Undoqo wokucocwa kwelaser kukuxinaniswa kwamandla okuphezulu kwe-laser beam irradiation kumphezulu we-workpiece, ukungcola, i-oxidation, i-plating okanye i-coating, njl. okanye ukuhlutha, ukwenzela ukuba ufezekise indawo ecocekileyo ye-workpiece ngaphandle kokulimaza inkqubo ye-substrate, lukhetho olufanelekileyo kwisizukulwana esitsha sokucoca iteknoloji yokucoca.

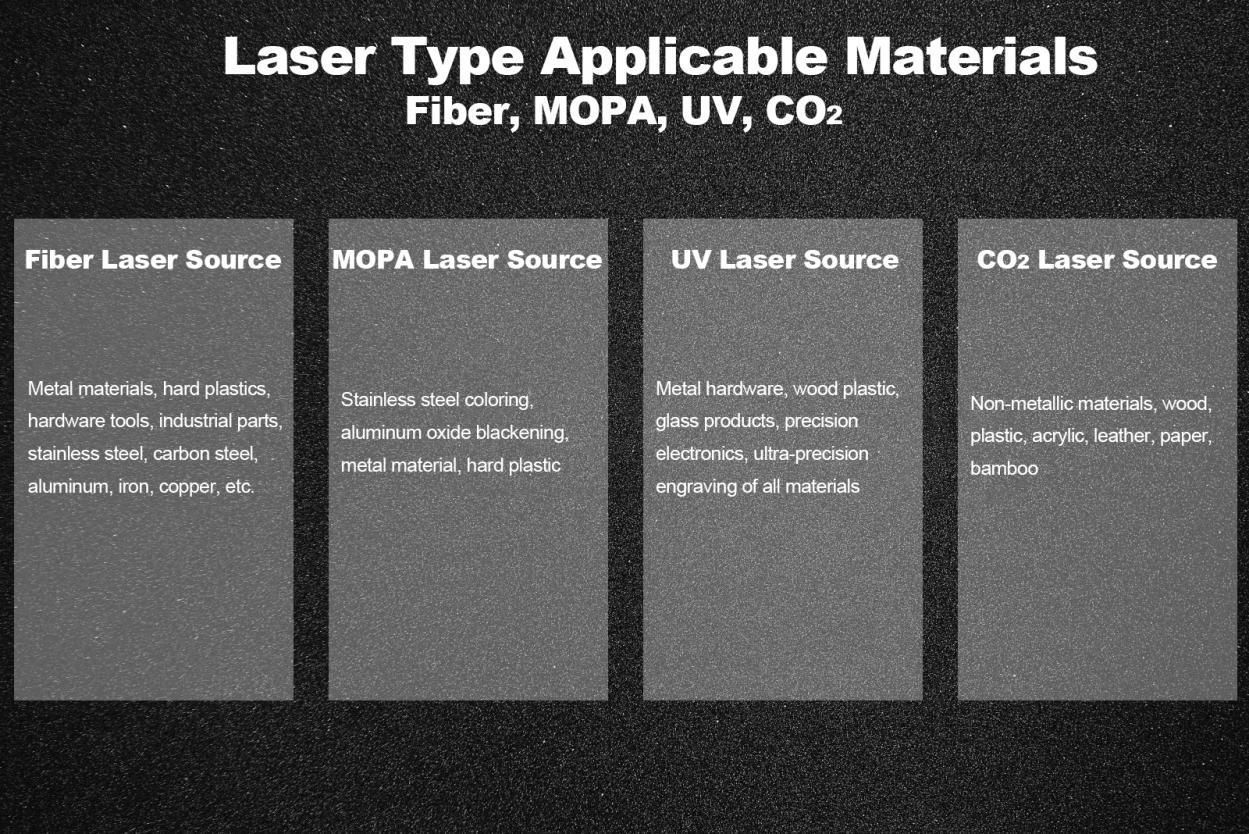

Uhlobo lweLaser Izinto eziSebenzayo

Uphuhliso lweLaser ngaxeshanye lukhuthaza uphuhliso olukhawulezayo lwetekhnoloji yokucoca i-laser yaseTshayina, itekhnoloji yokucoca i-laser iye yaba bubuchwephesha bokucoca obuyimfuneko kwimizi-mveliso, elwandle, kwi-aerospace kunye namanye amasimi okuvelisa akumgangatho ophezulu, kubandakanya nokususwa kokungcola kwerabha umphezulu wokubumba kwamatayara, ukususwa kwezingcolisi zeoli ye-silicone kumphezulu wefilimu yegolide kunye nokucocwa okuphezulu kokucocwa kweshishini le-microelectronics.

Ukususwa kwe-Metal surface rust, ukususwa kwepeyinti, ukususwa kweoli kunye nokususwa kwe-oxide layer yeyona nto isetyenziswayo ngoku kwintsimi yokucoca i-laser. Phakathi kwee-laser ezahlukeneyo kwi-wavelength, amandla kunye nezinye iiparitha ezibalulekileyo zomahluko, izixhobo ezahlukeneyo, amabala kwi-laser wavelength, amandla kunye nezinye iimfuno zahlukile, kumsebenzi wokucoca wokwenyani kufuneka ukhethe iindlela ezahlukeneyo zokucoca i-laser ngokwemeko yokwenyani.

Emva kwenani elikhulu lokuqinisekiswa kovavanyo lwenkqubo yeMavenLaser yophando kunye neqela lophuhliso, i-MOPA laser, i-laser edibeneyo yeyona ndawo isetyenziswa kakhulu kwimarike yokucoca i-laser, ilandelwa linani elincinci lezicelo ze-carbon dioxide lasers, i-ultraviolet lasers, i-laser eqhubekayo.

1.MOPA ipulsed laser yokucoca izinto ezahlukeneyo zokucoca umphezulu

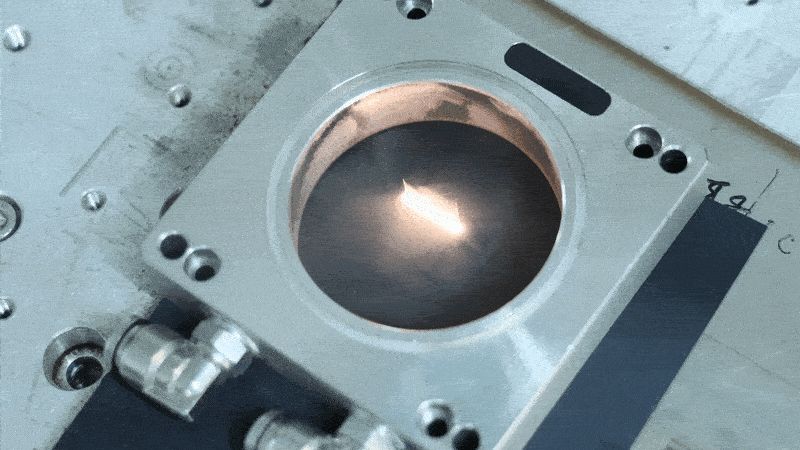

I-cavity ye-resonant ye-MOPA i-fiber laser system ngokwayo i-fiber optical, kunye ne-MO (i-Master Oscillator) yi-laser yamandla aphantsi, ekhethwa ngokubanzi ngenxa yobude bayo obufanelekileyo. I-laser LD yamandla aphantsi (i-laser Diode) inokumodareyitha iiparamitha zemveliso ngokuthe ngqo kwi-drive yangoku, kwaye emva koko ukukhanya komqondiso oveliswa yi-LD kudityaniswa kwi-PA (Amandla Amplifier) inkqubo yokukhulisa amandla nge-pigtail yokwandisa ukukhanya komqondiso.

I-laser ye-MOPA yeyona nto isetyenziswa kakhulu ukucocwa kwe-laser, kuba inkqubo ye-laser ye-MOPA ifayibha inokudityaniswa ngokungqongqo kwinkqubo yomthombo wesiginali yembewu yokukhulisa, ayizukutshintsha iimpawu ze-laser ezifana nobude obuphakathi, i-pulse waveform kunye nobubanzi be-pulse. Ke ngoko, umlinganiselo wohlengahlengiso lweparamitha uphezulu kwaye ubanzi, kwiimeko ezahlukeneyo zokusetyenziswa kwezixhobo ezahlukeneyo, ukulungelelaniswa ngakumbi kunye nekhefu lefestile lenkqubo likhulu, ukuhlangabezana nokucocwa komphezulu kwezinto ezahlukeneyo.

Ukongeza, i-laser ye-MOPA inomda ophezulu we-laser wamandla, inokuphuculwa ngokuphucula isixhobo sokucoca i-laser, njengokunyusa indawo yokucoca i-laser, kunye neenkqubo ezikrelekrele, njl., ukufezekisa ukuphuculwa kwezixhobo zokucoca i-laser. Kufanelekile ukukhankanya ukuba ngenxa yokusebenza okugqwesileyo kunye nokusebenziseka kwemeko eguquguqukayo yelaser ye-MOPA, isetyenziswa kakhulu ngakumbi kwiibhetri zamandla amatsha nakwamanye amashishini asakhasayo.

| Ibhetri yaMandla amaNtsha | Ukucocwa kwepali yebhetri ye-lithium, ukucocwa kweentsika zepali, ukucocwa kwesitofu se-liquid port, ukucocwa kwekhava, ukucocwa kwefilimu eluhlaza okwesibhakabhaka, njl. |

|

I-Aerospace | Ukucocwa kweendawo ze-injini ngaphambi nasemva kwe-welding, ukucocwa kwetanki yokugcina isithuthi phambi nasemva kwe-welding, ukususwa kwepeyinti kwizinto ezidibeneyo, ukukhutshwa kwe-arhente yokukhulula, ukususwa kwesikhumba senqwelomoya, ukususwa kwesitywina, ukucocwa |

| Iimveliso zokungunda | Imibumbo yeTire, i-encapsulation molds, i-injection molds, i-ring molds yokutywina, i-molds yokutya, njl njl. |

| Ishishini le-3C | Ukukhetha ibhodi yesekethe kunye nokususwa kwepeyinti, ukucocwa kwewafer, ukususwa kwepeyinti yeselfowuni, ukucoca i-PVD yokucoca ijig |

| UkuVeliswa kweeMoto | Ukucoca umzimba kwangaphambili, ukucocwa kwevili, ukususwa kwepeyinti kwiindawo ezikhethiweyo zomzimba, amathayi athule |

| Iinqanawa zaseLwandle | Ukucoca kwangaphambili kunye ne-post-weld, iinxalenye zokususwa kwepeyinti, ukucocwa kokususwa kweoli |

| Ibhulorho, ukulungiswa kohola wendlela | Iindawo zesakhiwo sebhulorho ukususwa kwepeyinti, ukususwa komhlwa, ukususwa kwepeyinti yonogada behola wendlela |

| Uthutho lukaloliwe | Ukucoca umzimba we-Aluminiyam ngaphambi nangemva kwe-welding, i-wheel pair yokucoca ngokuzenzekelayo, ukucoca i-bogie, ukucocwa kwemoto, njl. |

| Petrochemicals | Ukususwa kweqonga le-oyile ngaphandle konxweme, ukususwa kwepeyinti yombhobho, ukususwa komhlwa, njl. |

| Ishishini lokutya | Iipani zokubhaka isinyithi, iimbumba, njl. |

| Vacuum indebe | Ukususwa kwepeyinti engezantsi kunye nodonga lweekomityi ezigqunyiweyo |

| Amanye amashishini | Isihluzo se-oyile yesinyithi, ukucocwa kwetyhubhu yokucoca, ukupolisha kwentsimbi, ukususwa komhlwa kwelaser, ukususwa kweoxide |

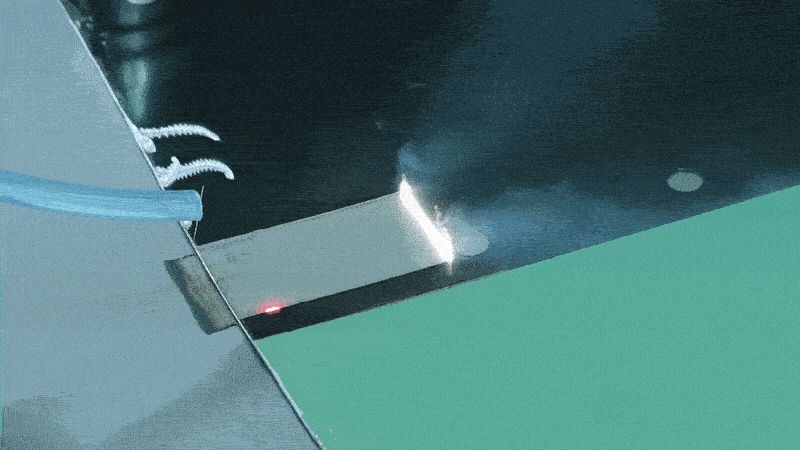

I-2.I-laser composite yokucoca, ukhetho olungcono kakhulu lokususwa kwepeyinti

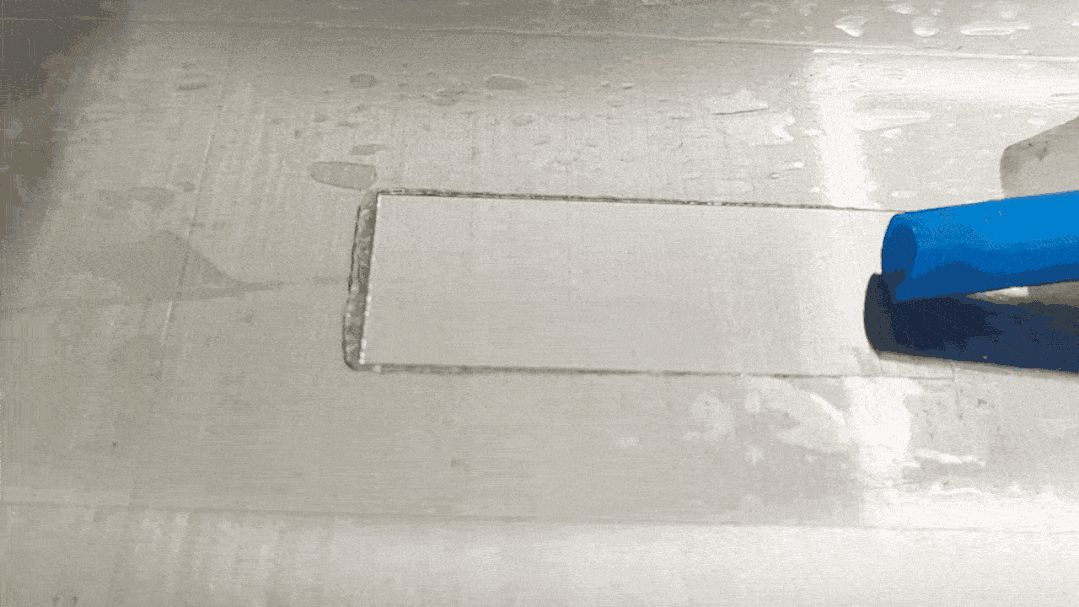

Ukucocwa kwe-laser composite ngokusebenzisa i-semiconductor eqhubekayo ye-laser njengemveliso yokudlulisa ubushushu, ukuze i-adhesives icocwe ifunxa amandla ukuvelisa umphunga, amafu e-plasma, kunye nokwakhiwa koxinzelelo lokwandisa ukushisa phakathi kwezinto zetsimbi kunye ne-adhesives, ukunciphisa amandla okudibanisa phakathi Imigangatho emibini. Xa i-laser imveliso ye-laser ye-high-energy pulse beam, i-wave ye-vibration ebangelwa yi-vibration ukuze ibhondi ingabi zincamathelisi eziqinileyo ngokuthe ngqo kumphezulu wesinyithi, ngaloo ndlela kufezekiswa ukucocwa kwe-laser ngokukhawuleza.

Ukususwa kwepeyinti yepeyinti yeseli yamandla

Ukucoca i-Laser composite ngelixa i-laser eqhubekayo kunye ne-pulse laser esebenzayo edibeneyo, eyenza i-1 + 1> iimpawu ze-2 zokucwangcisa. Isantya esikhawulezayo, ukusebenza kakuhle okuphezulu, umgangatho wokucoca okufanayo ngakumbi, kwizinto ezahlukeneyo, ungasebenzisa amaza ahlukeneyo okucoca ngelaser ngaxeshanye ukufezekisa injongo yokususwa kwamabala.

Ukususwa kwepeyinti yeenjini zeenwele

Okwangoku, ukucocwa kwe-laser composite kusetyenziswa kakhulu kwiinqanawa, ukulungiswa kwe-auto, ukubunjwa kwerabha, izixhobo zoomatshini bokugqibela, uloliwe kunye nokukhuselwa kwendalo kunye nezinye iindawo, ukususa ngokufanelekileyo i-resin surface, ipeyinti, ioli, amabala, ukungcola, i-rust, i-coating. , iplating kunye ne-oxide layer.

Umzekelo, kucociso lwe-laser etyebileyo yokucoca, i-laser enye yokukhupha amandla amaninzi, ixabiso eliphezulu, ukusetyenziswa kwe-laser ye-pulsed laser - semiconductor laser composite yokucoca, inokuphucula ngokukhawuleza nangempumelelo umgangatho wokucoca, kwaye ayibangeli monakalo isubstrate; kwi-alloy ye-aluminium kunye nezinye izinto ezibonisa kakhulu ukucocwa kwe-laser, i-laser reflectivity eyodwa kunye nezinye iingxaki. Ukusetyenziswa kwe-laser ye-pulsed laser - semiconductor laser compound yokucoca, kwindima ye-semiconductor laser thermal conductivity transfer, ukwandisa izinga lokufunxa amandla omgangatho we-oxide wesinyithi, ukwenzela ukuba i-pulse laser beam inokukhawuleza ukuhluba umaleko we-oxide, ukuze ukuphucula ngokufanelekileyo ukusebenza kakuhle kokususa, ngakumbi ukongeza ekusebenzeni kwepeyinti kwandiswe ngamaxesha angaphezu kwama-2.

3.I-Carbon dioxide laser yokucoca, ukhetho olungcono kakhulu lokususa izinto ezingezizo zetsimbi

I-CO2 lasers ziigesi ze-laser ezinegesi ye-CO2 njengento esebenzayo, ezaliswe yigesi ye-CO2 kunye nezinye iigesi ezincedisayo (i-helium kunye ne-nitrogen kunye nenani elincinci le-hydrogen okanye i-xenon), enolwalathiso olungcono, i-monochromaticity kunye nokuzinza rhoqo. Ekubeni ityhubhu yokukhupha iqhele ukwenziwa ngeglasi okanye imathiriyeli yequartz, iintlobo ezimbini eziqhelekileyo ze-CO2 lasers yithubhu yeglasi CO2 lasers kunye ne-metal RF tube CO2 lasers.

Ukususwa kweentsini

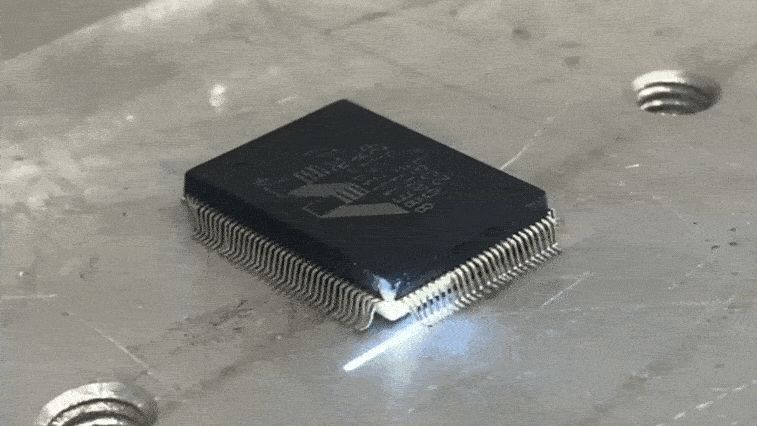

I-4.UV yokucoca i-laser yezixhobo ezichanekileyo

Iilaser eziphambili ze-UV ezisetyenziselwa i-laser microfabrication zi-laser ze-excimer kunye ne-laser-solid-state lasers. I-laser ye-UV enobude obufutshane obufutshane kunye namandla aphezulu e-photon enye inokwaphula ngokuthe ngqo imibhobho yekhemikhali eqhagamshelwe phakathi kwezixhobo, kwaye izixhobo zihluthwe kumphezulu ngendlela yerhasi okanye amasuntswana, kwaye indawo echaphazeleke bubushushu eveliswayo ngexesha lokusetyenzwa incinci. iingenelo ezizodwa kwi-microfabrication, ezifana Si, GaN kunye nezinye izixhobo semiconductor, quartz, isafire kunye nezinye iikristale optical, kunye polyimide (PI), polycarbonate (PC) kunye nezinye izinto polymer, kwaye inokuphucula ngempumelelo umgangatho wokuvelisa.

Ukucoca iphini yetshiphu

I-laser ye-UV ithathwa njengesona sisombululo silungileyo sokucoca i-laser kwintsimi ye-elektroniki echanekileyo, eyona nto ibonakalisa i-teknoloji "ebandayo" yokucoca iteknoloji ayitshintshi iipropati ezibonakalayo zento ngaxeshanye, i-micro-processing and processing, ingaba zisetyenziswe ngokubanzi kumashishini ahlukeneyo kunye neenkalo ezifana nonxibelelwano, optics, umkhosi, uphando lolwaphulo-mthetho, unyango. Umzekelo, ixesha le-5G lenze imfuno yemarike yokulungiswa kwe-FPC. Ukusetyenziswa komatshini we-laser we-UV kwenza kube lula ukucwangciswa okuchanekileyo okubandayo kwe-FPC kunye nezinye izinto.

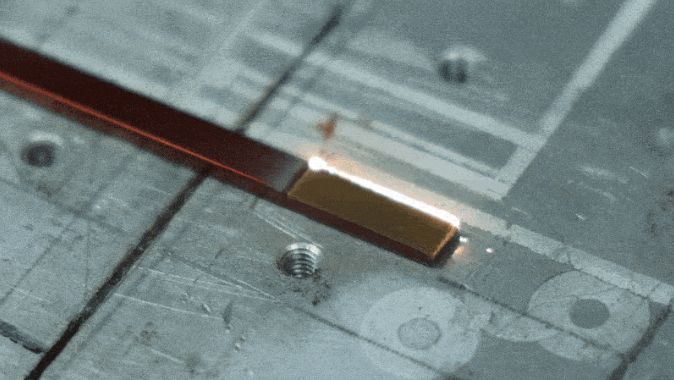

I-5.I-fiber eqhubekayo yokucoca i-laser ukususa i-rust edadayo kwiindawo zentsimbi

I-fiber ye-laser eqhubekayo isebenza ngokumpompa ukukhanya ukusuka kumthombo wempompo ngesibonisi esidityaniswe kwindawo yokufumana, kuba indawo yokuzuza yinto enqabileyo yomhlaba ifayibha ene-doped, ngoko ke ukukhanya kwempompo kuyafunxwa, amandla e-photon anqabileyo anqabileyo emhlabeni. kwaye ufezekise ukuguqulwa kwenombolo ye-particle, emva kokuguqulwa kwe-particle ngokusebenzisa i-cavity resonant, ukusuka kwi-excited state jump back to the ground state, ukukhulula amandla, kunye nokwenza i-laser output ezinzile, inzuzo enkulu kukuba ukukhanya kunokuqhubeka.

Ukucoca emva kwe-weldingC

Ezona zicelo zokucoca ngelaser, usetyenziso oluqhubekayo lwefiber laser luncinci, kodwa kukho inani elincinci lezicelo, ezinje ngezakhiwo ezinkulu zentsimbi, imibhobho, njl.njl., ngenxa yomthamo omkhulu wokutshatyalaliswa kobushushu ngokukhawuleza, iimfuno zomonakalo we-substrate azikho. phezulu, ngoko ungakhetha i-laser eqhubekayo.

Ukususwa komhlwa

Kufanelekile ukukhankanya ukuba ngokuphumelela kunye nokuzinza kobuchwepheshe bendawo ye-ring, i-laser ye-fiber ye-fiber eneenzuzo zohlengahlengiso olulula lwenkqubo kunye nokusebenza okulula kuye kwaziwa ngokubanzi kwintsimi ye-welding kunye nokucoca, kwaye emva kwenani elikhulu leemvavanyo yi-. Iinjineli zeZiko leNkqubo yeMavenLaser, itekhnoloji isetyenziselwa ukususa umhlwa odadayo, obunokuphucula kakhulu ukusebenza kakuhle kokucoca.

Ngenkqubela phambili yenzululwazi kunye nobuchwepheshe kunye nokuphuculwa kweemfuno zokukhuselwa kwendalo, ukucocwa kwe-laser kuya kuthatha inxaxheba ngokunzulu nangokubanzi kwinkqubo yokuphindaphinda imveliso yokuvelisa yaseTshayina, kwaye ibe yindlela yokucoca imveliso ecocekileyo yoshishino.

I-Shenzhen Maven Laser Automation Co., Ltd., enekomkhulu e-Shenzhen, inesityalo sayo sokuvelisa. Ugxininiso kwintsimi yezicelo ze-laser high-tech, kunye nokusukela imveliso njengeyona njongo iphambili, ukubonelela abathengi nge-laser cutting, i-laser welding, i-laser yokumakishwa, ukucocwa kwe-laser, ukunikezelwa kwamandla e-laser iseti epheleleyo yeenkonzo ezisekelwe kwisisombululo se-laser, ngokutsho. kwimfuno yabathengi, uphuhliso lwenkqubo yokucoca ngokuzenzekelayo ukufezekisa iinjongo zokucoca ezikrelekrele. Kwintsimi yomatshini wokucoca i-laser yindawo ehamba phambili, iimveliso zayo ziquka umatshini wokucoca umatshini wekhabhinethi we-laser, ukutsala intonga yokucoca umatshini wokucoca i-laser, umva wegxalaba umatshini wokucoca i-laser iindidi ezahlukeneyo zokusetyenziswa komatshini wokucoca i-laser. Inkqubo yentengiso yemveliso egqibeleleyo kunye nenkqubo yenkonzo yasemva kokuthengisa ukwenza iimveliso zikhuphisane ngakumbi, iiyure ezingama-24 nangaliphi na ixesha ukuphendula ukubonelela ngekhonkco lemveliso emva kokuthengisa iinkonzo zokugcina . Itekhnoloji yeMavenLaser iya kukuchukumisa ngomgangatho ozinzile wetekhnoloji, ixabiso elifanelekileyo lenkonzo, kwaye ube liqabane lakho elithembekileyo!

Ixesha lokuposa: Jan-16-2023