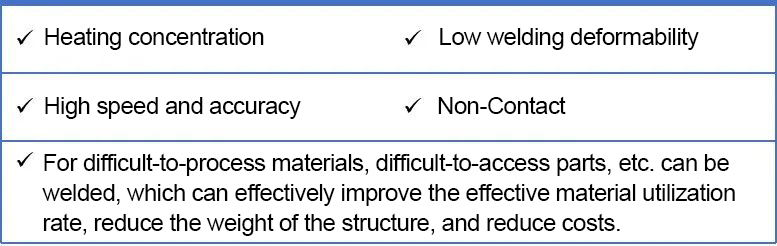

Itekhnoloji yokujoyina i-laser, okanye itekhnoloji ye-laser welding, isebenzisa i-laser beam yamandla aphezulu ukugxila kunye nokulawula ukukhanya komphezulu wezinto eziphathekayo, kwaye umphezulu wezinto eziphathekayo ufunxa amandla e-laser kwaye uyiguqule ibe amandla obushushu, okwenza ukuba izinto zifudumale kwaye zinyibilike. , ilandelwa kukupholisa kunye nokuqinisa ukufezekisa ukudibanisa kwezinto ezilinganayo okanye ezingafaniyo. Inkqubo ye-laser welding ifuna ukuxinana kwamandla e-laser ye-104ukuya ku108W/cm2. Xa kuthelekiswa neendlela zemveli zokuwelda, ukuwelda ngelaser kunezi nzuzo zilandelayo.

Itekhnoloji yokujoyina i-laser, okanye itekhnoloji ye-laser welding, isebenzisa i-laser beam yamandla aphezulu ukugxila kunye nokulawula ukukhanya komphezulu wezinto eziphathekayo, kwaye umphezulu wezinto eziphathekayo ufunxa amandla e-laser kwaye uyiguqule ibe amandla obushushu, okwenza ukuba izinto zifudumale kwaye zinyibilike. , ilandelwa kukupholisa kunye nokuqinisa ukufezekisa ukudibanisa kwezinto ezilinganayo okanye ezingafaniyo. Inkqubo ye-laser welding ifuna ukuxinana kwamandla e-laser ye-104ukuya ku108W/cm2. Xa kuthelekiswa neendlela zemveli zokuwelda, ukuwelda ngelaser kunezi nzuzo zilandelayo.

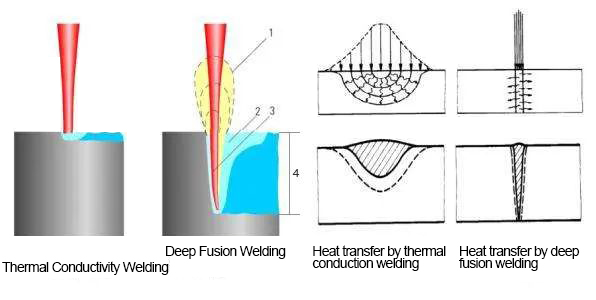

Ilifu eli-1-plasma, izinto ezinyibilikayo ezi-2, umngxuma wesitshixo esi-3, ubunzulu obu-4 bokudityaniswa

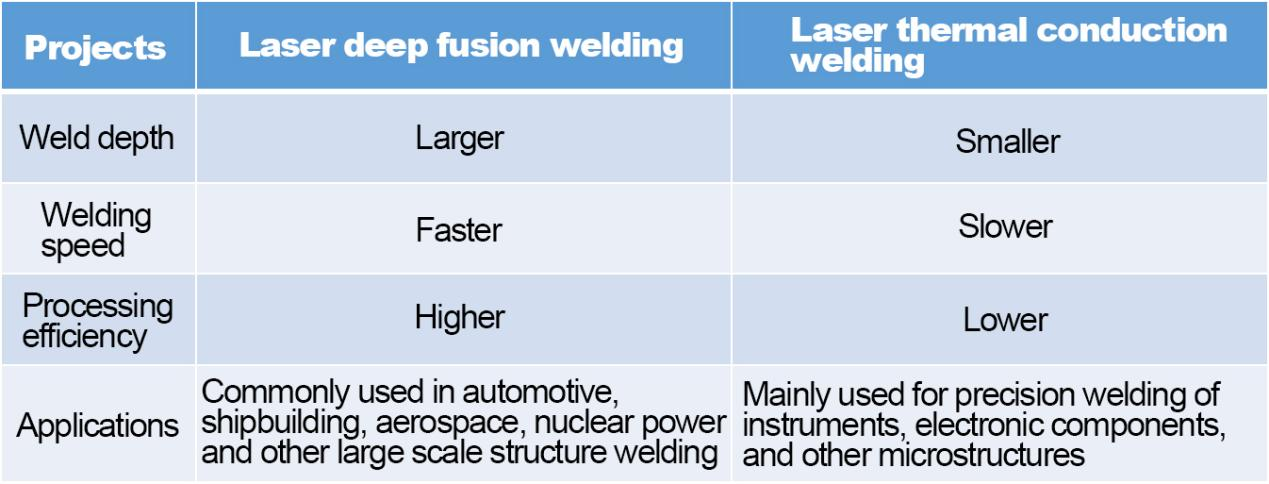

Ngenxa yobukho be-keyhole, i-laser beam, emva kokukhanyisa ngaphakathi kwi-keyhole, iya kwandisa ukuxutywa kwe-laser ngezinto eziphathekayo kwaye ikhuthaze ukubunjwa kwechibi elinyibilikisiweyo emva kokusasazeka kunye nezinye iziphumo, iindlela ezimbini ze-welding zifaniswa. ngoku Landelayo.

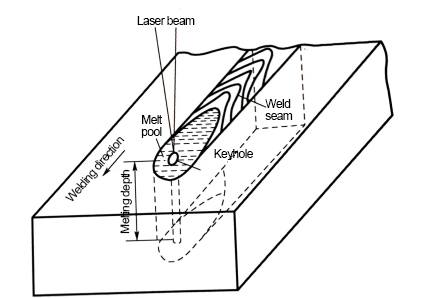

Lo mzobo ungasentla unika inkqubo ye-laser welding yesixhobo esifanayo kunye nomthombo wokukhanya ofanayo, indlela yokuguqula amandla yenziwa kuphela ngomngxuma wesitshixo, umngxuma wesitshixo kunye nentsimbi etyhidiweyo kufutshane nodonga lomngxuma uhamba kunye nokuhamba phambili kwe-laser beam, isinyithi esinyibilikisiweyo sisusa umngxuma wesitshixo ukusuka emoyeni oshiywe ngasemva ukuze ugcwalise kwaye emva kokujiya, wenze i-weld seam.

Ukuba izinto ezidityanisiweyo yintsimbi engafaniyo, ubukho bomahluko kwiipropati zokushisa kuya kuba nefuthe elikhulu kwinkqubo ye-welding, njengomahluko kwiindawo zokunyibilika, ukuqhutyelwa kwe-thermal, umthamo wobushushu obuthile, kunye nokwandiswa kwee-coefficients zezinto ezahlukeneyo, okubangelwa kuxinzelelo lwe-welding, i-welding deformation, kunye nokutshintsha kweemeko ze-crystallization yentsimbi edibeneyo edibeneyo, ebangela ukuhla kweempawu zomatshini we-weld.

Ke ngoko, ngokweempawu ezahlukeneyo zendawo yokuwelda, inkqubo yokuwelda iphuhlise i-laser filler welding, i-laser brazing, i-laser-beam welding, i-laser composite welding, njl.

Laser Wire Ukuzalisa Welding

Kwinkqubo ye-laser welding ye-aluminium, i-titanium kunye ne-alloys yobhedu, ngenxa yokunciphisa okuphantsi kokukhanya kwe-laser (<10%) kwezi zinto, ifoto eyenziwe ngeplasma inokhuselo oluthile lokukhanya kwe-laser, ngoko kulula ukwenza i-spatter kwaye kukhokelela ekuveliseni iziphene ezifana ne-porosity kunye neentanda. Ukongeza, umgangatho we-welding uyachaphazeleka xa umsantsa phakathi kwezinto zokusebenza umkhulu kunobubanzi bebala ngexesha lokutshiza kwepleyiti ebhityileyo.

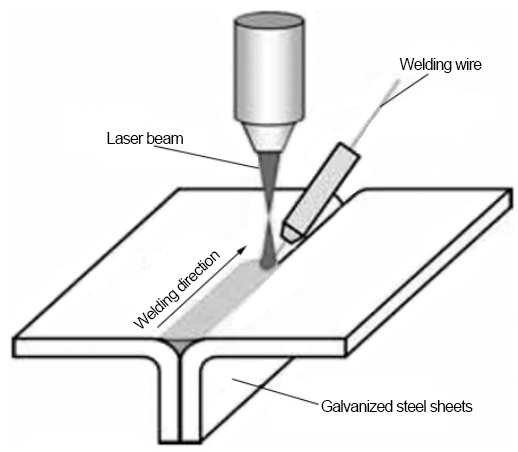

Ekusombululeni ezi ngxaki zingentla, umphumo ongcono we-welding unokufumaneka ngokusebenzisa indlela yezinto zokuzalisa. Ukuzaliswa kunokuba yingcingo okanye umgubo, okanye indlela yokugcwalisa kwangaphambili ingasetyenziswa. Ngenxa yendawo encinci ekugxilwe kuyo, i-weld iba mfutshane kwaye inemilo encinci ye-convex kumphezulu emva kokuba kufakwe izinto zokuzalisa.

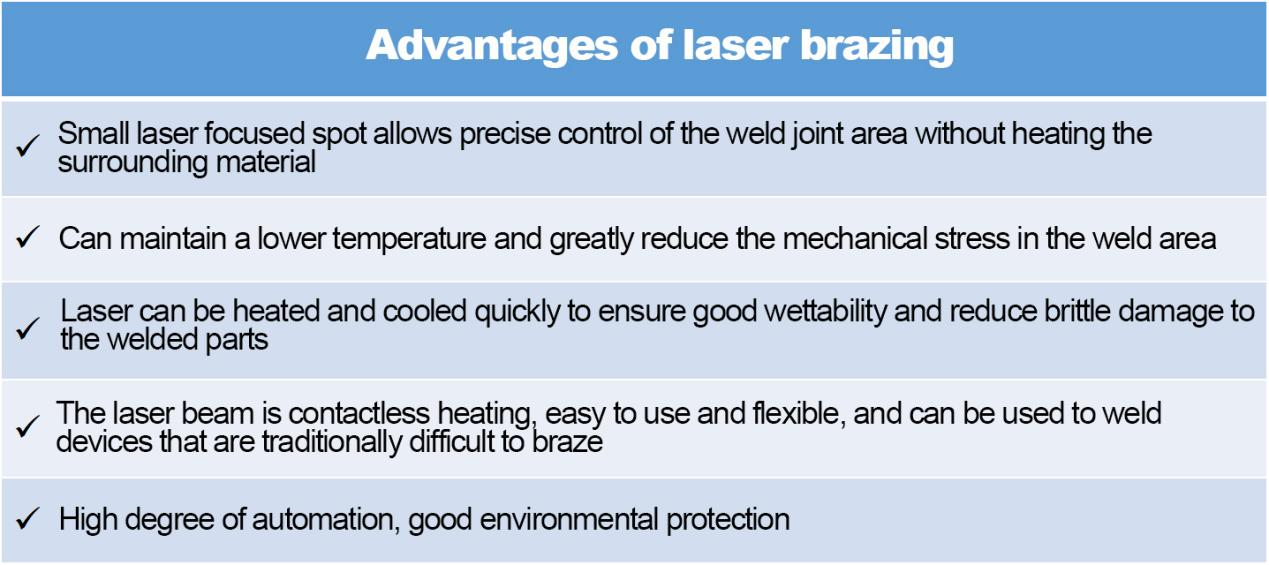

I-Laser Brazing

Ngokungafaniyo ne-fusion welding, enyibilikisa iinxalenye ezimbini ezidityanisiweyo ngaxeshanye, ibrazing yongeza imathiriyeli yokuzalisa enendawo yokunyibilika esezantsi kunesiseko sezinto kwindawo ye-weld, inyibilikisa izinto zokuzalisa ukuzalisa isithuba kwiqondo lobushushu elisezantsi kunonyibilika wesiseko. inqaku kwaye iphezulu kunendawo yokunyibilika yesixhobo sokugcwalisa, kwaye emva koko iyajiya ukwenza i-weld eqinileyo.

I-Brazing ilungele izixhobo ze-microelectronic ezingeva lubushushu, iipleyiti ezibhityileyo, kunye nemathiriyeli yentsimbi eguquguqukayo.

Ngaphezu koko, inokuphinda ihlelwe njenge-soft brazing (<450 °C) kunye ne-hard brazing (>450 ° C) kuxhomekeke kwiqondo lokushisa apho i-brazing ishushu.

I-Dual Beam Laser Welding

I-welding ye-double-beam ivumela ulawulo oluguquguqukayo nolufanelekileyo lwexesha kunye nesikhundla se-laser irradiation, ngaloo ndlela ukulungelelanisa ukuhanjiswa kwamandla.

Isetyenziswa ikakhulu kwi-laser welding ye-aluminiyam kunye ne-magnesium alloys, i-splice kunye ne-lap plate welding kwiimoto, i-laser brazing kunye ne-fusion yelding enzulu.

I-double beam inokufunyanwa ngama-lasers amabini azimeleyo okanye ngokuhlukana kwe-beam kunye ne-beam splitter.

Imiqadi emibini ingaba yindibaniselwano ye-lasers kunye neempawu zesizinda sexesha elihlukeneyo (i-pulsed vs. eqhubekayo), i-wavelengths eyahlukeneyo (i-middle-infrared vs. Wavelengths ebonakalayo) kunye namandla ahlukeneyo, anokukhethwa ngokubhekiselele kwizinto ezicutshungulwayo zangempela.

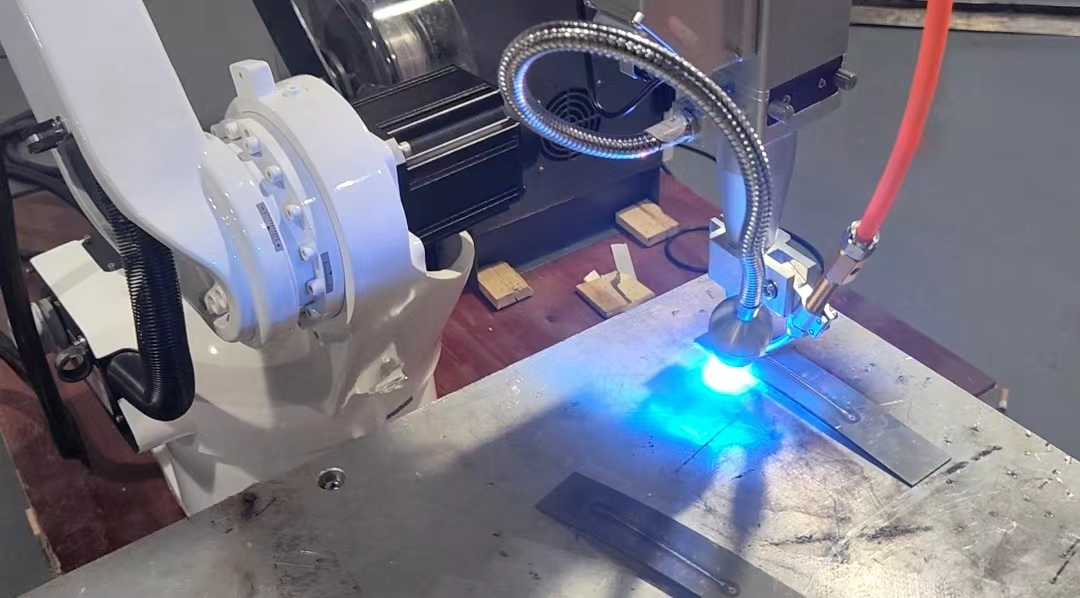

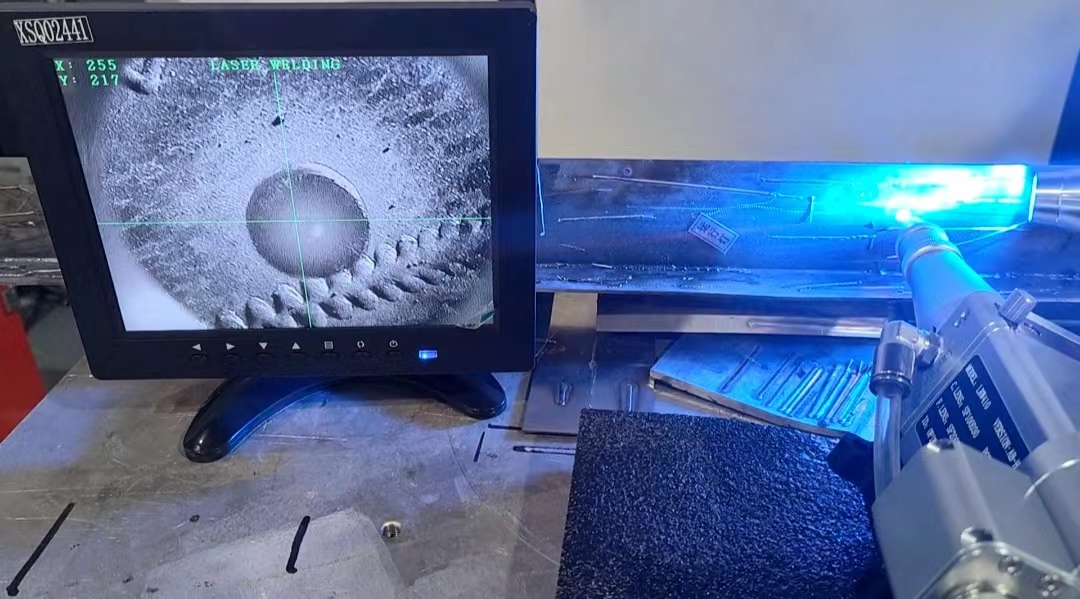

4.Laser Composite Welding

Ngenxa yokusetyenziswa kwe-laser beam njengokuphela komthombo wobushushu, i-laser ye-welding enye yobushushu inezinga eliphantsi lokuguqulwa kwamandla kunye nesantya sokusetyenziswa, isiseko se-weld port interface kulula ukuvelisa ukungahambi kakuhle, kulula ukuvelisa iipores kunye neentanda kunye nezinye iintsilelo, ukuze ucombulule le ngxaki, ungasebenzisa iimpawu zokufudumeza zeminye imithombo yobushushu ukuphucula ukufudumeza kwelaser kwindawo yokusebenza, edla ngokubizwa ngokuba yi-laser composite welding.

Uhlobo oluphambili lwe-laser composite welding yi-welding edibeneyo ye-laser kunye ne-arc yombane, i-1 + 1> i-2 isiphumo silandelayo.

emva kwe-laser beam kufuphi ne-arc esetyenzisiweyo,Ubuninzi be-electron buyancipha kakhulu, ifu yeplasma eyenziwa yi-laser welding ihlanjululwe, leyoinokwenza izinga lokufunxa kwelaser liphuculwe kakhulu, ngelixa i-arc kwi-base material preheating iya kwandisa ngakumbi izinga lokufunxa kwe-laser.

2. Ukusetyenziswa kwamandla aphezulu kwi-arc kunye netotaliukusetyenziswa kwamandla kuya kwandiswa.

I-3, indawo ye-laser ye-welding yesenzo incinci, kulula ukubangela ukungahambi kakuhle kwechweba le-welding, ngelixa isenzo se-thermal ye-arc sikhulu, esinokuthiukunciphisa ukungahambi kakuhle kwe-welding port. Kwangaxeshanye, iumgangatho we-welding kunye nokusebenza kakuhle kwe-arc kuphuculwengenxa yokugxila kunye nempembelelo yesikhokelo se-laser beam kwi-arc.

I-4, i-laser welding kunye nobushushu obuphezulu obuphezulu, indawo enkulu echatshazelwe ngubushushu, ukupholisa ngokukhawuleza kunye nesantya sokuqina, kulula ukwenza iintanda kunye neepores; ngelixa indawo ye-arc echaphazeleke bubushushu incinci, enokunciphisa iqondo lobushushu, ukupholisa, isantya sokuqina,inokunciphisa kwaye isuse ukuveliswa kwee-pores kunye nokuqhekeka.

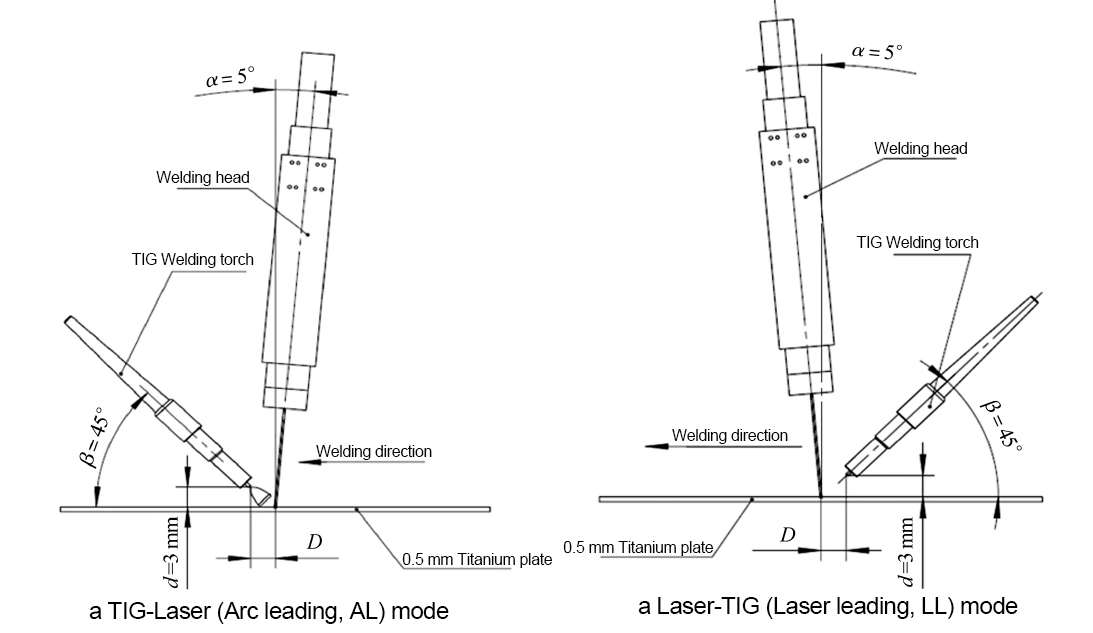

Kukho iindlela ezimbini eziqhelekileyo ze-laser-arc composite welding: i-laser-TIG ye-composite welding (njengoko kuboniswe ngezantsi) kunye ne-laser-MIG composite welding.

Kukho nezinye iindlela zokuwelda ezifana ne-laser kunye ne-plasma arc, i-laser kunye ne-inductive heat source i-welding edibeneyo.

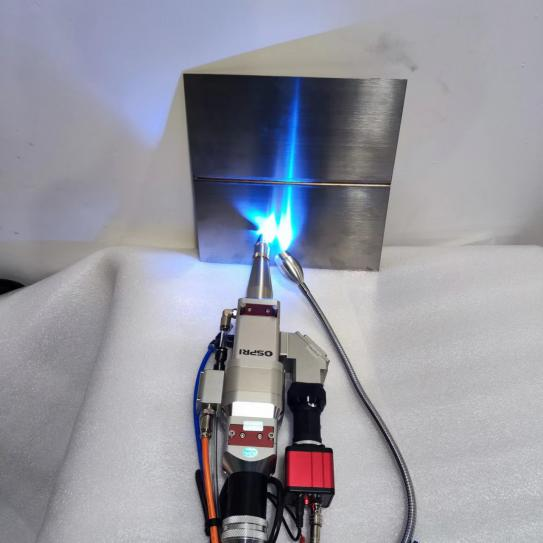

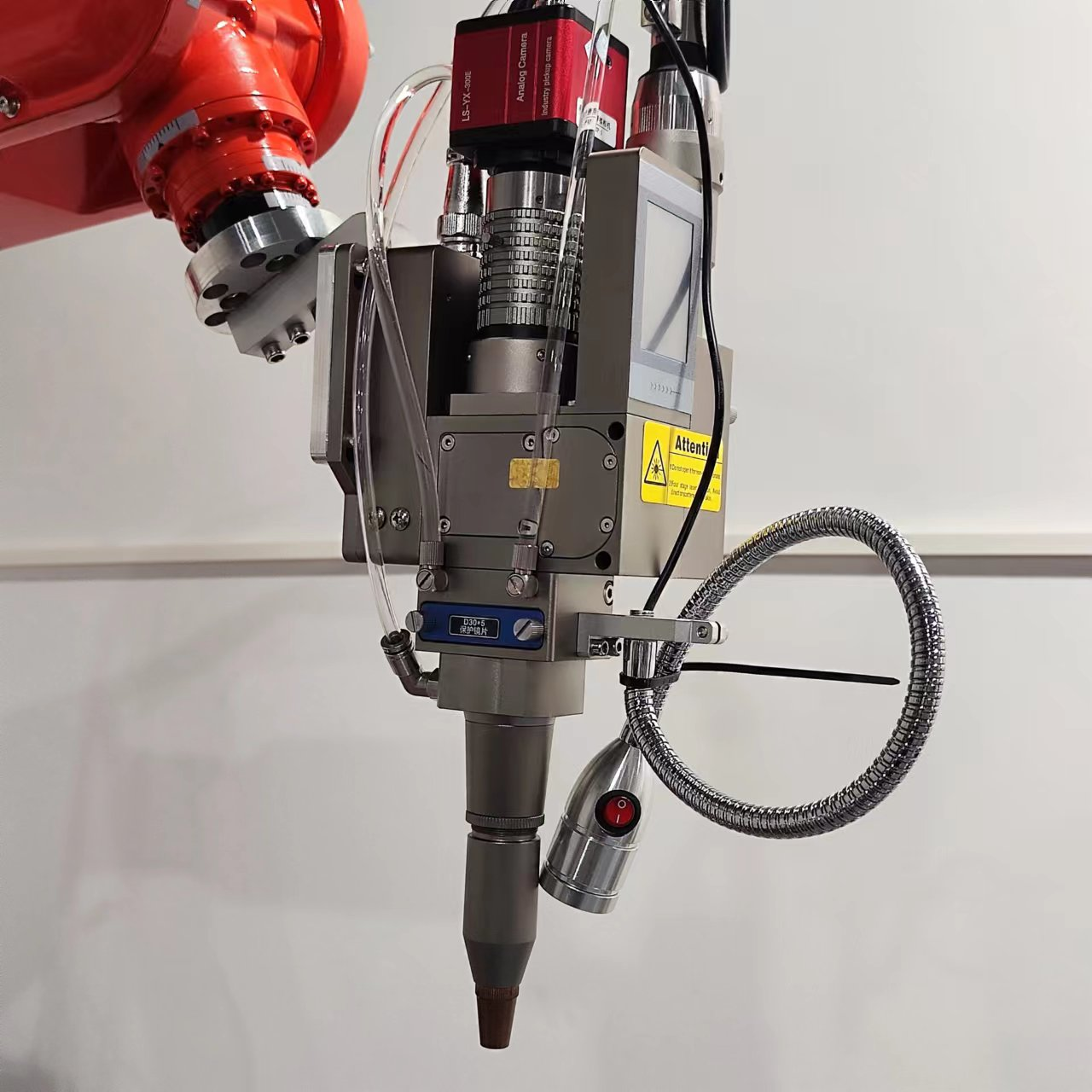

Malunga neMavenLaser

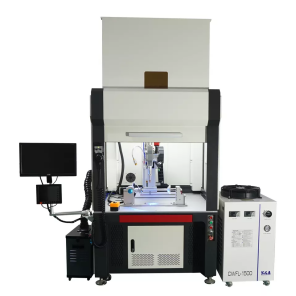

I-Maven Laser yinkokeli yesicelo soshishino lwelaser e-China kunye nomboneleli ogunyazisiweyo wezisombululo zokusetyenzwa kwe-laser yehlabathi. Siyiqonda ngokunzulu indlela yophuhliso loshishino lokuvelisa, sityebisa rhoqo iimveliso zethu kunye nezisombululo, sigxininisa ekuphononongeni ukudityaniswa kwe-automation, ulwazi kunye nobukrelekrele kunye neshishini lemveliso, ukubonelela ngezixhobo zokuwelda i-laser, izixhobo zokuphawula nge-laser, izixhobo zokucoca i-laser kunye negolide ye-laser kunye nobucwebe besilivere. izixhobo zokusika kumashishini ahlukeneyo kubandakanywa uchungechunge lwamandla apheleleyo, kwaye ngokuqhubekayo ukwandisa impembelelo yethu kwintsimi yezixhobo ze-laser.

Ixesha lokuposa: Jan-13-2023