Ngophuhliso oluqhubekayo lwesayensi kunye netekhnoloji kunye nokwandiswa kweenkalo ezahlukeneyo zezicelo,laseriteknoloji processing ngokuthe ngcembe ukungena kuzo zonke iinkalo zobomi kwaye ibe sisixhobo processing ebalulekileyo. Ukusetyenziswa kwelaser,i-kilowatt-level MOPA(I-Master Oscillator Power-Amplifier) iilaser zisetyenziswa ngokubanzi kwiinkalo ezifana nokusetyenzwa kwezinto kunye novavanyo lophando lwezenzululwazi ngenxa yamandla abo aphezulu, ukungena okunamandla, kunye nefuthe eliphantsi lobushushu. Zisisixhobo esibalulekileyo sokunceda amashishini aphucule umgangatho kunye nokwandisa imveliso. Isixhobo esifanelekileyo sokusebenza kakuhle. Kodwa ngokuchanekileyo ngenxa yamandla ayo aphezulu, ukwenzela ukwandisa ukusebenza kakuhle kwe-kilowatt-level MOPA laser, ukukhethwa kwezixhobo kubalulekile. Kuphela ngokukhetha izincedisi ze-laser ezifanelekileyo sinokuqinisekisa ukuba i-laser inokusebenza ngokuzinzileyo nangokufanelekileyo kwaye ihlangabezane ngcono neemfuno ezahlukeneyo zesicelo.

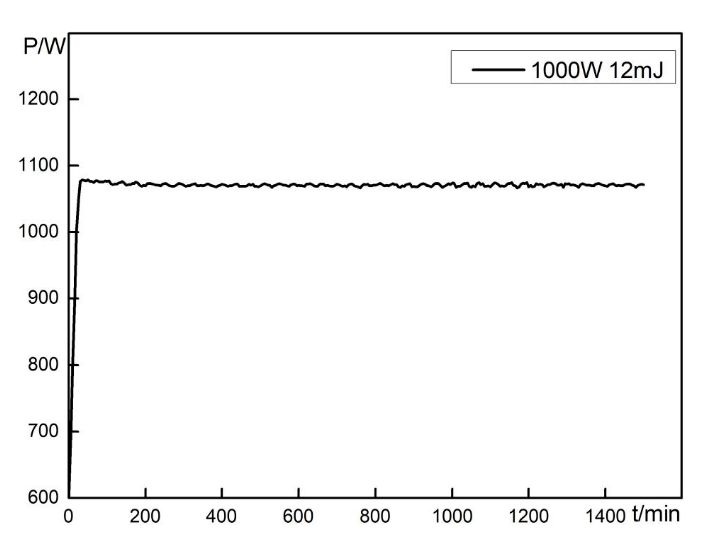

Ukuzinza kwamandla aphezulu

Ukuveliswa kobuninzi be-kilowatt-level MOPA kunye nokusebenza okuphezulu kunye nezibonakaliso zobugcisa

Ukukwazi ukuzinza ngobuninzi-imvelisoi-kilowatt-level yemowudi enye ye-MOPA lasersLuphawu olubalulekileyo lwenkampani yeMOPA laser R&D, imveliso kunye namandla okwenza. I-MAVEN okwangoku ineenguqu ezininzi ze-MOPA ze-fiber laser zokucoca i-laser eziphezulu zamandla ezinokuhlangabezana neemfuno zokulungiswa kwezicelo ezahlukeneyo kwimilinganiselo emininzi.

Ukuguquguquka kwemveliso ye-24h epheleleyo kungaphantsi kwe-<3%

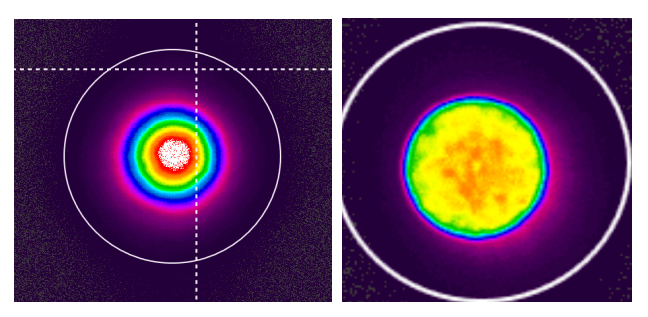

Umgangatho weBeam uyalawuleka

Umqa weGaussian onemowudi enye Iimowudi ezininzi ze-flat-top beam

Itekhnoloji yokudibanisa impompo yokuphela kwempompo, ukuhanjiswa kwenqanaba lamandla esulungekileyo kunye nengqiqweni, inkqubo ekhethekileyo yokudibanisa imveliso, kunye nemowudi eyodwa ephezulu yamandla ecolisiweyo i-isolator enekristale ebalaseleyo yobushushu, ngelixa amandla aphumayo afikelela kwi-1000W, inokuqinisekisa umgangatho obalaseleyo weBeam.

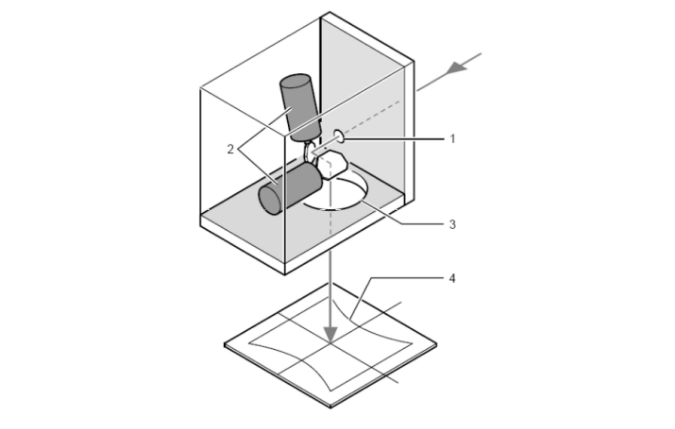

Kwintsimi ye-fiber laser processing, ngokukodwa ukulungiswa kweamandla aphezulu e-MOPA nanosecond pulse fiber laser, ngenxa yamandla aphezulu aphezulu, amandla amakhulu e-pulse kunye ne-frequency ephezulu, ukukhethwa kwezixhobo kubaluleke kakhulu. Izixhobo eziphambili ezichaphazela umphumo wokucubungula we-high-power pulse laser ziquka i-Scanning galvanometer, igxininisa isibuko sentsimi kunye nesibonisi.

Unokukhetha njani igalvanometer yokuskena?

Injongo yetekhnoloji yokuskena i-galvanometer kukugqiba isantya esiphezulu, imisebenzi echanekileyo yokuskena. Kukho izinto ezimbini eziphambili zokumisela. Enye yinkqubo yokulawula enokufikelela kwisantya esiphezulu kunye nokuchaneka okuphezulu, kwaye enye i-galvanometer enesantya sokuphendula ngokukhawuleza. iskena. Ubume be-galvanometer ikakhulu bunamacandelo amathathu: i-reflector, i-motor kunye nekhadi lokuqhuba, phakathi kwayo i-lens ibalulekile ekuzinzeni kokulungiswa.

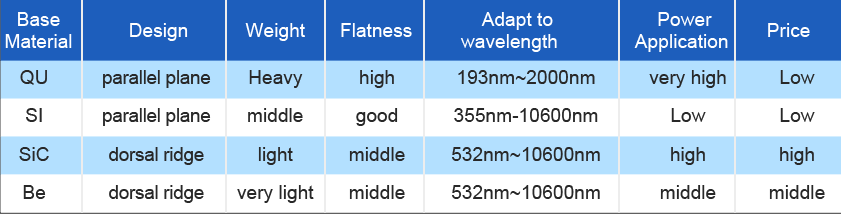

Izinto zelensi yeGalvanometer kunye nezalathi ezichaphazelayo

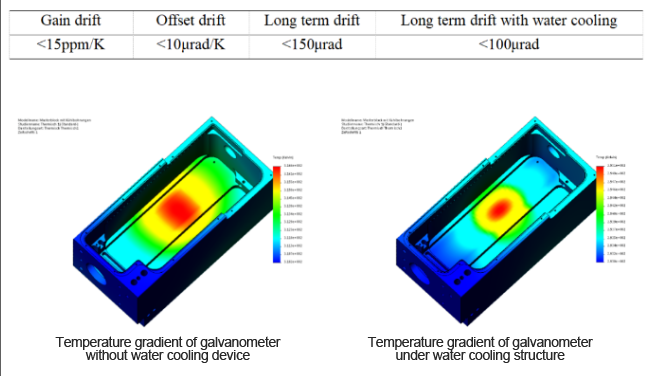

Inkqubo yolawulo lwe-thermal yeukuskena galvanometerikwayinto ebalulekileyo ekuqinisekiseni uzinzo lwexesha elide lokuqhuba. Ukwahluka kobushushu kuya kubangela ukuba i-galvanometer iqhube kwaye inciphise ukuchaneka kokubeka. Amaxabiso aqhelekileyo ngala alandelayo. Ngokusebenzisa ukutshatyalaliswa kobushushu obusebenzayo bokupholisa kwamanzi, ukuzinza kwexesha elide kunokuphuculwa ngama-30%.

Ixabiso eliqhelekileyo lokukhukuliseka kobushushu begalvanometer

Isixhobo sokupholisa amanzi sinokususa ngokufanelekileyo ukushisa kwaye siqinisekise ukusebenza okuzinzile kwexesha elide le-galvanometer. Ezona ndlela zingundoqo zobugcisa kukufumana indawo ephantsi yokupholisa amanzi anesiphithiphithi ngoyilo olulungisiweyo lomjelo wamanzi okupholisa, kunye nokuyila ubume besixhobo sokutshintshiselana kobushushu obusebenzayo bangaphandle.

Kwi-kilowatt-level high-power MOPA pulse laser system, sincoma kakhulu ukusetyenziswa kweelensi zequartz ezikumgangatho ophezulu kunye neenkqubo zegalvanometer ezineenkqubo zokupholisa amanzi.

Indlela yokukhetha i-lens yentsimi yokugxila?

I-lens yentsimi igxininise i-laser beam edibeneyo kwinqanaba, inyusa ukuxinana kwamandla kwi-laser beam, kwaye isebenzisa amandla aphezulu e-laser ukwenza izinto ezahlukeneyo zokulungisa izinto ezifana nokusika, ukumakishwa, i-welding, ukucoca kunye nonyango lwangaphandle.

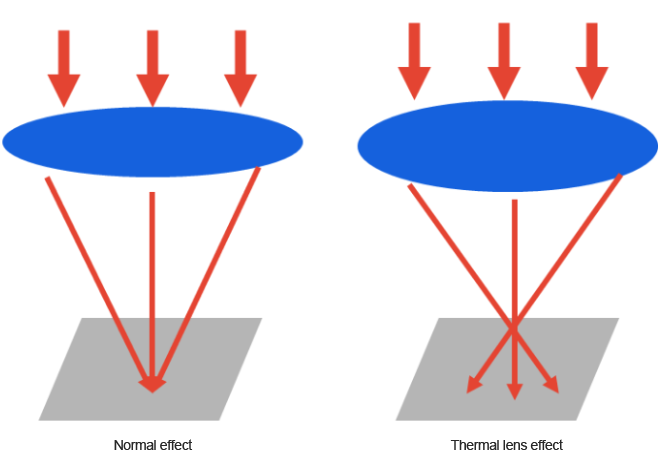

Izinto eziphambili ezichaphazela umgangatho wokucubungula kunye nesiphumo se-lens yentsimi zizinto eziphathekayo zensimu kunye nokuphakama kwe-adapter ring. Izinto eziphambili zelensi yentsimi yiglasi kunye ne-quartz. Umahluko phakathi kwezi zibini zilele kwi-lens ye-thermal effect kumandla aphezulu. Emva kokuba i-lens yentsimi egxininisekile ihlanjululwa ngokuqhubekayo yi-laser beam ixesha elide, iya kuvelisa i-thermal deformation ngenxa yokunyuka kweqondo lokushisa, eliya kubangela ukuhanjiswa kwe-optics. Isalathiso se-refractive se-element kunye nesalathiso sokubonakaliswa kwenguqu ye-reflection optical element, kunye ne-thermal lens effect iya kuchaphazela imo ye-laser kunye nesikhundla sokugxila emva kokugxila, okuya kuchaphazela kakhulu umphumo wokucubungula. I-Quartz ine-coefficient yokwandisa i-thermal ephantsi kunye nokuhanjiswa okuphezulu, okwenza kube yinto engcono yokuzikhethela iilensi zentsimi zamandla aphezulu. Ukuba kuyimfuneko, imodyuli yokupholisa amanzi kufuneka yongezwe.

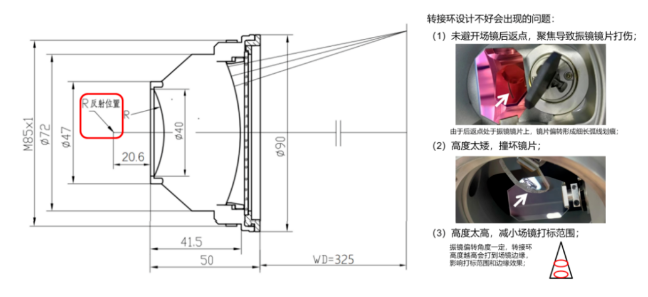

I-adapter ring yokufanisa i-lens yentsimi kwi-galvanometer nayo yinto ebalulekileyo echaphazela izixhobo kunye nokusebenza. Ukuphakama okufanelekileyo kwendandatho ye-adapter kunokuphepha indawo yokubuyela kwi-lens yentsimi kunye nokuqinisekisa ifomathi yokucubungula. Ukuba iphezulu kakhulu okanye iphantsi kakhulu, iya kubangela iingxaki ezihambelanayo.

Kwiinkqubo ze-kilowatt-level high-power MOPA pulse laser, sincoma kakhulu ukusetyenziswa kwezibuko zentsimi ze-quartz eziphezulu kunye neemodyuli zokupholisa amanzi kunye nendandatho ye-adapter yesibuko esizinikezeleyo yobude obufanelekileyo.

Indlela yokudibanisa iilensi ezikhanyayo?

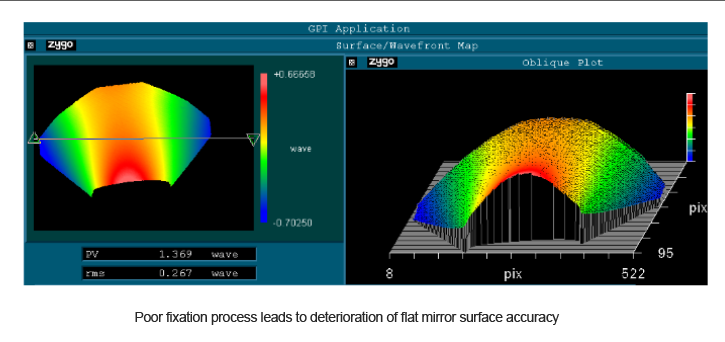

Umsebenzi oyintloko weelensi ezikhanyayo kwisakhiwo sendlela ye-optical kukutshintsha ulwalathiso lwendlela ye-optical path. Ukukhetha iilensi ezibonisa umgangatho olungileyo kunye neendlela zofakelo olusemgangathweni kunokudlala indima enkulu kwezinye izicelo ezikhethekileyo, kodwa iilensi ezikumgangatho ophantsi kunye neendlela zofakelo olungekho ngqiqweni nazo ziya kubangela umbuzo omtsha. Iimpawu eziphathekayo zelensi zichongwa yi-wavelength kunye namandla e-laser. I-substrate ngokubanzi yenziwe nge-quartz edibeneyo okanye i-crystalline silicon. Ifilimu ebonisa i-laser yenziwa ngokubanzi ngefilimu yesilivere okanye ifilimu ye-dielectric ecacileyo, enokubonakala okuphezulu, izinga lokufunxa eliphantsi kunye nokumelana ne-laser. Iimpawu zomda womonakalo ophezulu.

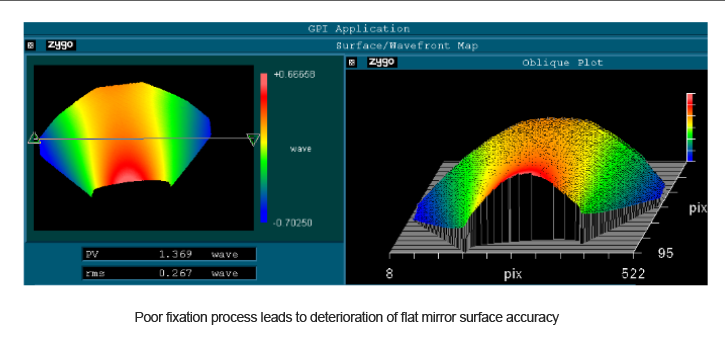

Isibonisi senqwelo-moya esifanelekileyo asiyi kuchaphazela umgangatho wogxininiso, kodwa ekusetyenzisweni okwenyani, inqwelomoya ebonakalisayo inokonakala ngenxa yezinto ezixineneyo ezifana ne-screw fixation, efana nesibuko esiyicylindrical. Ukugqwethwa kuchaphazela ubukhulu becala ubulunga bendawo ekugxilwe kuyo, kubangele i-astigmatism ephantsi kunye ne-astigmatism ekumgangatho ophantsi. Ukuchithwa kuthintela indawo ekugxilwe kuyo ekufikeleleni kumda we-diffraction, echaphazela umgangatho wokucubungula kunye nesiphumo.

Kwiinkqubo ze-kilowatt-level high-power MOPA pulse laser, sincoma kakhulu ukusetyenziswa komgangatho ophezulu we-quartz reflectors kunye neendlela ezifanelekileyo zokufakela ukuqinisekisa ukuba iilensi zithwala amandla ngaphandle kokuguqulwa.

Ixesha lokuposa: Sep-13-2023