NgoJanuwari 2023, inani leenkampani zaseTshayina zibhengeze izicwangciso zokwandisa amandla kunye neebhetri zokugcina amandla, kunye nesixamali sotyalo-mali esisondela kwi-100 yeebhiliyoni zeeyuan kunye nomthamo wemveliso odibeneyo we-269 GWh, ukugqithisa imveliso edibeneyo kwisiqingatha sokuqala sonyaka ophelileyo (206.4 GWh ) kwaye phantse ukugubungela imfuno yebhetri yamandla yasekhaya kunyaka ophelileyo (294.6 GWh)

| Ishishini | Imali yotyalo-mali (ibhiliyoni) | Umthamo wemveliso(GWh) |

| BYD | 10 (Kuqikelelwa) | 35 |

| IBHETRI KA-Eva | 20.8 | 80 |

| Ganfeng Lithium | 15 | 34 |

| IBHATHA YEBAK | 13 | 30 |

| Farasis Amandla | 10 | 30 |

| Iqela leShenghong | 30.6 | 60 |

| Iyonke | 99.4 | 269 |

Umthombo weDatha: Iindaba ze-China Automotive, idatha yenethiwekhi yoluntu

Ngexesha lokuveliswa kweebhetri zamandla, ukuzinza komgangatho we-shell shell welding kuya kuchaphazela ukuhambelana kunye nokhuseleko lwenkqubo yokuhlanganisa ibhetri. Ngaphakathi kwiqokobhe lebhetri yamandla iqulathe ikakhulu i-electrolyte ephilayo, i-diaphragm ekhethekileyo, kwaye isigqubuthelo siqulethe ivalve yobungqina bokudubula, ipali yepali, ikepusi yokhuseleko, umngxuma wokutofa ulwelo, njl. njl. kunye nomgangatho wayo we-welding uchaphazela ngokuthe ngqo iqondo lokutywinwa kwebhetri, kwaye i-welding engalunganga iya kukhokelela ekuvuzeni kwebhetri, i-lithium precipitation, kunye nokubonakala kwebhetri akukho mgangatho.

▲Iqokobhe elilukhuni le-lithium ibhetri ye-solder

01 Iingxaki ze-welding eziqhelekileyo zomthungo

I-1- inkangeleko embi: i-welding bias, amehlo entlabathi, isampuli ye-tilt

2- Amandla angonelanga kunye nokutywinwa: ubunzulu obunganelanga bokudibanisa, iintanda, imingxunya emikhulu yomoya ekhokelela ekuvuzeni kwebhetri.

02 Uhlalutyo lwenkqubo yeengxaki ze-welding seam

Ngokohlalutyo lwempazamo ye-FTA, ingxaki yokungaphumeleli kwe-welding ishwankathelwa ikakhulu njengembonakalo embi kunye neengxaki zamandla e-welding. Imbonakalo embi izinto: izixhobo welding yeCCD yokuskena inkqubela, uhlobo lwegesi ekhuselayo kunye nesantya sokuqukuqela, ukucoceka kwesampulu ye-welding, isampula yokuchaneka komatshini kunye nendlela. Amandla e-welding kunye nokutywinwa kwezinto: izinto eziluhlaza ngokuchanekileyo, ukubunjwa kwe-aluminium, impembelelo yeeparitha zenkqubo.

| Ukuhlelwa | Imibuzo | Ukwahlulwa kweNkqubo engunobangela | Izizathu ezithile |

|

Imbonakalo | Ukuwelda inxalenye | Indlela yokuwelda Ukuchongwa kunye nokubekwa | Inkqubo yokubeka umbono weCCD ayinakukwazi ukuchonga ngokuchanekileyo iimpawu zesampulu, okubangela ukuba i-welding trajectories itenxile, ukuvezwa okunganeleyo komthombo wokukhanya oncedisayo kwisampuli, kunye nobunzima obuninzi ekumiseni ifoto. |

| Umngxuma womoya weTrakoma | Izinto ngokwazo kunye nokusingqongileyo welding | Ukubunjwa kwezinto ze-aluminium iqokobhe, ukusetwa okungafanelekanga kohlobo lwegesi ekhuselayo kunye nesantya sokuhamba, ukuhambelana okungafanelekanga kwendlela yokudibanisa i-welding kunye ne-gap ye-weld yesigqubuthelo kunye negobolondo, ukucoceka okwaneleyo kwe-welding yecala okanye indawo ye-welding ephezulu. | |

| Ukungalingani kwesampulu | Isampula yokuchaneka kwendibano | Isigqubuthelo kunye neqokobhe phezulu welding indlela weld umsantsa ilingana ngokungafanelekanga, inkqubo welding uxinzelelo ukuqokelelana. | |

| Amandla e-welding | Ukuvuza kwebhetri | Impazamo yobungakanani besampulu kunye nefuthe leeparamitha ze-welding | Isigqubuthelo kunye nobukhulu beqokobhe olulungeleyo aluzinzile, kwaye iiparamitha zenkqubo azimiselwanga ngokuchanekileyo. |

03 Indima yerhasi ekhuselayo

Igesi ekhuselayo kwinkqubo ye-laser welding inokuthintela i-oxidation yobuso besinyithi, ikhusele i-lens, ivuthe i-plasma, idinga ukulawula indlela yokuhamba komoya, uxinzelelo, izinga lokuhamba. Irhasi ekhuselayo yenza isiphithiphithi, i-weld iya kuba ne-porosity, i-weld seam engalinganiyo kunye nezinye iingxaki.

04 Iimpawu ezahlukeneyo zerhasi

Iintlobo zeegesi ezikhuselayo kwi-laser welding ziquka i-helium, i-argon kunye ne-nitrogen

I-Helium: Iqondo eliphezulu le-ionization, i-laser inokudlula, onke amandla e-beam afikelela kumphezulu we-workpiece, akukho lula ukuvelisa i-porosity, kodwa kubiza kakhulu.

I-Argon: ixabiso eliphantsi kune-helium, kodwa lichaphazeleka kwi-ionization ye-plasma ephezulu, nangona umphumo wokukhusela ungcono, kodwa uya kuyikhusela inxalenye ye-laser processing yamandla, ukunciphisa amandla e-laser, ukusetyenziswa kwe-helium welding surface imbonakalo egudileyo.

I-nitrogen: ixabiso eliphantsi, i-ionization encinci, ukudumba kwe-welding kuya kusabela kunye nezinto ezithile ze-aluminium alloy ukuvelisa iikhompawundi ezingazinzanga, ezichaphazela amandla okuwelda.

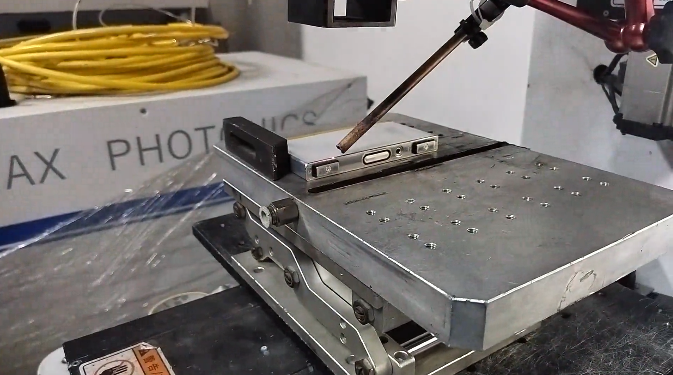

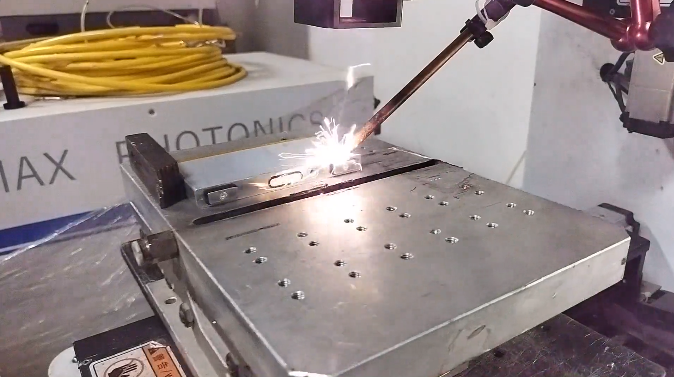

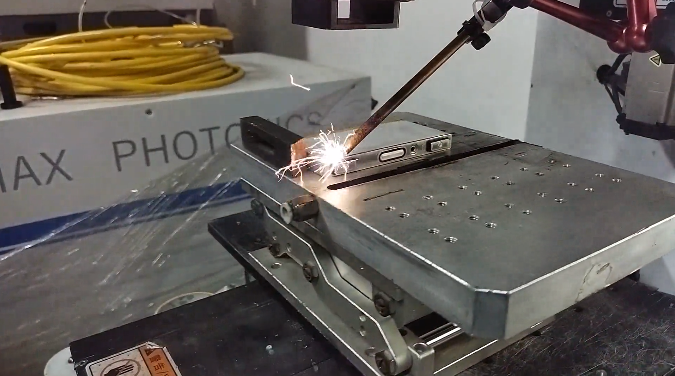

05 Uhlalutyo lwempembelelo yeemeko ze-welding ezahlukeneyo

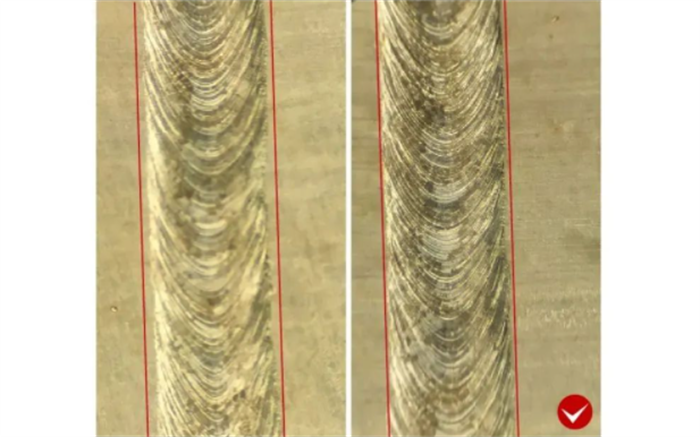

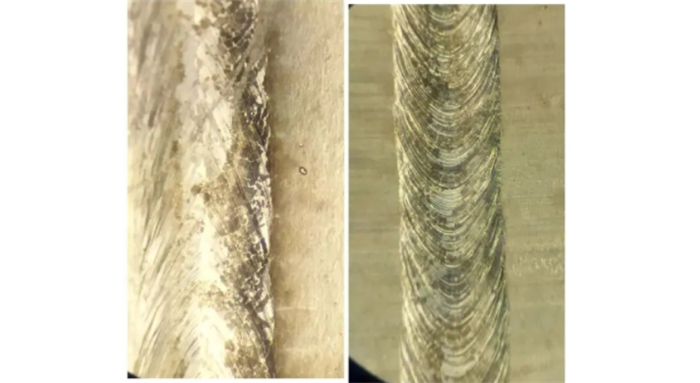

I-Welding nge-nitrogen kunye ne-argon njengegesi ekhuselayo, xa usebenzisa i-nitrogen njengegesi yokukhusela, ukuhambelana kobubanzi be-weld akubi kakuhle, usebenzisa i-argon njengegesi yokukhusela, ukuvulwa kwe-weld kuyagudiswa, ipateni yesikali seentlanzi iphuculwe ngokulinganayo, kwaye imbonakalo ingcono kunokusebenzisa. iimveliso ze-nitrogen welding. (Njengoko kubonisiwe kulo mfanekiso ungezantsi)

▲Ifuthe elahlukileyo lokukhusela irhasi yentsimbi (ukuhambelana kobubanzi bomthungo okwahlukileyo)

Laser amandla kwi impembelelo welding, usebenzisa isantya welding efanayo kunye nerhasi ekhuselayo, iphezulu imveliso yamandla yokwenene, ngokukhawuleza izinto weld inokunyibilika kunye nomphunga, ukunyibilika ukunyibilika fluidity pool, ipateni isikali intlanzi umphezulu iyunifomu ngakumbi, umthungo we weld uba tyaba ngakumbi. (Njengoko kubonisiwe kulo mfanekiso ungezantsi)

▲ Impembelelo ye-welding yamandla eyahlukileyo (ukufana komphezulu owahlukileyo)

Isishwankathelo

1. ukuya kwindawo yokugcina izixhobo zokutywina ze-laser, i-CCD yokuskena indawo kunye neeparamitha ze-welding zinempembelelo kwinkangeleko yobubi kwingxaki ye-welding inxalenye.

2. Uhlobo lwegesi olukhuselayo kunye nemimiselo yeparameter inokuphucula ukuhambelana okufanayo kwe-weld, ukuqinisekisa ukucoceka kwendawo ye-welding, ukunciphisa ukungeniswa kwezinto ezingcolileyo zangaphandle, kunokunciphisa i-welding slag eyenziwa yi-trachoma porosity.

3. Mechanical fit kwi gap kufanelekile ngaphezu kokuphazamiseka, inkqubo ukuwelda intsimi kwindawo yokuqala ukuwelda kwaye ngokuqhubekayo indlela welding, kunokusombulula ubukhulu becala umsantsa xa iingxaki ukuwelda uzinzo.

I-Maven Laser yinkampani egxile kwishishini le-laser, eyasekwa ngo-2008, ngoku ineminyaka emi-5 yamava oshishino kwintsimi ye-laser welding, ikhethekileyo ekukhetheni izisombululo ze-laser ezifanelekileyo kunye noomatshini bokuwelda belaser kuwe. NgoJanuwari, sasungula umatshini wethu we-laser we-air-cooled handheld welding, ngoku okwixesha elikhethekileyo lokunyusa, uthenge iiyunithi ezi-5, ixabiso leyunithi enye liphantsi njenge-$ 4500, thenga iiyunithi ezili-10, ixabiso leyunithi enye. isezantsi njenge $4200. I-welding ye-air-cooled handheld incinci, ifanelekile kwi-welding yangaphandle, kunye ne-Maven's air-cooled laser welding machine isombulula ingxaki yangoku yokutshatyalaliswa kobushushu kwaye inokusebenza ixesha elide ngaphandle kokuphazamiseka. Wamkelekile kumbuzo wakho! SiyiMaven Laser, iqabane lakho lobuchwephesha belaser.

Ixesha lokuposa: Mar-03-2023