Kwiminyaka yakutshanje, ngenxa yophuhliso olukhawulezayo lweshishini elitsha lamandla, i-laser welding iye yangena ngokukhawuleza kwishishini elitsha lamandla ngenxa yeenzuzo zayo ezikhawulezayo nezizinzileyo. Phakathi kwazo, izixhobo ze-laser welding akhawunti yeyona nxalenye iphezulu yezicelo kwishishini elitsha lamandla.

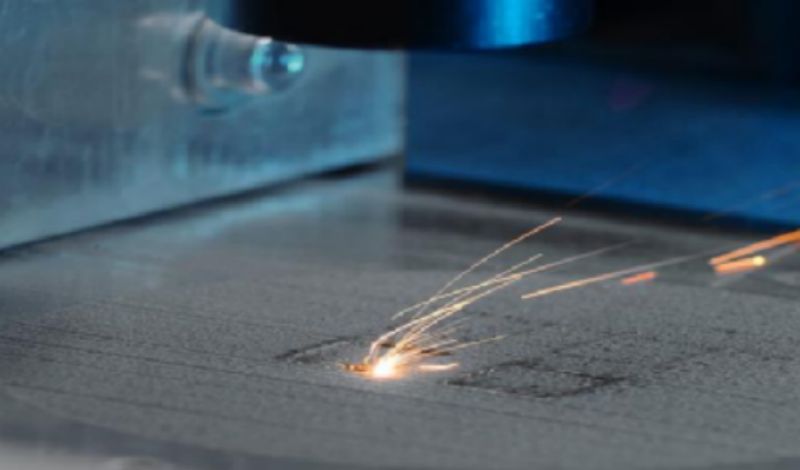

Ukuwelda kweLaseriye yakhawuleza yaba lukhetho lokuqala kuzo zonke iinkalo zobomi ngenxa yesantya sayo, ubunzulu obukhulu, kunye noguquko oluncinci. Ukusuka kwiindawo zokuwelda ukuya kwiiwelds ze-butt, ukwakhiwa kunye nokutywinwa kwe-welds,welding laserinikeza ukuchaneka okungenakulinganiswa kunye nolawulo. Idlala indima ebalulekileyo kwimveliso yemizi-mveliso kunye nemveliso, kubandakanywa imboni yezomkhosi, unyango, i-aerospace, iinxalenye zemoto ze-3C, i-mechanical sheet metal, amandla amatsha kunye namanye amashishini.

Xa kuthelekiswa nobunye ubugcisa bokuwelda, i-laser welding ineengenelo zayo ezizodwa kunye nezingeloncedo.

I-advanteji:

1. Ukukhawuleza ngokukhawuleza, ubunzulu obukhulu kunye ne-deformation encinci.

2. I-Welding inokwenziwa kwiqondo lokushisa eliqhelekileyo okanye phantsi kweemeko ezikhethekileyo, kunye nezixhobo ze-welding zilula. Umzekelo, umqa welaser awukhukuli kwindawo ye-electromagnetic. IiLaser zinokuwelda kwindawo efunxayo, emoyeni okanye kwindawo ethile yerhasi, kwaye ziyakwazi ukuwelda izinto ezenziwe ngeglasi okanye zibonakale ngaphaya komqadi welaser.

3. Iyakwazi ukuwelda imathiriyeli ye-refractory efana ne-titanium kunye ne-quartz, kwaye inokuphinda idibanise izinto ezahlukeneyo kunye neziphumo ezilungileyo.

4. Emva kokuba i-laser igxininiswe, ubuninzi bamandla buphezulu. Umyinge we-aspect ratio unokufikelela kwi-5: 1, kwaye unokufikelela kwi-10: 1 xa udibanisa izixhobo eziphezulu zamandla.

5. I-Micro welding inokwenziwa. Emva kokuba i-laser beam igxininiswe, indawo encinci inokufumaneka kwaye inokubekwa ngokuchanekileyo. Inokuthi isetyenziswe kwindibano kunye ne-welding ye-micro kunye ne-workpieces encinci ukufezekisa imveliso yobuninzi ezenzekelayo.

6. Iyakwazi ukuthunga iindawo ezinzima ukufikelela kuzo kwaye yenze i-welding ye-long-distance-welding, kunye nokuguquguquka okukhulu. Ngokukodwa kule minyaka yamva nje, itekhnoloji yokusetyenzwa kwelaser ye-YAG yamkele itekhnoloji yokuhanjiswa kwefiber optical, eyenze ukuba itekhnoloji ye-laser welding ikhuthazwe kwaye isetyenziswe ngokubanzi.

7. I-laser beam kulula ukwahlula ngexesha kunye nendawo, kwaye imiqadi emininzi inokucutshungulwa kwiindawo ezininzi ngaxeshanye, ibonelela ngeemeko zokudibanisa ngokuchanekileyo.

Isiphene:

1. Ukuchaneka kwendibano ye-workpiece kufuneka ibe phezulu, kwaye indawo ye-boam kwi-workpiece ayikwazi ukuphambuka kakhulu. Oku kungenxa yokuba ubungakanani bendawo yelaser emva kokujolisa buncinci kwaye i-weld seam imxinwa, nto leyo eyenza kube nzima ukongeza imathiriyeli yesinyithi. Ukuba ukuchaneka kwendibano ye-workpiece okanye ukuchaneka kokubeka umqadi akuhambelani neemfuno, iziphene ze-welding ziyakwazi ukwenzeka.

2. Iindleko zeelaser kunye neenkqubo ezinxulumene nazo ziphezulu, kwaye utyalo-mali lwexesha elinye lukhulu.

Iziphene ze-laser welding eziqhelekileyokwimveliso yebhetri ye-lithium

1. I-Welding porosity

Iziphene eziqhelekileyo kwiwelding laserzi pores. Idama elinyibilikayo lokuwelda linzulu kwaye limxinwa. Ngethuba lenkqubo ye-laser welding, i-nitrogen ihlasela i-pool etyhidiweyo ngaphandle. Ngexesha lokupholisa kunye nenkqubo yokuqinisa isinyithi, ukunyibilika kwe-nitrogen kuncipha ngokuhla kweqondo lobushushu. Xa isinyithi sechibi esityhidiweyo sipholile ukuqala ukukhazimla, , ukunyibilika kuya kuhla ngokukhawuleza kwaye ngokukhawuleza. Ngeli xesha, isixa esikhulu serhasi siya kukhawuleza senze amaqamza. Ukuba isantya esidadayo samaqamza singaphantsi kwesantya secrystallization yesinyithi, iipores ziya kuveliswa.

Kwizicelo kwishishini lebhetri ye-lithium, sihlala sifumanisa ukuba iipores zinokwenzeka ngokukodwa ngexesha lokutshisa i-electrode efanelekileyo, kodwa kunqabile ukuba kwenzeke ngexesha lokutshisa i-electrode engalunganga. Oku kungenxa yokuba i-electrode efanelekileyo yenziwe nge-aluminiyam kwaye i-electrode engalunganga yenziwe ngobhedu. Ngexesha le-welding, i-aluminium engamanzi phezu komhlaba iyancipha ngaphambi kokuba i-gas yangaphakathi iphuphume ngokupheleleyo, ikhusela i-gas ekuphuphumeni kwaye yenze imingxuma emikhulu kunye nencinci. Istomata esincinci.

Ukongeza kwizizathu ze-pores ezikhankanywe ngasentla, ii-pores nazo zibandakanya umoya wangaphandle, ukufuma, i-oyile engaphezulu, njl njl. Ukongeza, ulwalathiso kunye ne-angle yokuvuthela kwe-nitrogen kuya kuchaphazela ukubunjwa kwee-pores.

Ngokuphathelele indlela yokunciphisa ukwenzeka kwee-welding pores?

Okokuqala, ngaphambiliukuwelda, ukungcola kweoli kunye nokungcola ebusweni bezinto ezingenayo kufuneka zihlambuluke ngexesha; ekuveliseni iibhetri ze-lithium, ukuhlolwa kwezinto ezingenayo yinkqubo ebalulekileyo.

Okwesibini, ukuhamba kwegesi yokukhusela kufuneka kulungiswe ngokwezinto ezifana nesantya se-welding, amandla, isikhundla, njl., kwaye akufanele kube mkhulu kakhulu okanye kuncinci. Uxinzelelo lwengubo ekhuselayo kufuneka luhlengahlengiswe ngokwezinto ezifana namandla e-laser kunye nesikhundla sokugxila, kwaye akufanele kube phezulu kakhulu okanye kuphantsi kakhulu. Ubume bombhobho okhuselayo kufuneka ulungelelaniswe ngokwemilo, isalathiso kunye nezinye izinto ze-weld ukwenzela ukuba ingubo yokukhusela ikwazi ukugubungela ngokulinganayo indawo yokudibanisa.

Okwesithathu, lawula ubushushu, ukufuma kunye nothuli emoyeni kwindawo yokusebenzela. Ubushushu be-ambient kunye nokufuma kuya kuchaphazela umxholo wokufuma kumphezulu we-substrate kunye negesi yokukhusela, eya kuthi ichaphazele isizukulwana kunye nokuphunyuka komphunga wamanzi kwi-pool etyhidiweyo. Ukuba ubushushu be-ambient kunye nomswakama buphezulu kakhulu, kuya kubakho umswakama obuninzi phezu kwe-substrate kunye negesi ekhuselayo, evelisa umthamo omkhulu womphunga wamanzi, obangela iipores. Ukuba ubushushu be-ambient kunye nomswakama uphantsi kakhulu, kuya kubakho ukufuma okuncinci kumphezulu we-substrate kunye negesi ekhuselayo, ukunciphisa ukuveliswa komphunga wamanzi, ngaloo ndlela kuncitshiswe ama-pores; vumela abasebenzi bekhwalithi ukuba babone ixabiso elijoliswe kuyo lobushushu, ukufuma kunye nothuli kwisikhululo se-welding.

Okwesine, indlela yokujingi ye-beam isetyenziselwa ukunciphisa okanye ukuphelisa ii-pores kwi-laser ye-deep penetration welding. Ngenxa yokongezwa kwe-swing ngexesha le-welding, i-swing ye-reciprocating ye-beam ukuya kwi-weld seam ibangela ukuphindaphinda ngokuphindaphindiweyo kwenxalenye ye-weld seam, eyandisa ixesha lokuhlala lesinyithi solwelo kwi-welding pool. Ngelo xesha, ukuphambuka kwe-beam kwandisa igalelo lokushisa kwindawo nganye yeyunithi. Umlinganiselo wobunzulu ukuya kububanzi be-weld uyancitshiswa, ohambelana nokuvela kwamabhubhu, ngaloo ndlela ukuphelisa iipores. Ngakolunye uhlangothi, ukuguquka komqadi kubangela ukuba umngxuma omncinci ujike ngokufanelekileyo, onokunika amandla ashukumisayo echibini le-welding, ukwandisa i-convection kunye nokuvuselela i-welding pool, kwaye ibe nefuthe elihle ekupheliseni ama-pores.

Okwesihlanu, i-pulse frequency, i-pulse frequency ibhekisa kwinani lee-pulses ezikhutshwe yi-laser beam ngexesha leyunithi, eliya kuchaphazela igalelo lobushushu kunye nokuqokelelwa kobushushu echibini elityhidiweyo, kwaye emva koko kuchaphazele intsimi yobushushu kunye nentsimi yokuhamba kwindawo etyhidiweyo. ichibi. Ukuba i-pulse frequency iphezulu kakhulu, iya kukhokelela kwigalelo lobushushu eligqithisileyo kwidama elinyibilikisiweyo, libangela ubushushu bechibi elinyibilikisiweyo libe phezulu kakhulu, livelise umphunga wesinyithi okanye ezinye izinto eziguquguqukayo kumaqondo aphezulu, okukhokelela kwiipores. Ukuba i-pulse frequency iphantsi kakhulu, iya kukhokelela ekuqokeleleni kobushushu obungonelanga kwidama elinyibilikisiweyo, okubangela ukuba ubushushu bechibi elinyibilikisiweyo bube sezantsi kakhulu, ukunciphisa ukunyibilika kunye nokubaleka kwerhasi, okukhokelela kwiipores. Ngokubanzi, i-pulse frequency kufuneka ikhethwe ngaphakathi koluhlu olufanelekileyo olusekwe kubukhulu be-substrate kunye namandla e-laser, kwaye uphephe ukuba phezulu kakhulu okanye usezantsi kakhulu.

Imingxuma yokuwelda (i-laser welding)

2. I-weld spatter

I-spatter eyenziwe ngexesha lenkqubo ye-welding, i-laser welding iya kuchaphazela kakhulu umgangatho we-weld, kwaye iya kungcolisa kwaye yonakalise i-lens. Ukusebenza ngokubanzi ngolu hlobo lulandelayo: emva kokuba i-laser welding igqityiwe, iinqununu ezininzi zetsimbi zivela kumphezulu wezinto eziphathekayo okanye i-workpiece kwaye zibambelele kumphezulu wezinto okanye i-workpiece. Ukusebenza okubonakalayo kukuba xa u-welding kwimo ye-galvanometer, emva kwexesha lokusetyenziswa kwe-lens yokukhusela ye-galvanometer, kuya kubakho imigodi exineneyo phezu komhlaba, kwaye le mibhobho ibangelwa yi-welding spatter. Emva kwexesha elide, kulula ukuvala ukukhanya, kwaye kuya kubakho iingxaki ngokukhanya kwe-welding, okukhokelela kuluhlu lweengxaki ezifana ne-welding ephukileyo kunye ne-welding virtual.

Zeziphi izizathu zokutshiza?

Okokuqala, uxinaniso lwamandla, okukhona uxinaniso lwamandla lukhulu, kokukhona kulula ukuvelisa i-spatter, kwaye isitshizi sinxulumene ngokuthe ngqo noxinaniso lwamandla. Le yingxaki yenkulungwane endala. Ubuncinci ukuza kuthi ga ngoku, ishishini alikwazanga ukusombulula ingxaki yokutshiza, kwaye linokuthi lincitshiswe kancinci. Kwishishini lebhetri ye-lithium, ukutshiza yeyona nto ibangela ibhetri emfutshane, kodwa ayikwazanga ukucombulula unobangela. Impembelelo ye-spatter kwibhetri ingancitshiswa kuphela ukusuka kwindawo yokujonga ukukhusela. Umzekelo, isangqa sezibuko zokususa uthuli kunye nezikhuselo ezikhuselayo zongezwa malunga nenxalenye ye-welding, kwaye imiqolo yeemela zomoya zongezwa kwizangqa ukuthintela impembelelo ye-spatter okanye umonakalo kwibhetri. Ukutshabalalisa indalo, iimveliso kunye namacandelo ajikeleze isikhululo se-welding kunokuthiwa kuphelile iindlela.

Ngokuphathelele ukusombulula ingxaki ye-spatter, kunokutshiwo kuphela ukuba ukunciphisa amandla e-welding kunceda ukunciphisa i-spatter. Ukunciphisa isantya se-welding kunokunceda ukuba ukungena akwanelanga. Kodwa kwezinye iimfuno zenkqubo ekhethekileyo, inempembelelo encinci. Yinkqubo efanayo, oomatshini abahlukeneyo kunye neebhetshi ezahlukeneyo zezixhobo zineempembelelo ze-welding ezahlukeneyo ngokupheleleyo. Ke ngoko, kukho umgaqo ongabhalwanga kwishishini elitsha lamandla, iseti enye yeeparamitha ze-welding kwisixhobo esinye.

Okwesibini, ukuba umphezulu wezinto ezicwangcisiweyo okanye i-workpiece ayicocwanga, amabala e-oyile okanye izinto ezingcolisayo nazo ziya kubangela i-splashes enzulu. Ngeli xesha, into elula kakhulu kukucoca ubuso bezinto ezicwangcisiweyo.

3. Ukubonakala okuphezulu kwe-laser welding

Ngokubanzi, ukubonakaliswa okuphezulu kubhekiselele kwinto yokuba imathiriyeli yokulungisa inokumelana okuncinci, indawo egudileyo, kunye nenqanaba elisezantsi lokufunxa kwiilaser ezikufutshane ne-infrared, ezikhokelela kwisixa esikhulu sokukhutshwa kwelaser, kwaye ngenxa yokuba kusetyenziswa iilaser ezininzi. ngokuthe nkqo Ngenxa yempahla okanye isixa esincinci sokuthambekela, ukukhanya kwelaser ebuyayo kungena kwakhona kwintloko ephumayo, kwaye nenxalenye yokukhanya okubuyayo kudityaniswa kwifayibha yokuhambisa amandla, kwaye igqithiselwa ngasemva kunye nefiber ngaphakathi. yelaser, ukwenza amacandelo aphambili ngaphakathi kwelaser aqhubeke nokuba kubushushu obuphezulu.

Xa ukubonakaliswa kuphezulu kakhulu ngexesha le-laser welding, ezi zisombululo zilandelayo zinokuthathwa:

3.1 Sebenzisa i-anti-reflection coating okanye uphathe umphezulu wezinto eziphathekayo: ukugubungela umphezulu we-welding material kunye ne-anti-reflection coating inokunciphisa ngempumelelo i-reflection ye-laser. Olu tyaba ludla ngokuba yinto ekhethekileyo ye-optical material kunye ne-reflection ephantsi efunxa amandla e-laser endaweni yokuyibonakalisa ngasemva. Kwezinye iinkqubo, ezifana ne-welding yangoku yomqokeleli, uxhulumaniso oluthambileyo, njl., Umphezulu unokuphinda ugxininiswe.

3.2 Lungisa i-angle ye-welding: Ngokuhlengahlengisa i-angle ye-welding, i-laser beam inokuba yisiganeko kwizinto ze-welding kwi-angle efanelekileyo ngakumbi kunye nokunciphisa ukwenzeka kokubonisa. Ngokwesiqhelo, ukuba nesehlo se-laser beam perpendicularly to the surface of the material to be welded yindlela elungileyo yokunciphisa ukubonakaliswa.

3.3 Ukongeza i-absorbent encedisayo: Ngethuba lenkqubo ye-welding, inani elithile le-absorbent encedisayo, njengomgubo okanye i-liquid, yongezwa kwi-weld. Ezi zihluzi zifunxa amandla e-laser kwaye zinciphise ukubonakalisa. I-absorbent efanelekileyo kufuneka ikhethwe ngokusekelwe kwizinto ezithile ze-welding kunye neemeko zesicelo. Kwishishini lebhetri ye-lithium, oku akunakwenzeka.

I-3.4 Sebenzisa i-fiber optical ukuhambisa i-laser: Ukuba kunokwenzeka, i-fiber optical ingasetyenziselwa ukuhambisa i-laser kwindawo ye-welding ukunciphisa ukubonakaliswa. Imicu ye-Optical inokukhokela i-laser beam ukuya kwindawo ye-welding ukuphepha ukuvezwa ngokuthe ngqo kumphezulu we-welding material kunye nokunciphisa ukuvela kokubonakaliswa.

3.5 Ukulungelelanisa iiparamitha ze-laser: Ngokuhlengahlengisa iiparitha ezifana namandla e-laser, ubude obugxilwe, kunye nobubanzi obugxininisekileyo, ukuhanjiswa kwamandla e-laser kunokulawulwa kwaye ukubonakaliswa kunokunciphisa. Kwezinye izinto ezibonisayo, ukunciphisa amandla e-laser kunokuba yindlela esebenzayo yokunciphisa ukubonakaliswa.

3.6 Sebenzisa i-beam splitter: I-beam splitter inokukhokela inxalenye yamandla e-laser kwisixhobo sokufunxa, ngaloo ndlela inciphisa ukwenzeka kokubonakaliswa. Izixhobo zokwahlula i-Beam zihlala zibandakanya amacandelo optical kunye ne-absorber, kwaye ngokukhetha amacandelo afanelekileyo kunye nokulungelelanisa uyilo lwesixhobo, ukubonakaliswa okuphantsi kunokufezekiswa.

4. Welding undercut

Kwinkqubo yokuvelisa ibhetri ye-lithium, zeziphi iinkqubo ezinokuthi zenze ukuba ngaphantsi kwe-undercutting? Kutheni i-undercutting isenzeka? Makhe siyihlalutye.

I-Undercut, ngokubanzi izixhobo zokuwelda azidityaniswanga kakuhle, umsantsa mkhulu kakhulu okanye umsele ubonakala, ubunzulu nobubanzi bungaphezulu kwe-0.5mm, ubude bubonke bungaphezulu kwe-10% yobude be-weld, okanye mkhulu kunomgangatho wenkqubo yemveliso ubude obuceliweyo.

Kuyo yonke inkqubo yokuvelisa ibhetri ye-lithium, ukusika ngaphantsi kunokwenzeka ngakumbi, kwaye ngokubanzi isasazwa ekutywinweni kwangaphambili kunye nokuwelda kwepleyiti yesigqubuthelo esisilinda kunye nokutywinwa kwangaphambili kunye nokuwelda kwepleyiti yesigqubuthelo se-aluminium yesikwere. Esona sizathu sikukuba ipleyiti yokutywina yokutywina idinga ukusebenzisana neqokobhe ukuya kwi-Welding, inkqubo yokudibanisa phakathi kwepleyiti yokutywina kunye neqokobhe liqhelekile kwizikhewu ezigqithisiweyo ze-weld, iigrooves, ukuwa, njl. .

Ke yintoni ebangela undercutting?

Ukuba isantya welding ikhawuleza kakhulu, isinyithi elulwelo emva umngxuma encinane esalatha embindini weld akayi kuba nexesha lokusasaza kwakhona, okubangela ukuqina kunye undercutting macala omabini weld. Ngokujonga le meko ingentla, kufuneka siphucule iiparamitha ze-welding. Ukuyibeka ngokulula, iphinda-phinda imifuniselo yokuqinisekisa iiparamitha ezahlukeneyo, kwaye qhubeka usenza i-DOE de iiparamitha ezifanelekileyo zifunyenwe.

2. Izikhewu ezigqithisiweyo ze-weld, i-grooves, i-collapses, njl. Izinto ze-welding ziya kunciphisa ubuninzi besinyithi esinyibilikisiweyo sokuzalisa izithuba, okwenza i-undercuts inokwenzeka ngakumbi. Lo ngumbuzo wezixhobo kunye nezinto eziluhlaza. Ingaba izinto ze-welding ekrwada ziyahlangabezana neemfuno zezinto ezingenayo zenkqubo yethu, nokuba ukuchaneka kwezixhobo kuyahlangabezana neemfuno, njl njl. Umkhuba oqhelekileyo kukuhlala uthuthumbisa kwaye ubethe ababoneleli kunye nabantu abaphethe izixhobo.

3. Ukuba amandla ehla ngokukhawuleza ekupheleni kwe-laser welding, umngxuma omncinci unokudilika, okukhokelela kwi-undercutting yendawo. Ukulinganisa okuchanekileyo kwamandla kunye nesantya kunokuthintela ngokufanelekileyo ukubunjwa kwee-undercuts. Njengoko ilizwi lakudala lihamba, phinda imifuniselo, qinisekisa iiparamitha ezahlukeneyo, kwaye uqhubeke DOE de ufumane iiparamitha ezifanelekileyo.

5. Ukuwa kweweld centre

Ukuba isantya se-welding sicotha, i-pool etyhidiweyo iya kuba nkulu kwaye ibe banzi, ikhulise inani lesinyithi esityhidiweyo. Oku kunokwenza ugcino lwexinzelelo lomphezulu lubenzima. Xa isinyithi esinyibilikisiweyo sisiba nzima kakhulu, umbindi we weld unokutshona kwaye wenze iidiphu kunye nemingxuma. Kule meko, ubuninzi bamandla kufuneka buncitshiswe ngokufanelekileyo ukunqanda ukuwa kwe-melt pool.

Kwenye imeko, i-gap ye-welding yenza nje ukuwa ngaphandle kokubangela ukuqhuma. Oku ngokungathandabuzekiyo yingxaki yezixhobo zokucofa.

Ukuqonda okufanelekileyo kweziphene ezinokuthi zenzeke ngexesha le-laser welding kunye nezizathu zeziphene ezahlukeneyo zivumela indlela ekujoliswe kuyo ekusombululeni naziphi na iingxaki ze-welding ezingaqhelekanga.

6. Weld iintanda

Iintanda ezivela ngexesha lelaser welding eqhubekayo ziziintanda ze-thermal, ezinje ngekristale kunye nokuqhekeka kwe-liquefaction. Oyena nobangela wolu qhekeko yimikhosi emikhulu yokuncipha eyenziwe yi-weld ngaphambi kokuba iqine ngokupheleleyo.

Kukwakho ezi zizathu zilandelayo zokuqhekeka kwe-laser welding:

1. Uyilo lwe-weld olungenangqiqo: Uyilo olungafanelekanga lwejometri kunye nobukhulu be-weld bunokubangela uxinzelelo lwe-welding, ngaloo ndlela lubangele ukuqhekeka. Isisombululo kukwandisa uyilo lwe-weld ukunqanda ukuxinana koxinzelelo lwe-welding. Ungasebenzisa i-weld ye-offset efanelekileyo, utshintshe imilo ye-weld, njl.

2. Ukungafani kweeparamitha ze-welding: Ukukhetha okungafanelekanga kweeparameters ze-welding, ezifana nesantya esikhawulezayo se-welding, amandla aphezulu kakhulu, njl. Isisombululo kukulungelelanisa iiparitha ze-welding ukuze zihambelane nezinto ezithile kunye neemeko ze-welding.

3. Ukulungiswa okungalunganga kwe-welding surface: Ukungaphumeleli ukucoceka ngokufanelekileyo kunye nokuphatha kwangaphambili i-welding surface ngaphambi kwe-welding, njengokususa i-oxides, igrisi, njl., kuya kuchaphazela umgangatho kunye namandla e-weld kwaye kulula ukukhokelela ekuqhekekeni. Isisombululo kukucoca ngokufanelekileyo kunye nokuphatha kwangaphambili i-welding surface ukuqinisekisa ukuba ukungcola kunye nokungcola kwindawo ye-welding iphathwa ngokufanelekileyo.

4. Ukulawulwa okungafanelekanga kwegalelo lobushushu be-welding: Ukulawulwa kakubi kwegalelo lokushisa ngexesha lokutshisa, njengokushisa okugqithisileyo ngexesha le-welding, izinga lokupholisa elingafanelekanga le-welding layer, njl., kuya kukhokelela ekutshintsheni kwisakhiwo sendawo ye-welding, okubangelwa ukuqhekeka. . Isisombululo kukulawula izinga lokushisa kunye nokupholisa ngexesha le-welding ukuphepha ukufudumala kunye nokupholisa ngokukhawuleza.

5. Ukunciphisa uxinzelelo olungonelanga: Ukungonelanga unyango lokunyanzeliswa kwengcinezelo emva kwe-welding kuya kubangela ukungonelanga koxinzelelo kwindawo edibeneyo, eya kubangela lula ukuqhekeka. Isisombululo kukwenza unyango olufanelekileyo lokunciphisa uxinzelelo emva kwe-welding, njengonyango lokushisa okanye unyango lwe-vibration (esona sizathu).

Ngokuphathelele inkqubo yokuvelisa iibhetri ze-lithium, zeziphi iinkqubo ezinokuthi zibangele ukuqhekeka?

Ngokuqhelekileyo, iintanda zivame ukwenzeka ngexesha lokutywinwa kwe-welding, njengokutywinwa kwe-welding ye-cylindrical steel shells okanye i-aluminium igobolondo, ukutywinwa kweegobolondo ze-aluminium yesikwere, njl. ukuya kwiintanda.

Kakade ke, sinokusebenzisa i-filler wire, preheating okanye ezinye iindlela zokunciphisa okanye ukuphelisa ezi ntanda.

Ixesha lokuposa: Sep-01-2023