UkuLungisa umatshini wokuwelda weLaser ochanekileyo wokuMbumba

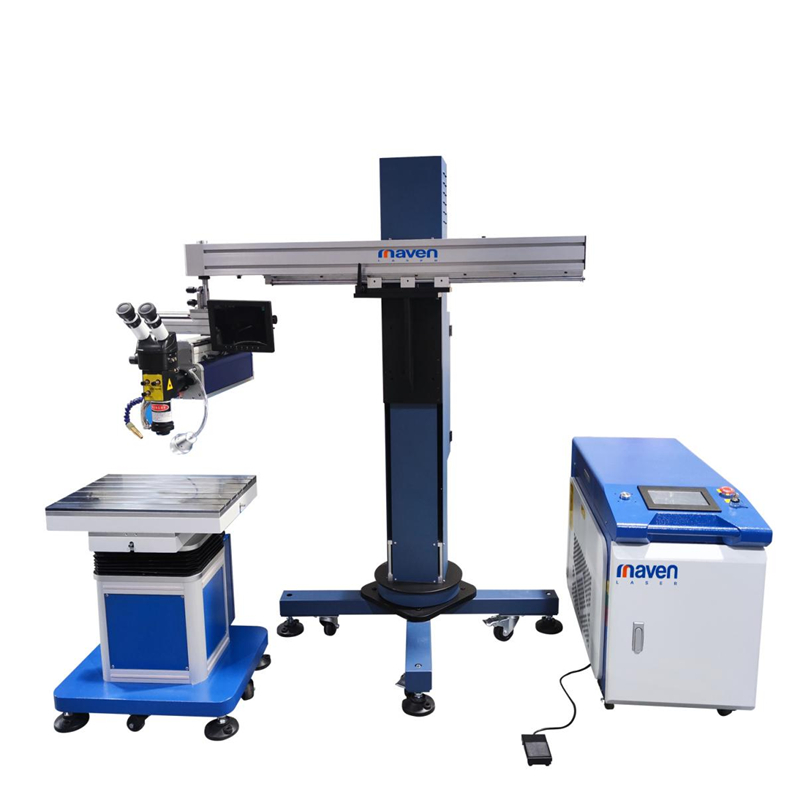

| Into | Igama leParameter | Idatha |

| Laser Source Parameter | MAX OKUPHUMA AMANDLA | 1000W/1500W/2000W |

| AMANDLA EWONKE | 4KW | |

| LASER WAVELENGTH | 1080nm | |

| MAXIMUM LASER PULSE AMANDLA | 70J/50ms | |

| UBUNZI BOMDLALO | 1-50ms | |

| UKUQHUBEKA KWE-PULSE | 1-100HZ | |

| Umsebenzi weWelding | ULUNGISELELO LWESPOT | 0.1-3.0mm |

| Ubukhulu bendawo | 0.2mm-3mm | |

| UBUKHULU BELENS | F150mm | |

| UKUSHIYA KWE-WElding | 0.1-1.2mm | |

| UKUJONGA INDAWO | Imicroscope (CCD nayo inokongezwa) | |

| Inkqubo yokulawula | LASER UMTHOMBO UPSIDE SUSA UBUDE | 300mm |

| UMTHOMBO WOKUSUKA INKCAZELO | 360D iDegree | |

| LASER ULAWULO LWE-HORIZONTAL | Y intshukumo | |

| 3D UMSEBENZI WOKUSEBENZA | XY manual,Z injini | |

| IiPropati zoMzimba kunye nezinye | AMANZI ENGAPHOLIYO | 1.2P |

| I-VOLTAGE YAMANDLA | 220V±10% 50Hz 30A | |

| IMEKO YOKUSEBENZA | Coca akukho mhlwa, 13℃-28℃ | |

| IYADLELWA | Isipili esikhuselweyo |

Iinzuzo zeMveliso

Umgaqo we-mold laser welding machine.

Umatshini wokuwelda usetyenziswa ikakhulu ukugcwalisa imingxunya kunye ne-trachoma ye-welding yegolide kunye nobucwebe besilivere. Stainless steel laser spot welder yinkalo ebalulekileyo ye-laser spot welder kwisicelo seteknoloji yokucubungula izinto ze-laser.

Omnye wemiba ebalulekileyo, inkqubo yokuwelda indawo ye-laser luhlobo lokuqhuba ubushushu, oko kukuthi, i-laser radiation yokufudumeza umphezulu we-workpiece, ubushushu obungaphezulu ngokuhambisa ubushushu ukuya kwi-diffusion yangaphakathi.

Inkqubo ye-laser ye-welding yodidi lobushushu, apho i-laser radiation ifudumeza umphezulu we-workpiece kunye nobushushu obuphezulu busasazeka ngaphakathi ngokuqhuba ubushushu. Ngenxa yeenzuzo zayo ezizodwa

Isetyenziswe ngempumelelo kwigolide kunye nesilivere yokulungisa ubucwebe kunye ne-welding ye-micro and small parts.

Iimpawu zomatshini we-mold laser welding.

◆ Yamkela i-Bhritane ephuma kwamanye amazwe i-ceramic spotting cavity, ukumelana nokugqwala, ukumelana nobushushu obuphezulu, ubomi bomgodi (8-10) iminyaka, ubomi besibane se-xenon ngaphezu kwamaxesha ezigidi ezisi-8.

◆ Yamkela inkqubo ye-shading ngokuzenzekelayo, ukuphelisa ukukhuthazwa kwamehlo ngexesha leeyure zokusebenza.

◆10X microscope magnification, inkomba yekhesa enqamlezileyo, kunye ne-automatic shading nge-high-speed LCD ivalve yokukhanya. Imveliso yegesi ekhuselayo ehambelana ne-laser iqinisekisa ukuba i-solder joint ihle kwaye i-solder joint ayiyi kuxutywa kwaye iguqulwe.

◆ Umboniso wamkela isikrini se-LED se-7-intshi, esinokuqonda ukutshintsha kwamahhala phakathi kweTshayina kunye nesiNgesi, kwaye ihambelana nemarike yamazwe ngamazwe.

Umatshini we-laser mold welding usetyenziswa ngokubanzi kwi-mold, i-injection echanekileyo yokubumba, i-die-casting, i-stamping, i-stainless steel kunye nezinye izinto ezinzima ezifana nokuqhekeka, ukutshiza, ukugaya kunye nokunxiba ukutywina ukulungiswa komphetho, ukuwelda, iibhetri zeselfowuni, ubucwebe, izixhobo ze-elektroniki, izixhobo zoluvo, oomatshini abachanekileyo, unxibelelwano, iiketile, iimbiza zewayini, iimbiza zekofu, ubugcisa kunye namanye amashishini.

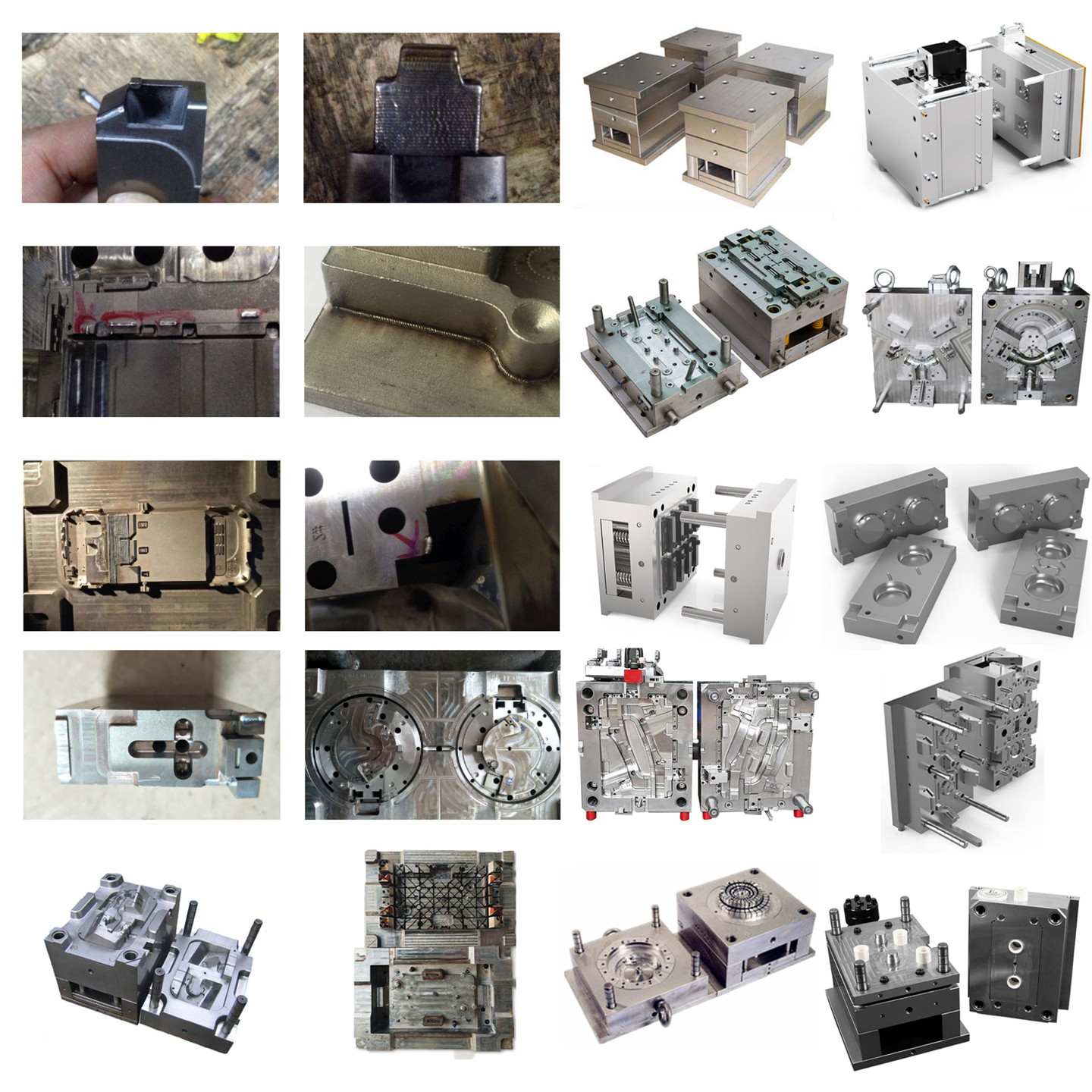

Isampulu kunye neSicelo