungakanani bokungagxininisi, ubukhulu bobuninzi bamandla e-laser, bomelele amandla okucoca.

Isishwankathelo

Kuba ukucocwa kwelaser akusebenzisi naziphi na izinyibilikisi zeekhemikhali okanye ezinye izinto ezisetyenziswayo, kukhuselekile kokusingqongileyo, kukhuselekile ukusebenza kwaye kuneengenelo ezininzi kakhulu:

1. eluhlaza kunye nokusingqongileyo, ngaphandle kokusetyenziswa kweekhemikhali kunye nezisombululo zokucoca,

2. ukucoca inkunkuma ikakhulu ngumgubo oqinileyo, ubungakanani obuncinci, kulula ukuqokelelwa kunye nokuphinda kusetyenziswe,

3. Ukucoca umsi wenkunkuma kulula ukufunxa nokuphatha, ingxolo ephantsi, akukho bungozi kwimpilo yomntu,

4. Ukucocwa koqhagamshelwano, akukho ntsalela yemidiya, akukho ngcoliseko lwesibini,

5. Ukucoca okukhethiweyo kunokufezekiswa, akukho monakalo kwi-substrates,

6. Akukho ukusetyenziswa okuphakathi okusebenzayo, kusebenzisa umbane kuphela, iindleko eziphantsi zokusetyenziswa kunye nokugcinwa,

7. Easy ukufikelela kwi-automation, ukunciphisa ukuqina kwabasebenzi,

8. Ifanele iindawo ekunzima ukufikelela kuzo okanye imiphezulu, kwindawo enobungozi okanye enobungozi.

I-Maven Laser Automation Co., Ltd. ngumvelisi oqeqeshiweyo womatshini we-laser welding, umatshini wokucoca i-laser, umatshini wokumakisha we-laser iminyaka eyi-14.Ukusukela ngo-2008, iMaven Laser igxile ekuphuhliseni nasekuveliseni iintlobo ngeentlobo ze-laser engraving/welding/marking/coca umatshini onolawulo oluphezulu, amandla ophando olomeleleyo kunye nesicwangciso esizinzileyo sokudityaniswa kwehlabathi, iMaven Laser iseka ukuthengiswa kwemveliso egqibeleleyo kunye nenkqubo yenkonzo eTshayina kwaye kwihlabathi jikelele, yenza uphawu lwehlabathi kushishino lwelaser.

Ngaphaya koko, sinikela ingqalelo enkulu kwinkonzo yasemva kokuthengisa, Inkonzo elungileyo kunye nomgangatho olungileyo zibalulekile ngokufanayo kwiMaven Laser iya kulandela umoya "Ukuthembeka kunye neMfezeko", zama kangangoko ukubonelela abathengi ngemveliso ephezulu kunye nenkonzo engcono.

I-Maven Laser - umthengisi wezixhobo zeLaser ezithembekileyo!

Wamkelekile ukusebenzisana nathi kwaye uphumelele ukuphumelela.

Ixesha lokuposa: May-05-2023