Umatshini wokuWelding weLaser weRobhothi

Iimpawu zesiXhobo:

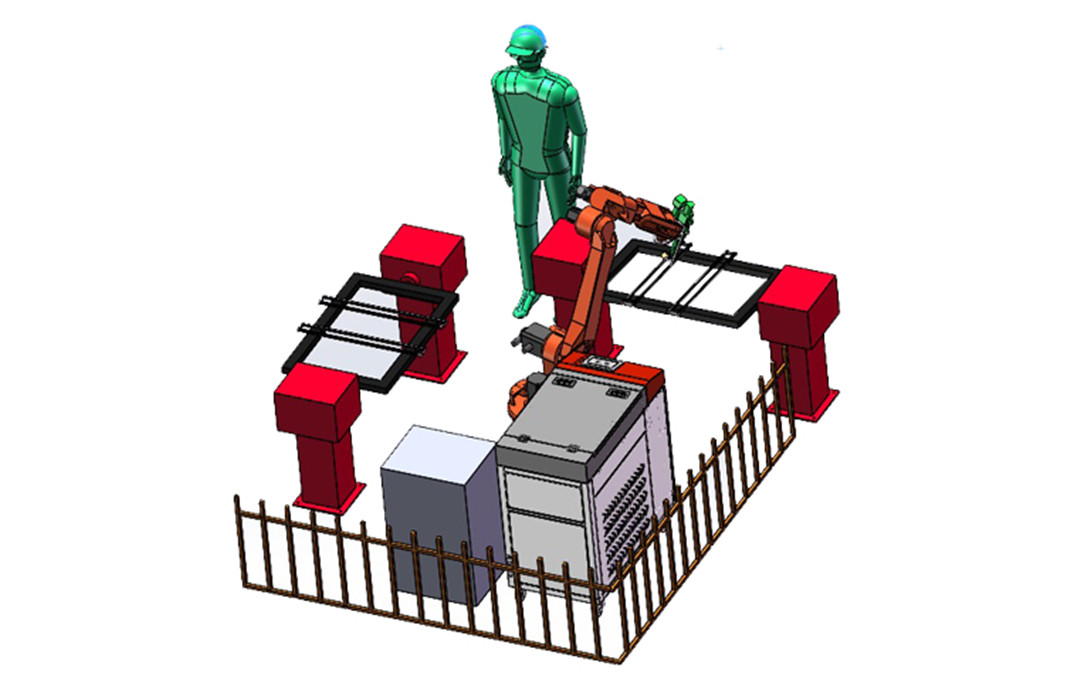

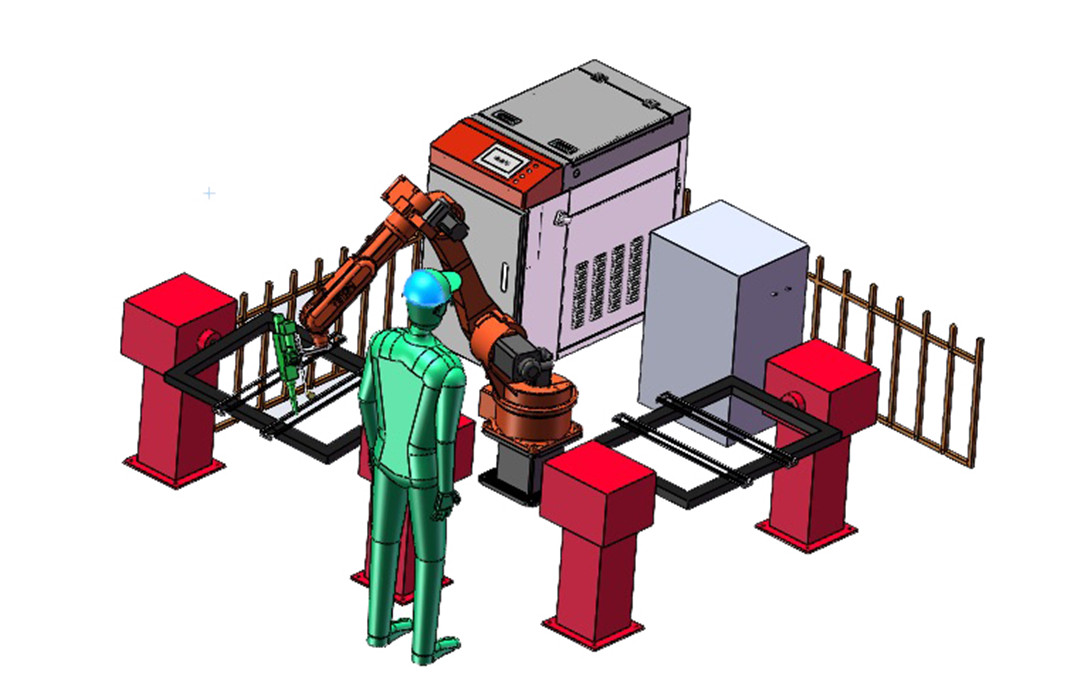

1. Ukusebenzisa i-robotic movement, ifanelekile kwi-welding space-fomati enkulu, ingaba yi-6-axis linkage.

2. Ngaba i-weld kuyo nayiphi na indawo, iqonde ngokwenene i-welding ezenzekelayo yayo nayiphi na i-trajectory kwindawo.

3. Ukuchaneka okuphindaphindiweyo kokuphindaphinda, kunokuphinda i-welding ngamaxesha amaninzi ngaphandle kwephutha, umgangatho we-weld uzinzile.

4. Iyakwazi ukuthatha indawo yokusebenza ngesandla, kwaye ingakwazi i-laser weld complex kunye namasimi ayingozi.

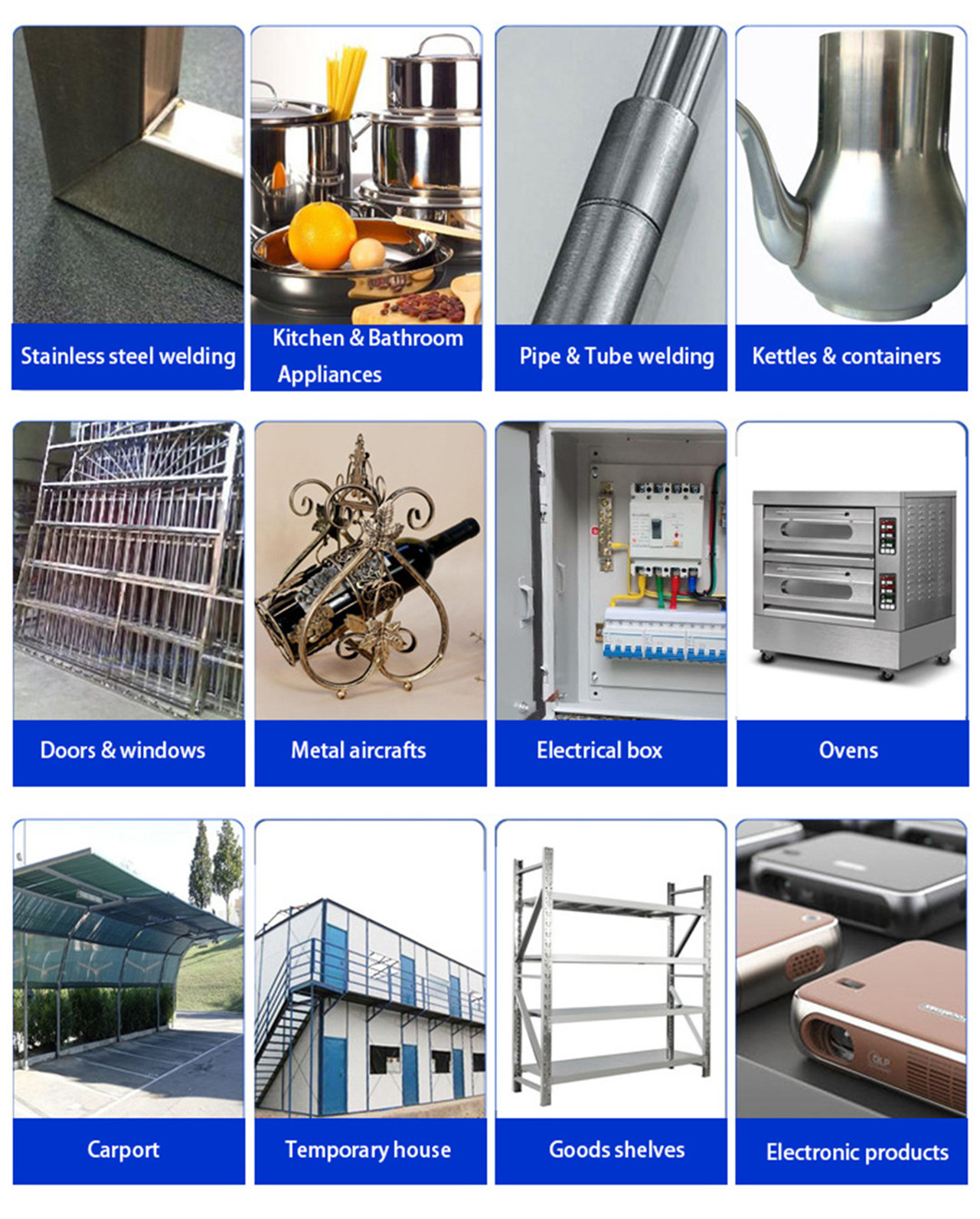

Iindawo zesicelo:

Umzimba ozenzekelayo, ipleyiti yentsimbi ye-auto, ipleyiti ye-clutch, amasimi e-welding anzima kwaye anzima, amacandelo e-microelectronic, amacandelo achanekileyo, amacandelo aphezulu edijithali, izihlanganisi ze-fiber optic, izixhobo zonyango, i-welding enkulu yokubumba, ukubunjwa kwenaliti kunye nokunye ukuwelda.

INKCAZELO YE-WELDDING YOBUCHULE

I-Fire Feeder kunye ne-Welding egxininiswe kwi-Pedal yokulawula

0.08mm Robot Positioning Ukuchaneka

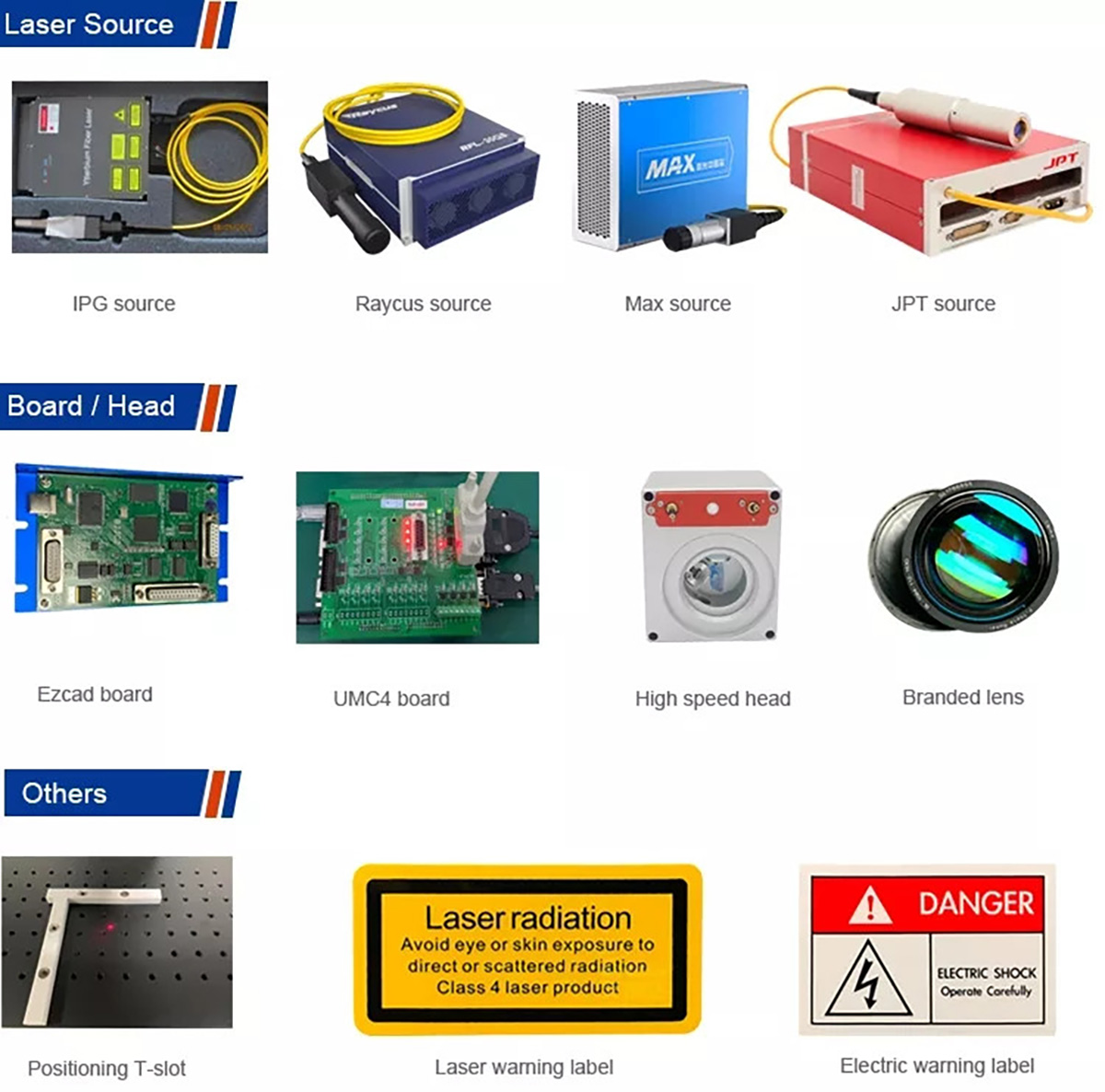

Raycus Max JPT IPG Laser Source Optional

Ukwenziwa ngokwezifiso kweNkqubo epheleleyo

| Igama lemveliso | Umatshini wokuWelding weLaser weRobhothiMLA-W-A01 |

| Ubude bamaza | 1070+/-10 nm |

| Amandla eLaser | 1000W 1500W 2000W 3000W |

| Ukulungiswa kwamandla | 10-100% |

| Ubude beFayibha | Umgangatho we-10m okanye Chaza |

| Iindlela zokuSebenza | CW/Pulse |

| Uluhlu lwesantya | 0-120 mm |

| Ukutyeba kweWeld | 0.5-6 mm |

| Imfuneko ye-Welding Gap | < 1 mm |

| Ukumodareyitha rhoqo | 20KHZ |

| Vula/cima Ixesha | 20 Thina |

| Ubushushu bokusebenza | 15-35 ℃ |

| Ukunikezwa Amandla | 220V/50HZ/30A |

| Iindlela zokuphola | Amanzi Apholileyo Angaphakathi |

| Ubungakanani bomatshini | 990*540*1030 mm |

KULULA UKUSEBENZA

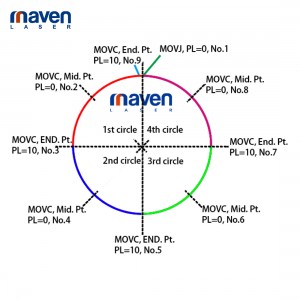

Isilawuli sokusetyenziswa esinobuhlobo kwintsebenziswano elula kunye nomyalelo wokusetyenzwa kwefiber laser welding

ULAWULO INTERGRATION

Ukudityaniswa kwekhabhinethi yolawulo kukulawula umsebenzi wokutyisa ucingo. Kwaye amandla e-laser anokuphakama kwaye awe ngokucothayo ukunqanda ukutshisa ngaphezulu. Ukunyuka okucothayo kunye nokuwa kunenzuzo ngakumbi kwi-welding yepleyiti encinci. Xa i-manipulator igqiba, ngokuqhelekileyo kulula ukuyidibanisa ngepleyiti.

LASE INTERGRATUION

Ukongeza ukulungelelanisa iiparamitha ze-welding kwinkqubo ye-laser. Ikwanayo nemisebenzi yokukhanya kwesimo somgangatho wenkqubo nganye, utshintsho lwamanzi ombane, kunye nesikhumbuzi esizenzekelayo ukukhusela i-lens.

UKUHLANGANISWA KWENTLO

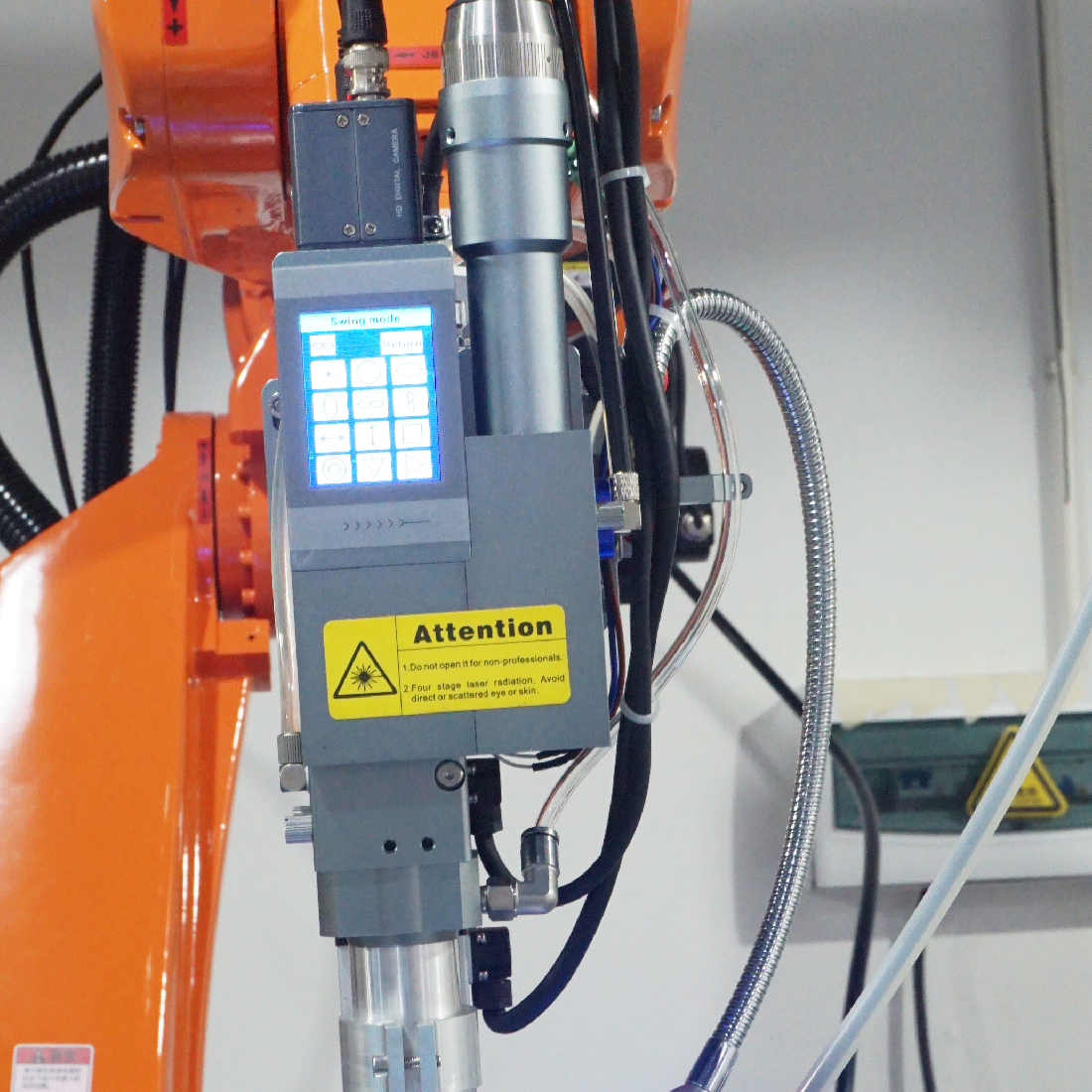

Intloko ye-welding edibeneyo, i-CCD entloko, amandla ahlengahlengiswayo, ukugxila kwe-auto, ukusebenza kakuhle.

KULULA UKUSEBENZA

Amaqhosha ependant yokufundisa alula kwaye kulula ukuwaqonda, kwaye inkqubo yokufundisa inokufundwa kwaye isetyenziswe ngokukhawuleza. Ukuba umsebenzi awulunganga, umatshini uyayeka ngokuzenzekelayo ukuphepha umngcipheko womonakalo wesixhobo.

SEBENZA NGEMPAHLA

Yakuba icwangcisiwe, inokusetyenziswa ngalo lonke ixesha. IMavenLaser Robot Arm ixhasa iiyure ezingama-24 zomsebenzi oqhubekayo ngokuchaneka okuphezulu kunye nesantya esiphezulu. Ukusebenza okuzenzekelayo ngokupheleleyo, i-robot inokugqiba umthwalo womsebenzi wabantu abangaphezu kwe-2-3 ngosuku.

IXABISO ELIPHANTSI

Utyalo-mali lwexesha elinye, iinzuzo zexesha elide. Ubomi benkonzo yerobhothi ye-MavenLaser ziiyure ezingama-80,000, ezilingana neminyaka engaphezu kwe-9 yomsebenzi ongaphazamisekiyo weeyure ezingama-24. Igcina kakhulu iindleko zabasebenzi kunye neendleko zolawulo lwabasebenzi, kwaye isombulule iingxaki ezinjengobunzima ekufuneni abantu.

IKHUSELEKILEYO KWAYE INENEMBEKILEYO

Ingalo yerobhothi yeMavenLaser ixhotyiswe ngamanyathelo okhuseleko lwefotoeletric. Xa izinto zangaphandle zingena kwindawo yokusebenza, inokuthi i-alamu ngokuzenzekelayo kwaye imise umsebenzi ukuphepha ngengozi kumsebenzi.

AMANDLA AKHUSELEKILEYO NOXOLO

Uyilo lomgca wesixhobo somatshini weMavenLaser lulula kwaye lucocekile luncinci, akukho ngxolo, ingalo yerobhothi ekhanyayo kunye neyomeleleyo, ukusetyenziswa kwamandla aphantsi, i-saxing yamandla kunye nokukhuselwa kwendalo.

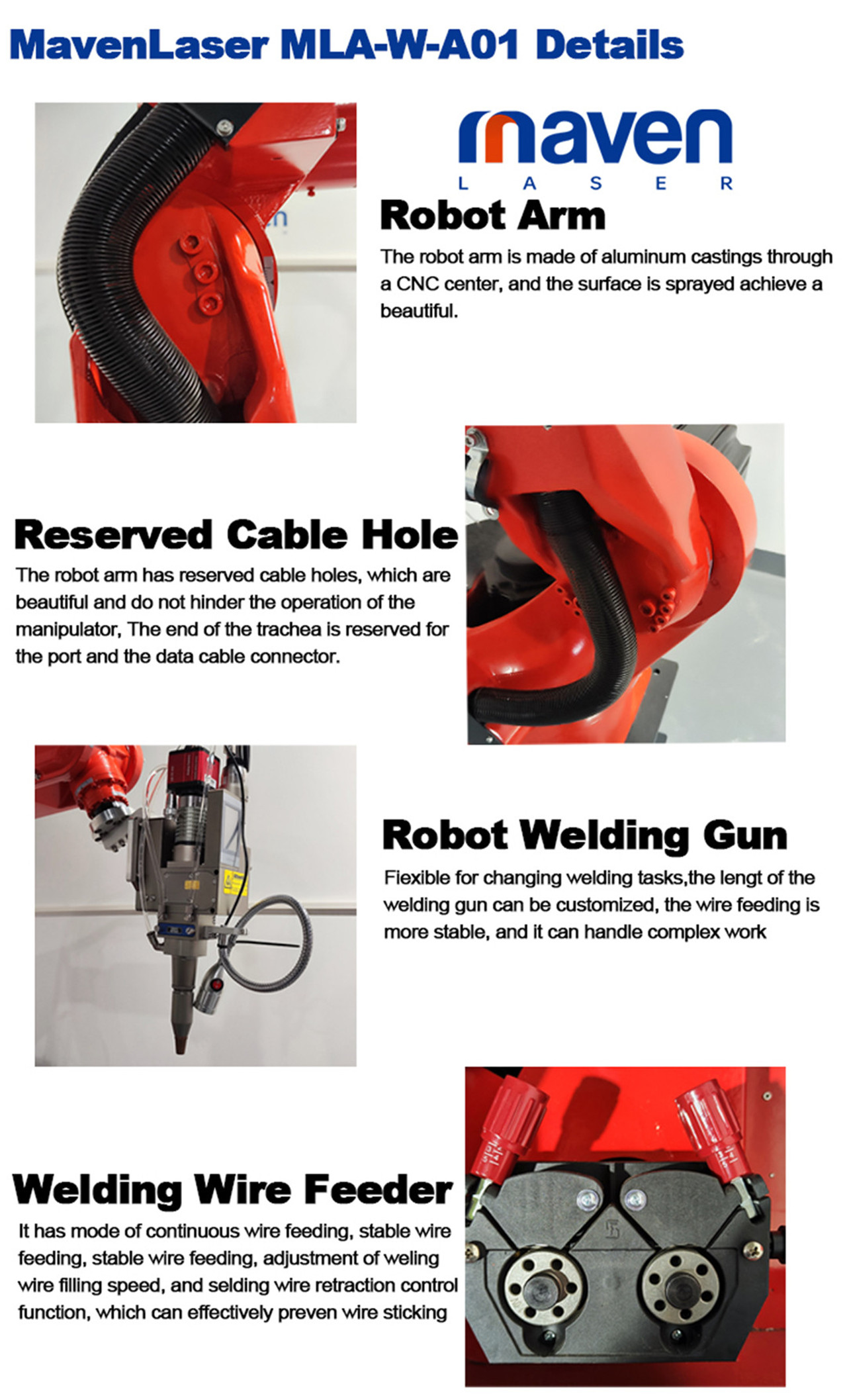

Ingalo yeRobhothi

Ingalo yerobhothi yenziwe nge-aluminium castings ngokusebenzisa iziko le-CNC, kwaye umphezulu utshizwe uzuze ubuhle.

Umngxuma weCable ogciniweyo

Ingalo yerobhothi igcine imingxuma yentambo, ezintle kwaye i-nit ithintela ukusebenza kwe-manipulator, isiphelo se-trachea sigcinelwe i-port kunye ne-data cable connector.

Robot Welding Gun

I-Flexible yokutshintsha imisebenzi ye-welding, ubude bompu we-welding bungenziwa ngokwezifiso, ukutya kweengcingo kuzinzile, kwaye kunokusingatha umsebenzi onzima.

Welding wire Feeder

Inemowudi yesondlo esiqhubekayo socingo, ukutyisa ucingo oluzinzileyo, ukutya okuzinzile, ukulungiswa kwesantya sokuzalisa ucingo, kunye nokuthengisa umsebenzi wokulawula ukurhoxiswa kwentambo, enokuthintela ngokufanelekileyo ukubamba ucingo.

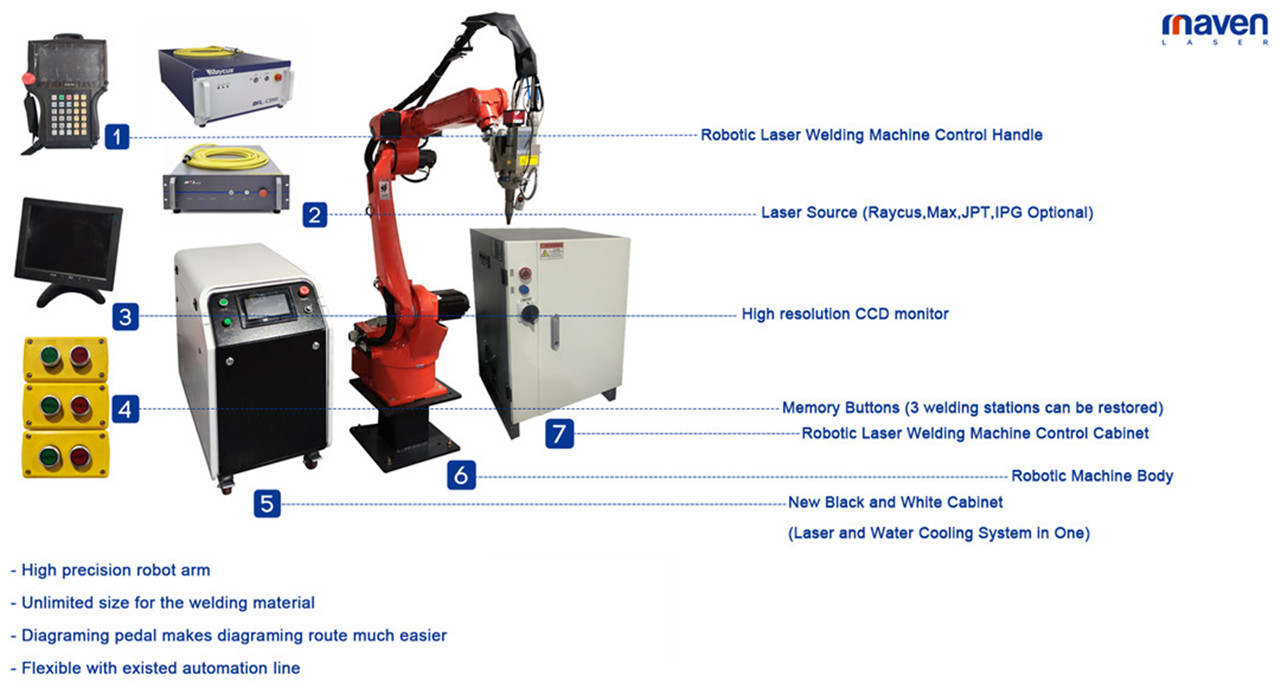

● Umthombo weLaser(Raycus,Max,JPT,IPG Optional)

● Imonitha yeCCD enesisombululo esiphezulu

● Amaqhosha eMemori (3 izitishi zokuwelda zinokubuyiswa)

● IKhabhinethi eNtsha eMnyama neMhlophe (Inkqubo yokuPholisa iLaser kunye naManzi kwiNye)

● I-Robotic Machine Body

● IKhabhinethi yoLawulo lwe-Robotic Laser Welding Machine

● Ingalo yerobhothi echanekileyo

● Ubungakanani obungenamkhawulo wezinto ezidibanisayo

● Umzobo wepedali wenza indlela yokuzoba lula kakhulu

● Ibhetyebhetye ngomgca ozenzekelayo okhoyo

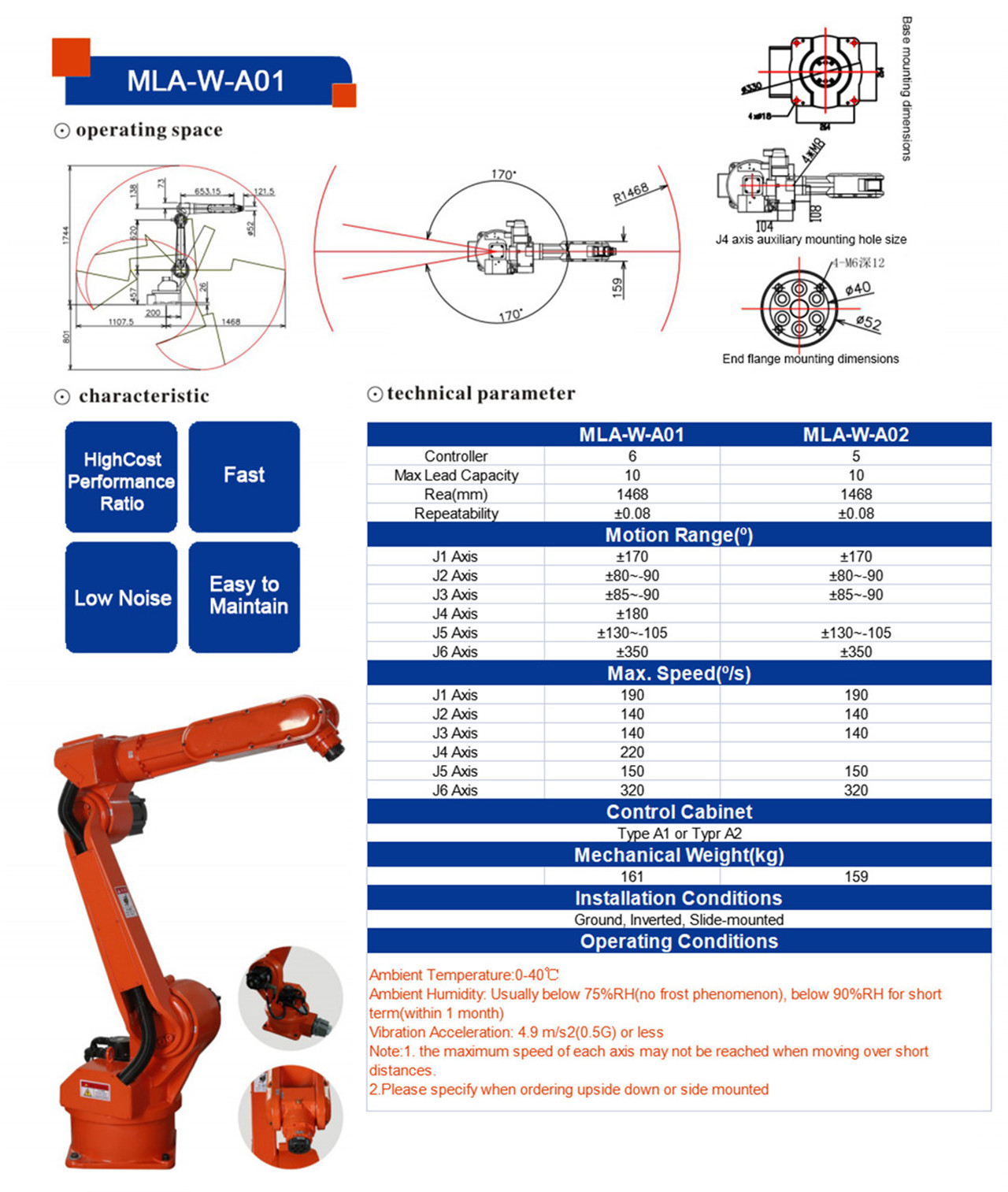

| MLA-W-A01 | I-MLA-WA02 | |

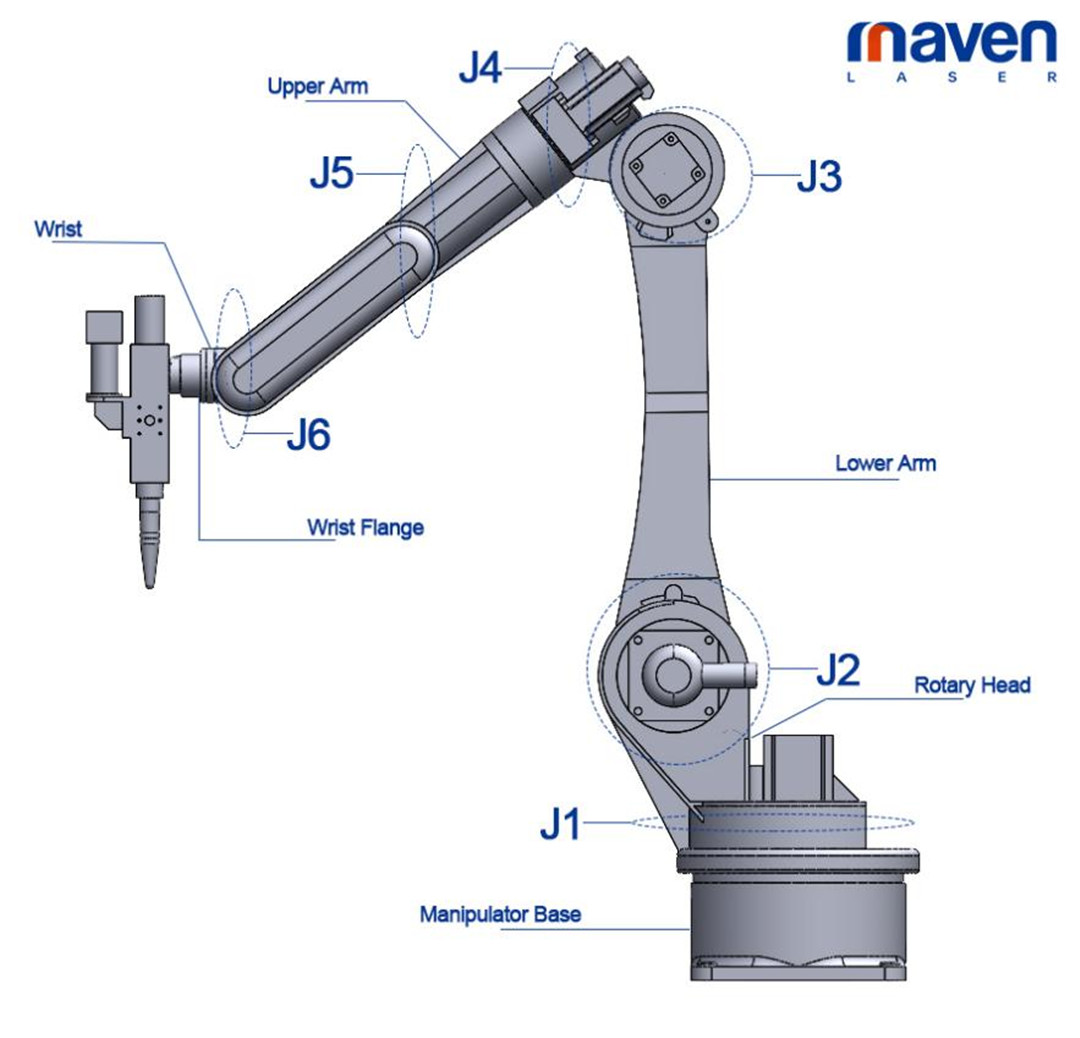

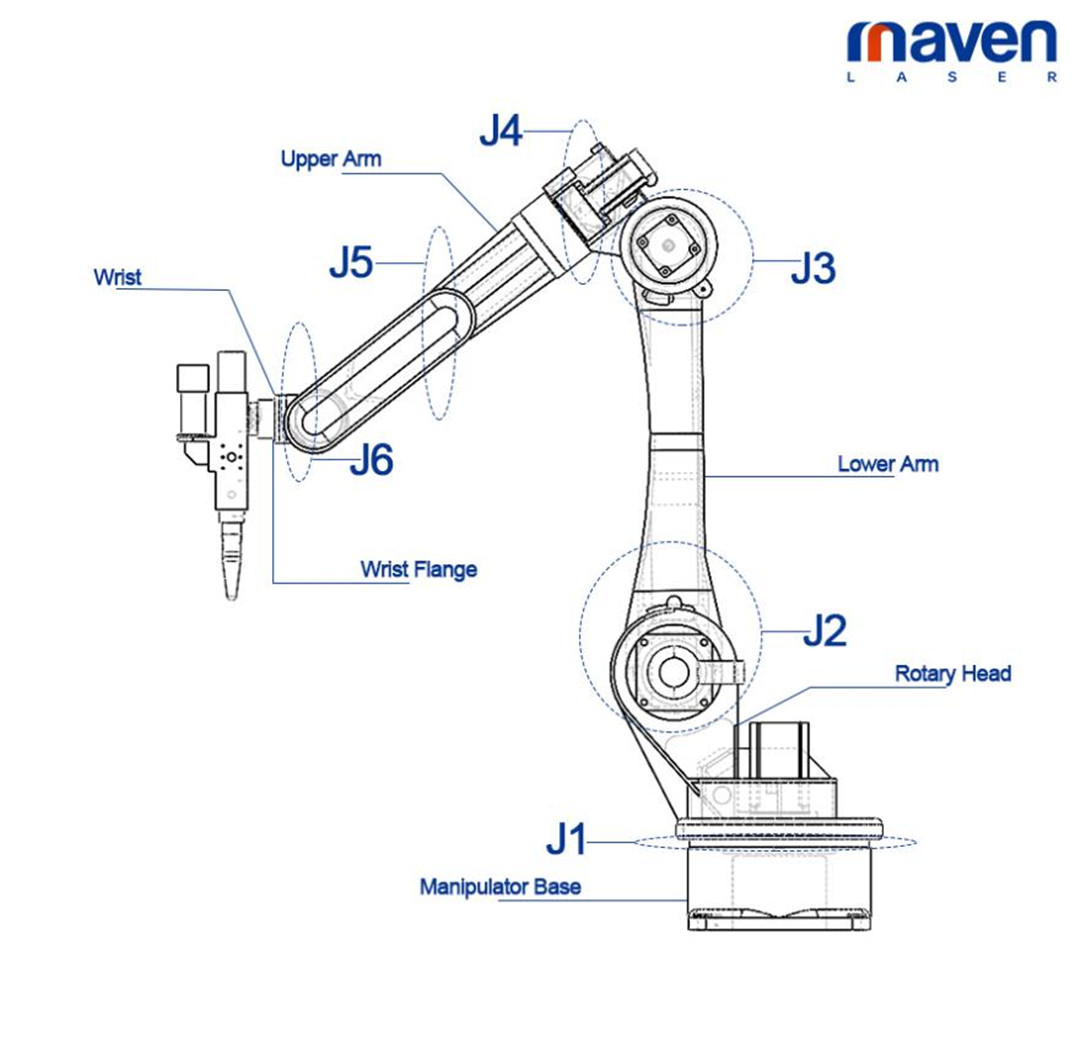

| Umlawuli | 6 | 5 |

| Ubukhulu beNkokheli yeZakhono | 10 | 10 |

| NONE | 1468 | 1468 |

| Ukuphindaphinda | ±0.08 | ±0.08 |

| Uluhlu lwentshukumo(°) | ||

| Umgca we-J1 | ±170 | ±170 |

| Umgca we-J2 | ±80~-90 | ±80~-90 |

| I-J3 Axis | ±85~-90 | ±85~-90 |

| Umgca we-J4 | ±180 |

|

| Umgca we-J5 | ±130~-105 | ±130~-105 |

| Umgca we-J6 | ±350 | ±350 |

| Max. Isantya(°/s) | ||

| Umgca we-J1 | 190 | 190 |

| Umgca we-J2 | 140 | 140 |

| I-J3 Axis | 140 | 140 |

| Umgca we-J4 | 220 |

|

| Umgca we-J5 | 150 | 150 |

| Umgca we-J6 | 320 | 320 |

| IKhabhinethi yoLawulo | ||

| Uhlobo A1 okanye Uhlobo A2 | ||

| Ubunzima boomatshini(kg) | ||

|

| 161 | 159 |

| Imiqathango yoFakelo | ||

| Umhlaba, uGuquliwe, unyuswe kwisilayidi | ||

| Iimeko zokusebenza | ||

Ubushushu be-Ambient:0-40℃

Ukufuma kwe-Ambient: Ngesiqhelo ngaphantsi kwe-75%RH(akukho qabaka), ngaphantsi kwe-90%RH okwexeshana(kwinyanga enye)

Ukukhawulezisa ukungcangcazela::4.9 m/s2(0.5G) okanye ngaphantsi

Qaphela: 1.esona santya siphezulu se-axis nganye ayinakufikelelwa xa ushukuma kumgama omfutshane.

2.Nceda ucacise xa uodola ujonge phantsi okanye unyuswe ecaleni

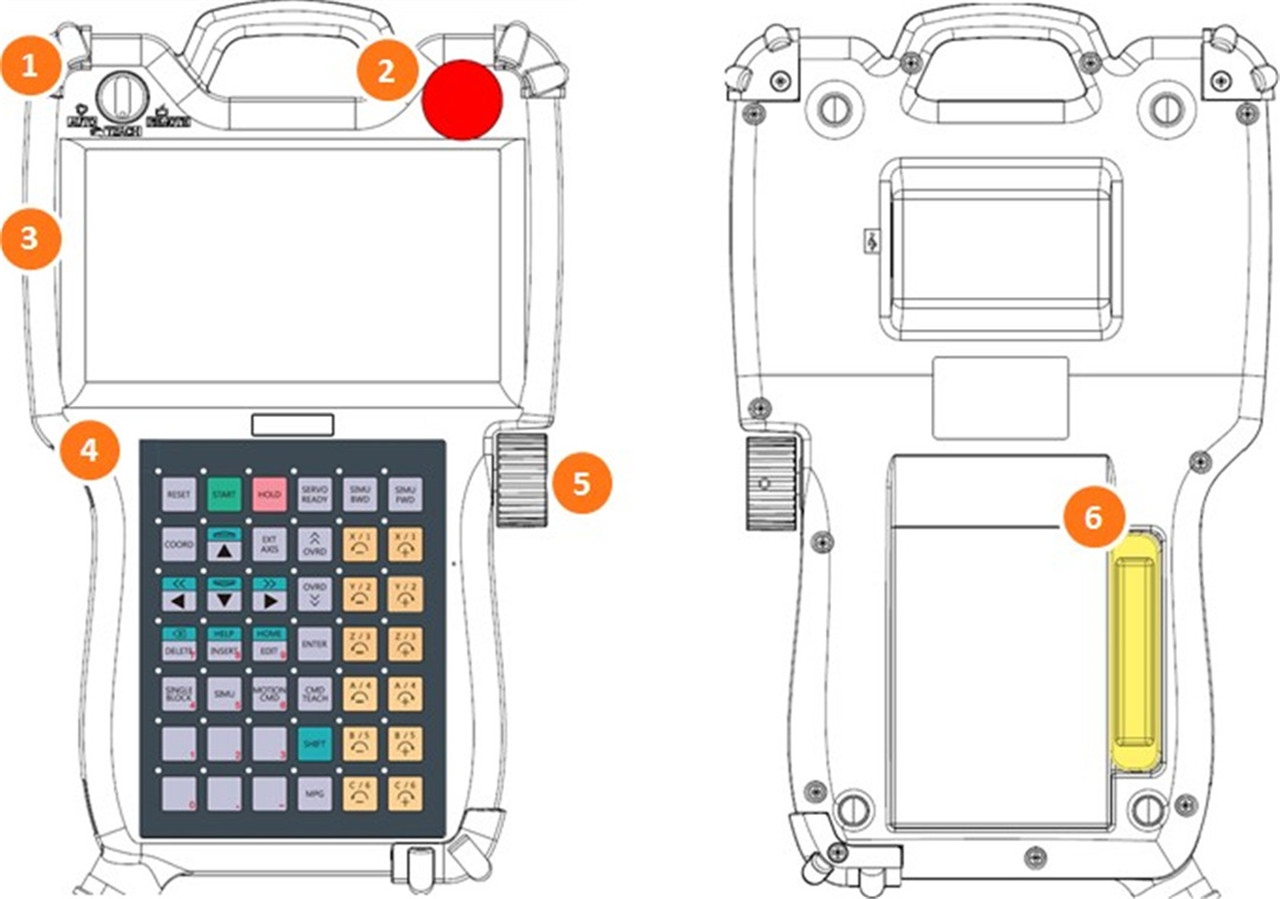

1. Ukutshintsha iMowudi

2. Ukuyeka ngokuNgxamisekileyo

3. Isikrini sokubonisa

4. Izitshixo zePhysical

5. MPG (Manuel Pulse Generator)

6. Ukuvula isixhobo