Yag Spot Jewelry Laser Welding Machine

Yag Laser Jewelry Laser Welding Machine

IIMBONAKALO

-Igolide kunye nesilivere yokulungisa i-welding ngaphandle kokupeyinta

-Ubuninzi 230W,90Joule

-50% yokonga amandla

-Umbono ophezulu weCCD,7intshi

-Iiyure ezingama-24 ukusebenza ngokuxabana

Ukhuseleko olulungileyo: nge-high-speed electronic light filter protection device ukukhusela amehlo omqhubi kumonakalo we-laser, ukukhulula ukukhathala kwamehlo omqhubi kunye nokuphucula ukusebenza kakuhle.

Ubuchule obunamandla bokuchasana nokuphazamiseka: Ukusetyenziswa kobuchwepheshe obutsha obuphambili bekhompyuter yolawulo lweshishini, endaweni yokusebenza ngokupheleleyo kweekhompyuter eziqhelekileyo, ukusebenza kwayo kunye nokuzinza kwinqanaba eliphezulu, kunye nokuhambelana namaxesha.

Ukuzinza okuphezulu: Ukusetyenziswa kwe-double-closed-loop precision precision control, ukuqinisekisa ukuba amandla kwindawo nganye ye-welding ifana kwaye ihambelana.

Ukusebenza okulula kunye nokufanelekileyo: kunye nombono omkhulu we-CCD weskrini esiphezulu, i-English interface parameter setting ilula ukuyiqonda, inokugcina iiparitha ezininzi ukuququzelela umsebenzi oqhubekayo.

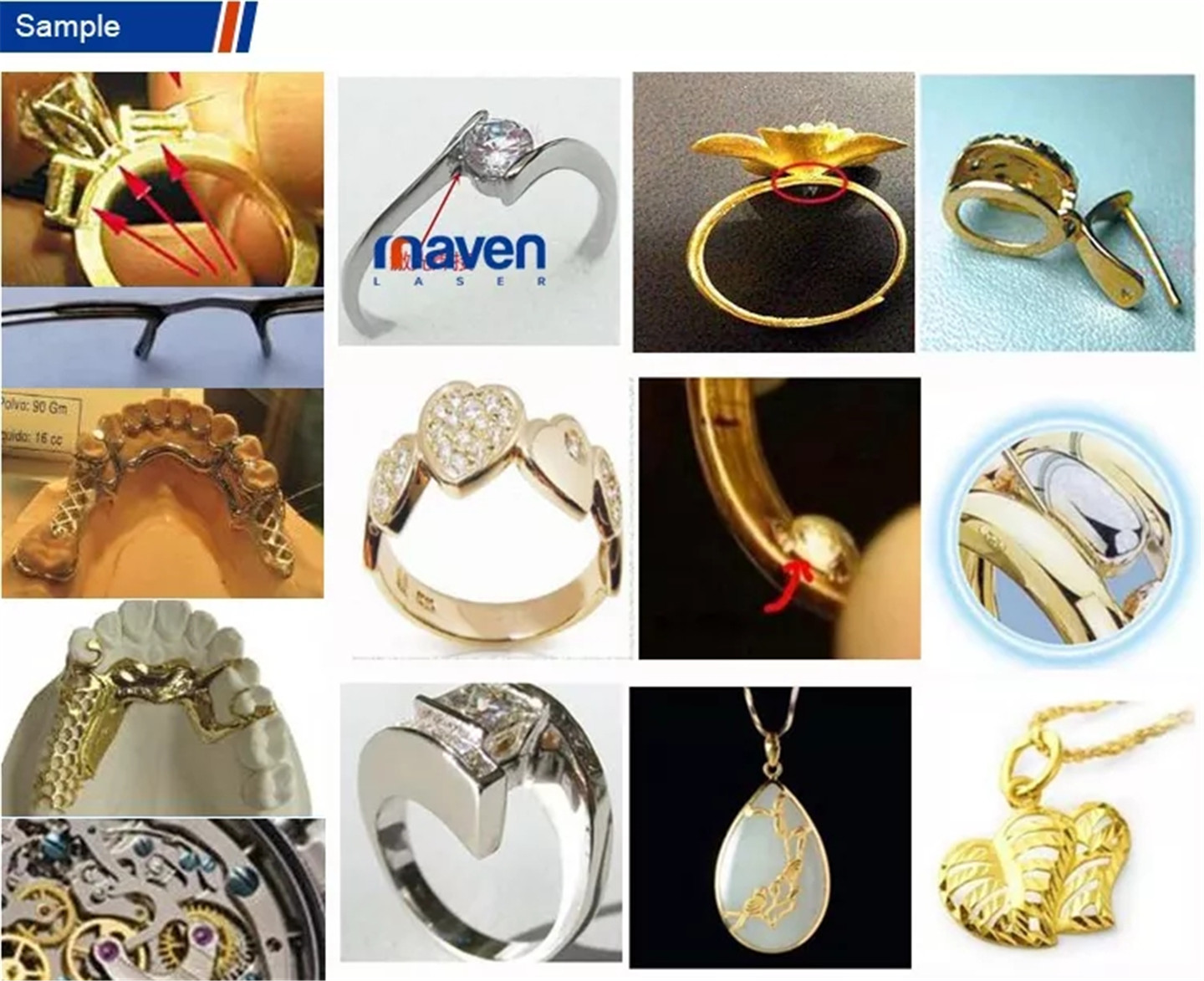

Laser indawo welderisetyenziswa ikakhulu kwizacholo nakwishishini lamazinyo okanye enye indawo yehardware. Olu hloboUmatshini unokuqhuba zonke izinto zetsimbi, ezazisetyenziselwa ukwenza ubucwebe njengegolide,isilivere, iplatinam, i-titanium, i-palladium, i-K-Gold, i-Stainless steel, kunye ne-alloys zabo. Isetyenziselwa ubukhulu becalaukuvelisa kunye nokulungiswa kwezacholo, kunye nokuwelda ngokuchanekileyo iindidi ezincinci kunye nobushushu-iindawo ezibuthathaka, njengemitya yenickel yeebhetri, iinwele, izinto zokubukela, iintambo eziphantsiiitshiphusi.

Iinzuzo zeMveliso

I-CCD iyonkejewelry laser welding machine

1. Gxininisa umnqamlezo wohlengahlengiso inxalenye

2. Ugxininiso lwendawo yokulungelelanisa

3. Iiparamitha ze-laser welding kwangaphambili. Kubandakanya igolide, isilivere, intsimbi, i-titanium kunye nesiko.

4. Ibha yereferensi yesimo

5. Amandla, ububanzi be-pulse kunye nokuphindaphinda ukulungelelanisa inxalenye

6. Ukusetha

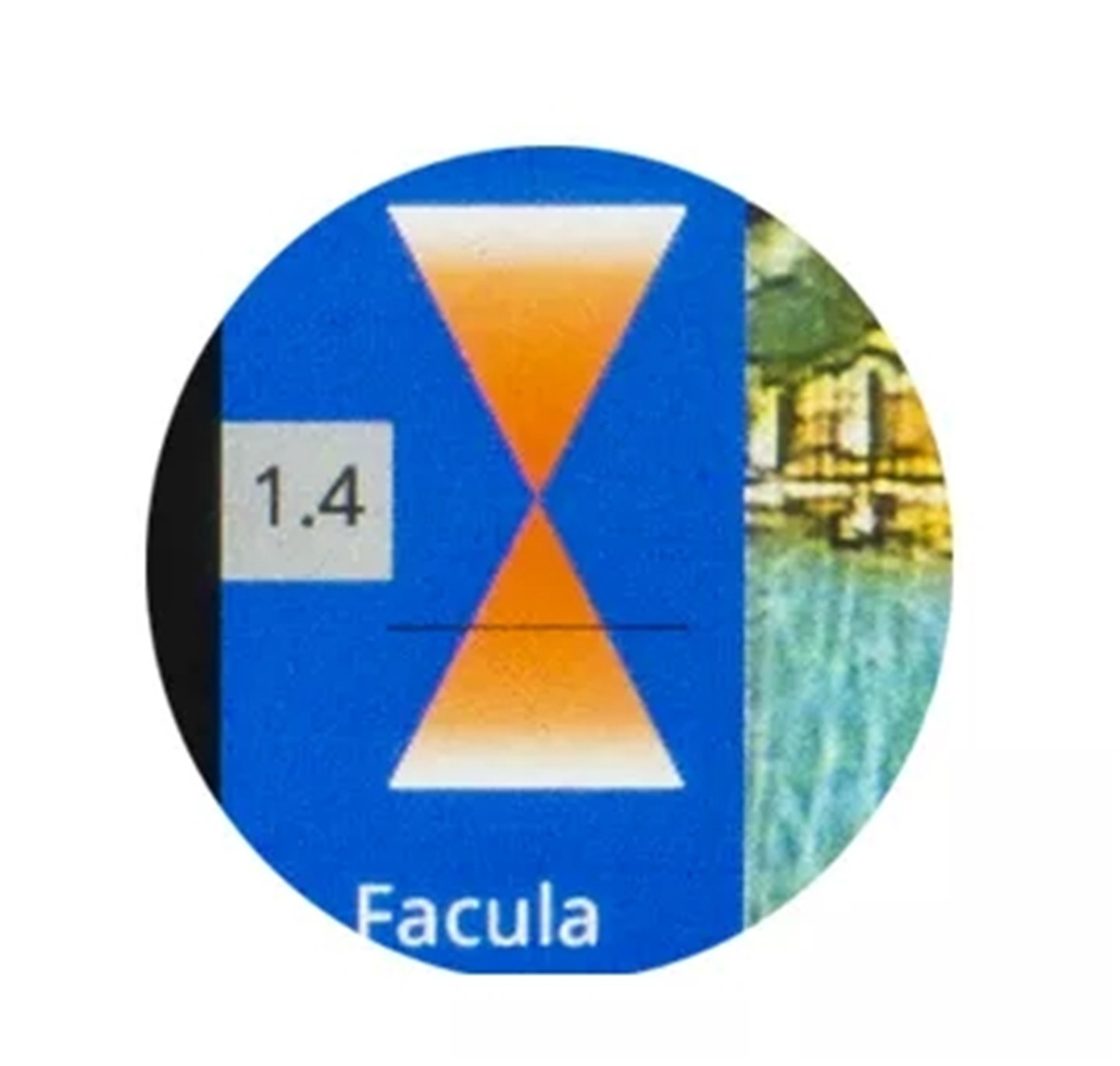

Ukulungiswa kobungakanani bendawo

Iisetingi zokulungelelaniswa komsebenzisi, ukusuka kwi--3.0mm ukuya kwi-3mm.

Ubungakanani bendawo kwiminus direction, ifaneleke ngakumbi ukulinganisa i-welding ye-post unyango kunye negolide encinci kunye ne-sheet yesilivere yokulungisa i-laser.

Ngelixa ukwicala elidityanisiweyo, kufanelekile ngakumbi kwi-laser spot welding

Gxininisa umgca onqamlezileyo wokulungisa iziko

Isikhundla sokugxila kumgca wesiphambano sinokuhlengahlengiswa ngokulula ngeli candelo

Seta kwangaphambili ipharamitha kunye nohlengahlengiso

I-Perst laser welding parameter yingcebiso yethu enye, kubandakanya i-K-Gold/Pt/Ti, isilivere, intsimbi, ubhedu kunye nesiko.

Amandla eLaser: 0.1%~100%

Pulse ububanzi: 0.1ms ~ 20ms

Ukuphindaphinda: 1Hz~50Hz

umendo wepatent

Indlela ye-patent ye-patent kunye noyilo lonke loyilo lomatshini wenza iMavenlaser yenkampanijewellery laser welding machineebalaseleyo kwaye igqibelele, hayi ekusebenzeni okanye kubungakanani.

Laser welding igumbi

1. Umbhobho womoya

2. Iqhosha likaxakeka

3. Ikhaphukhaphu ekumgangatho ophezulu emthubi

4. Umgangatho ophezulu we-White lighter

5. Spot manual echanekileyo ivili motor

6. Uvuyo

| Into | Amandla (%) | Ububanzi bokubetha (ms) | Ukuphindaphinda(Hz) | Ukupeyinta |

| Intsimbi | 17.5% | 1.0ms | 5Hz | Akukho mfuneko |

| I-K-Gold/Pt/Ti | 35.2% | 1.5ms | 5Hz | Akukho mfuneko |

| Ubhedu | 41.1% | 2.0ms | 4Hz | Akukho mfuneko |

| Isilivere | 60% | 1.0ms | 2.9Hz | Akukho mfuneko |

| Isiko | / | / | / | / |

Inkcazo

| Igama lemveliso | Jewelry laser welding machine |

| Umthombo weLaser | Nd: YAG 1064nm |

| Umzekelo No. | MLA-W-A01 |

| Amandla amakhulu e-laser | 230W |

| Uluhlu lokuphindaphinda | 1-50Hz |

| Uluhlu lobubanzi be-Pulse | 1 ~ 20ms |

| Uluhlu lobungakanani bendawo | -3mm ~ 3mm |

| Impembelelo yamandla kunye nexesha | 140J @20ms |

| Indawo ejolise kuyo | I-CCD, i-10X yemakroskophu |

| Ukubeka ukuchaneka | +/-0.02mm |

| Igalelo lombane | 220V 50/60Hz 30A |

| Ubungakanani bomatshini | 790*390*1090mm |

Isampulu kunye neSicelo