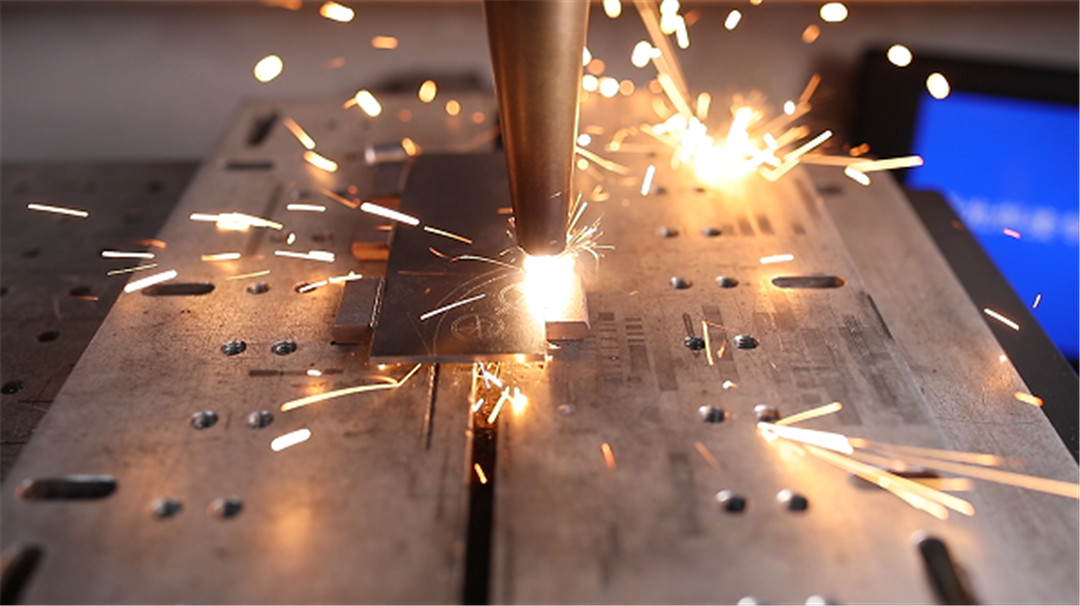

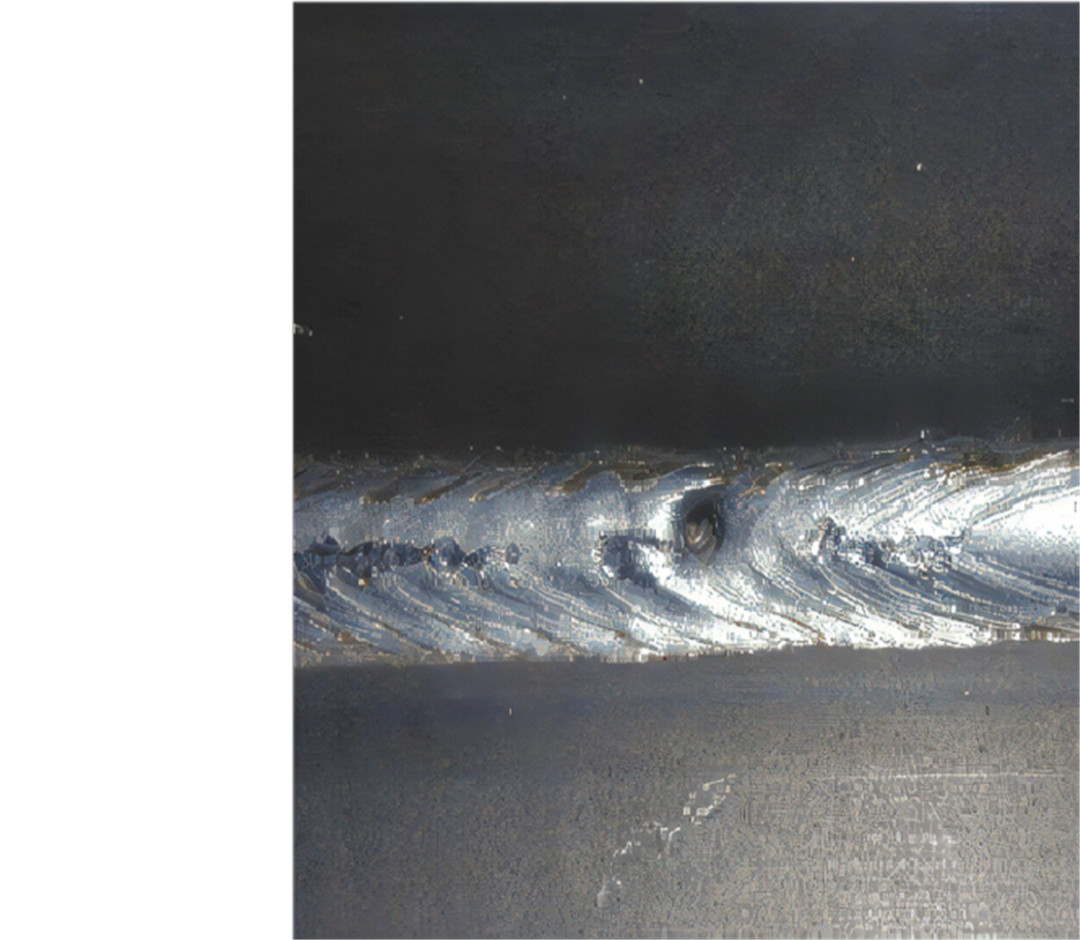

1. Ingxaki: I-slag splash

Kwinkqubo ye-laser welding, izinto ezincibilikisiweyo zitshiza yonke indawo kwaye zibambelela kumphezulu wezinto eziphathekayo, okwenza iinqununu zetsimbi zivele phezulu kwaye zichaphazela ubuhle bemveliso.

Isizathu sengxaki: i-spatter inokuba ngenxa yamandla amaninzi okubangela ukunyibilika ngokukhawuleza, kodwa nangenxa yokuba umphezulu wezinto eziphathekayo awucocekanga, okanye igesi yomelele kakhulu.

Isisombululo: 1, ukulungiswa kwamandla okufanelekileyo; 2, nikela ingqalelo kwizinto zokucoca umphezulu; 3, ukunciphisa uxinzelelo lwegesi.

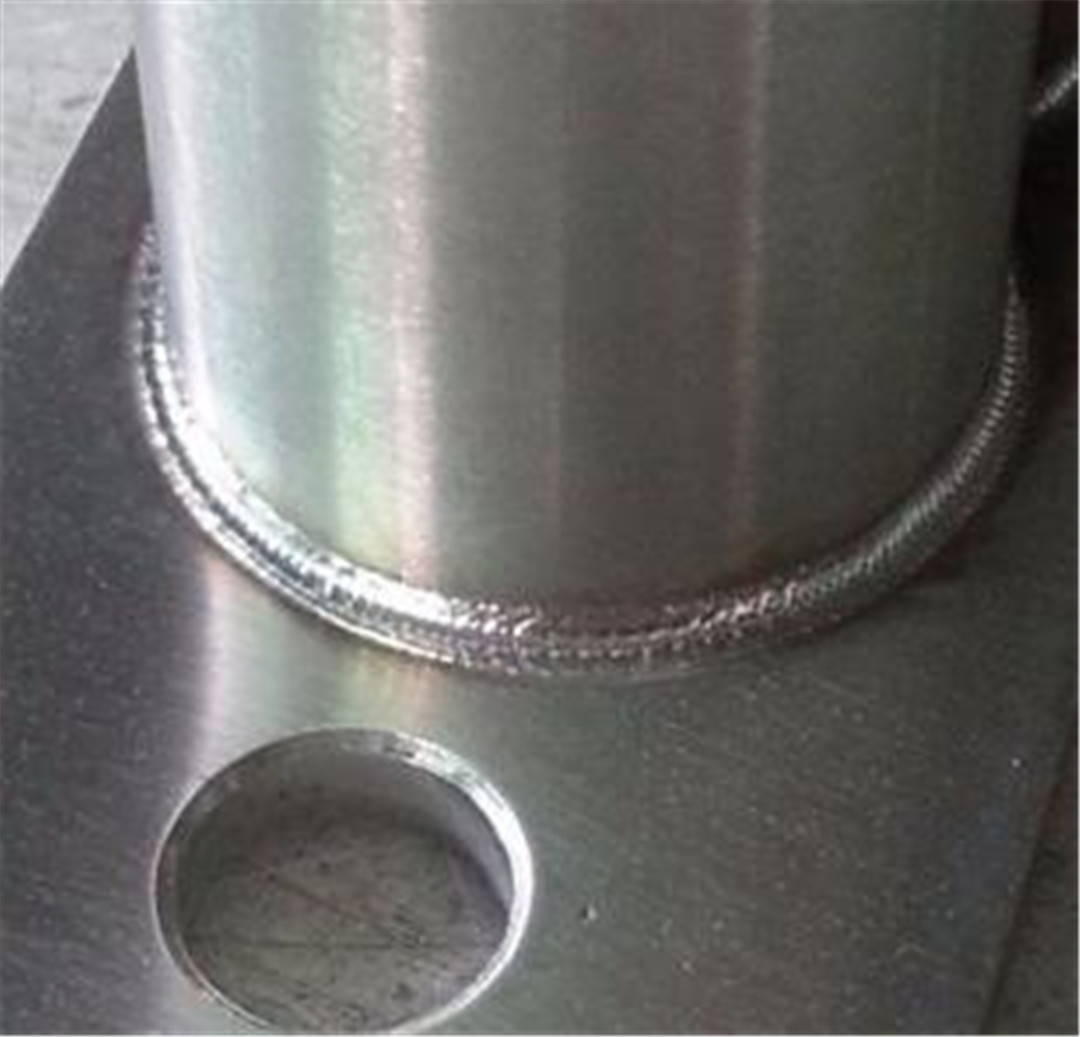

2. Ingxaki: I-weld seam iphezulu kakhulu

I-Welding iya kufumanisa ukuba i-weld seam iphezulu kakhulu kunomgangatho oqhelekileyo, okukhokelela kwi-fat weld seam, ebonakala ingathandeki kakhulu.

Isizathu sengxaki: isantya sokutya kweengcingo sikhawuleza kakhulu, okanye isantya se-welding sicotha kakhulu.

Isisombululo: 1. Nciphisa isantya sokutya kocingo kwinkqubo yolawulo; 2. Yandisa isantya welding.

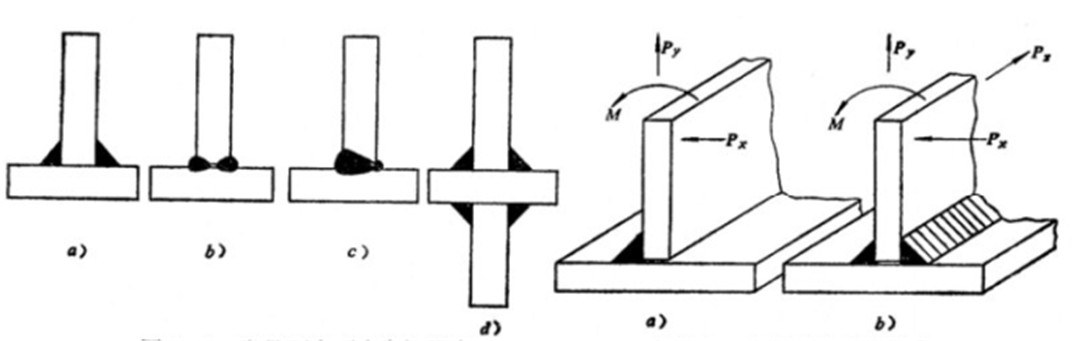

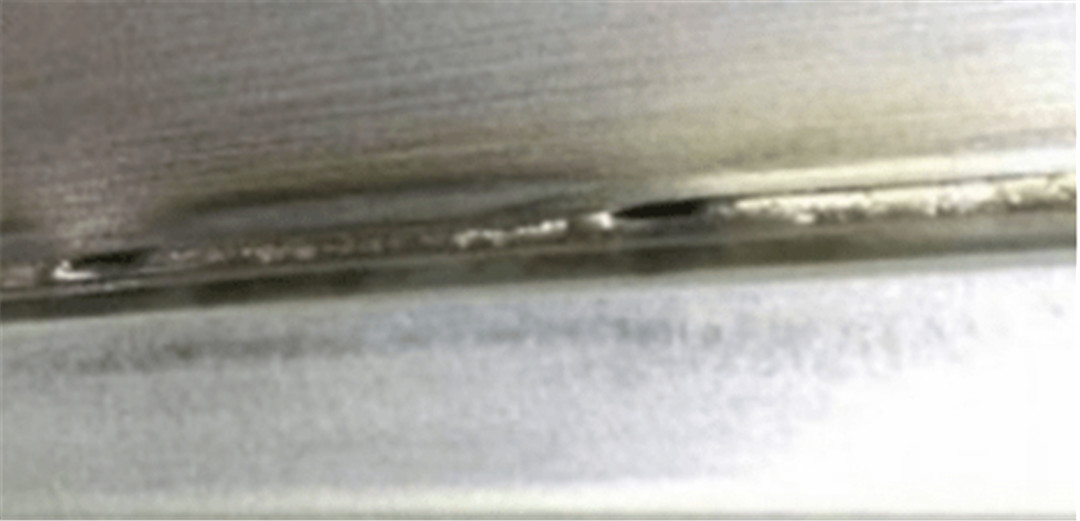

3. Ingxaki: Welding offset

I-Welding ngaphandle kokuqiniswa kumalungu esakhiwo kunye nokumiswa okungachanekanga kunokukhokelela ekungaphumeleli ngokupheleleyo kwe-welding.

Isizathu sengxaki: ukubeka ngendlela engafanelekanga ngexesha le-welding; indawo engahambelaniyo yokutya kocingo kunye ne-laser irradiation.

Isisombululo: 1. Lungisa i-laser offset kunye ne-angle ye-swing ebhodini; 2. Jonga unxibelelwano phakathi kwe-wire feeder kunye nentloko yelaser ukutenxa.

4. Ingxaki: Umbala we-weld umnyama kakhulu

Xa welding steel stainless, aluminiyam ialloy kunye nezinye izinto, umbala weld mnyama kakhulu uya kwenza weld kunye nomphezulu eziphathekayo ukuvelisa umahluko olomeleleyo, kakhulu kuchaphazela ubuhle.

Isizathu sengxaki: amandla e-laser mancinci kakhulu abangela ukutsha okunganeleyo, okanye isantya se-welding sikhawuleza kakhulu.

Isisombululo: 1. lungisa amandla e-laser; 2. lungisa isantya se-welding.

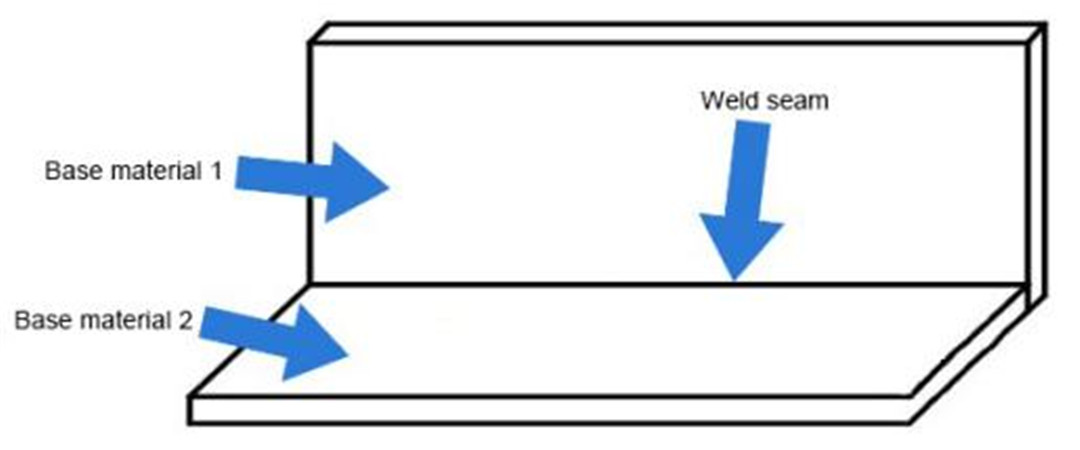

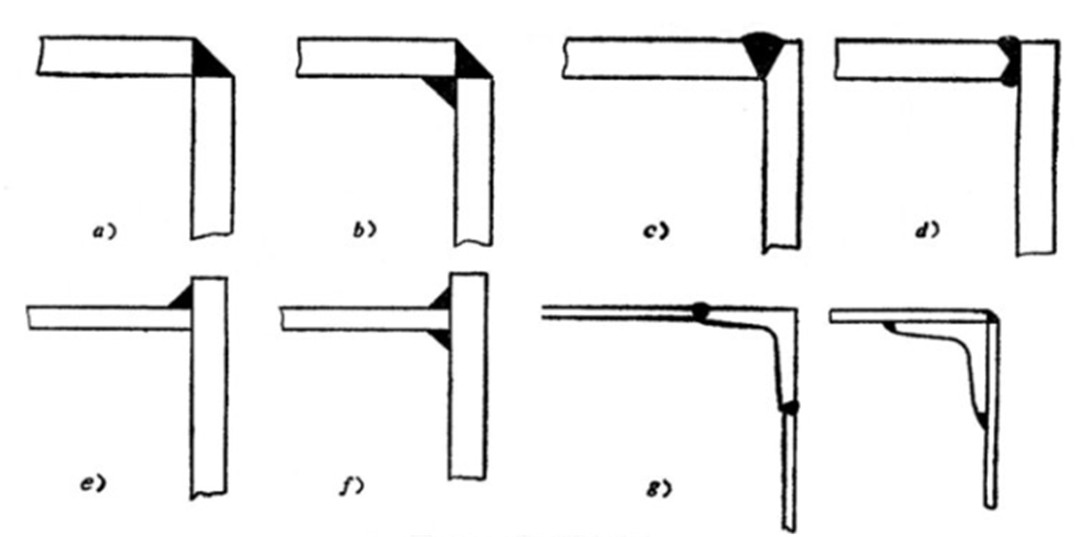

5. Ingxaki: Ukulinganisa i-welding yekona yekona

Xa udibanisa iikona zangaphakathi nangaphandle, iikona azilungiswanga kwisantya okanye kwisigxina, ezinokukhokelela ngokulula kwi-welding engalinganiyo kwiikona, ezichaphazela zombini amandla e-weld kunye nobuhle be-weld.

Unobangela wengxaki: i-welding posture engafanelekanga.

Isisombululo: Lungisa i-offset ekugxilwe kuyo kwinkqubo yokulawula i-laser ukuze intloko ye-laser ephathwayo ikwazi ukwenza imisebenzi ye-welding emacaleni.

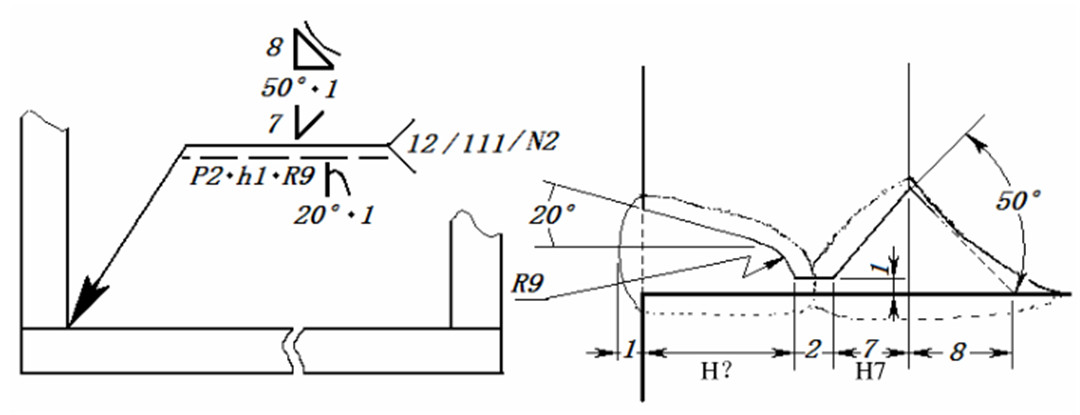

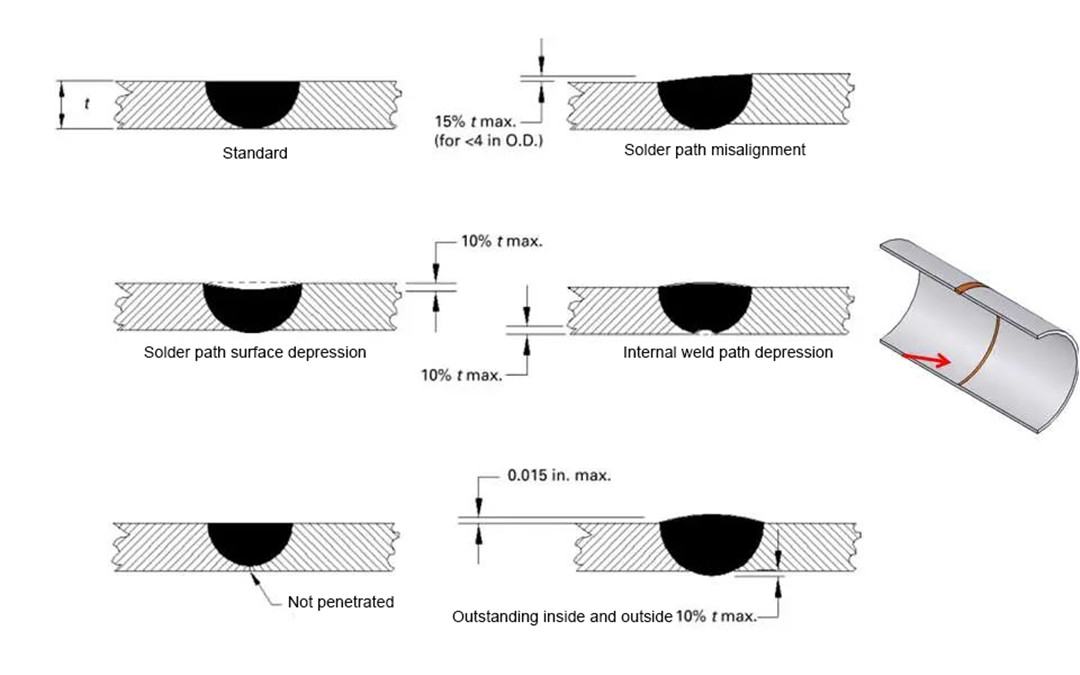

6. Ingxaki: i-welding seam depression

I-Dents kwi-welded joint iya kukhokelela kumandla anganeleyo e-welding kunye neemveliso ezingafanelekanga.

Isizathu sengxaki: Amandla e-laser makhulu kakhulu, okanye ugxininiso lwelaser lubekwe ngokungalunganga, lubangela ukuba i-melt pool ibe nzulu kakhulu kwaye izinto eziphathekayo zincibilike kakhulu, ezikhokelela ekudakaleni kwe-weld seam.

Isisombululo: 1. Lungisa amandla e-laser; 2. Lungisa ugxininiso lwelaser.

7. Ingxaki: ubukhulu be-weld abufani

Umthungo weWeld ngamanye amaxesha mkhulu kakhulu, ngamanye amaxesha umncinci kakhulu, okanye ngamanye amaxesha uqhelekile.

Unobangela wengxaki: ukukhanya okanye ucingo lokutya akuyongxaki.

Isisombululo: Jonga ukuzinza kwelaser kunye ne-wire feeder, kubandakanywa amandla ombane ombane, inkqubo yokupholisa, inkqubo yokulawula, ucingo lokumisa, njl.

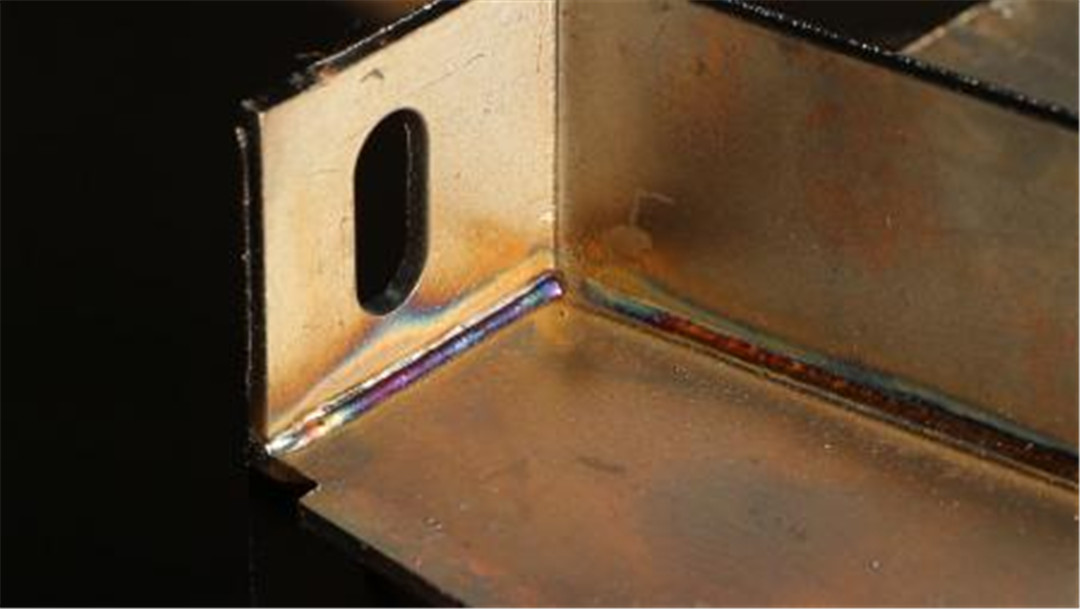

8. Ingxaki: Edge yokuluma

I-bite edge ibhekisela kwi-weld kunye nempahla ayidibanisi kakuhle, i-beveling kunye nezinye iimeko, ngaloo ndlela ichaphazela umgangatho we-welding.

Isizathu sengxaki: isantya se-welding sikhawuleza kakhulu, okubangelwa ukuba i-melt pool ayisasazwanga ngokulinganayo kumacala omabini ezinto eziphathekayo, okanye i-gap yezinto eziphathekayo zikhulu, izinto zokuzalisa akwanele.

Isisombululo: 1. Lungisa amandla e-laser kunye nesantya ngokwamandla ezinto eziphathekayo kunye nobukhulu be-weld seam; 2. Yenza umsebenzi wokugcwalisa okanye wokulungisa kamva.

IMaven Laser Automation Co.,Ltd. (I-Maven laser ngokufutshane) ngumvelisi ohamba phambili weenkqubo ze-laser kunye nezisombululo ezizenzekelayo ezizenzekelayo, eziseShenzhen, eChina, ezisekelwe kwi-2008. Iimveliso zethu zobuchwephesha zezi: umatshini wokucoca i-laser, umatshini we-laser welding, umatshini we-robot welding kunye nomatshini we-platform welding, ukuba unayo nayiphi na imibuzo yobungcali, wamkelekile ukuba uqhagamshelane nathi.

Ixesha lokuposa: Nov-18-2022