Umatshini wokuWelding wePlatform weLaser oKhuselekileyo ovaliweyo

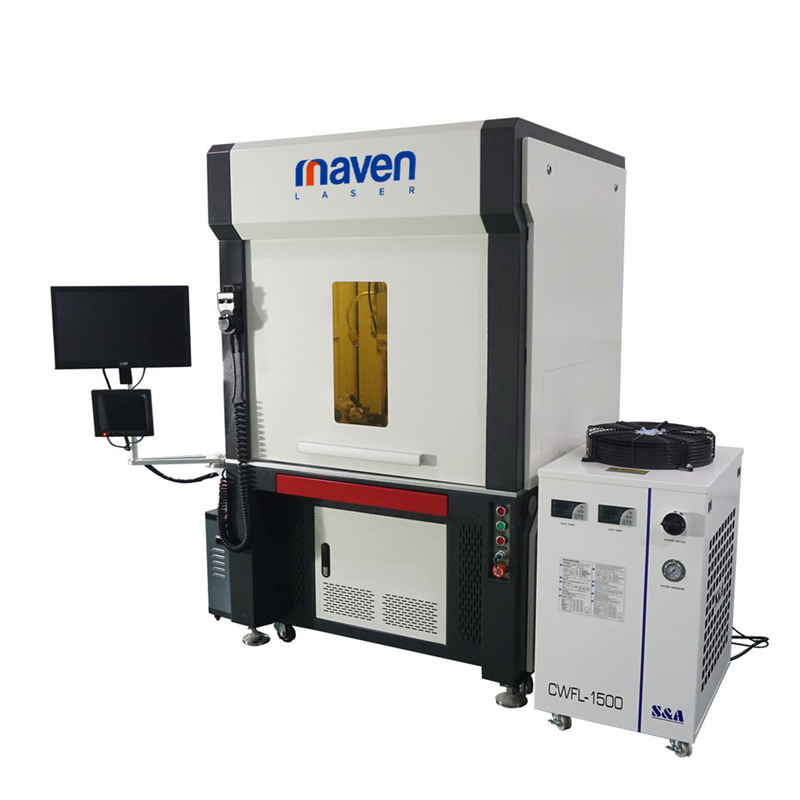

Ngokubanzi ibandakanya i-welding host kunye netafile ye-welding, i-laser beam edityaniswe nefayibha, emva kokudluliselwa komgama omde, iqhutywe ekugxininiseni ukukhanya okuhambelanayo kwi-workpiece yokuphumeza i-welding eqhubekayo, ngenxa yokuqhubekeka kokukhanya ukuze umphumo we-welding uqine, ulungile. kunye nomthungo omhle we-weld. Ngokwamashishini ahlukeneyo kunye neemfuno ezahlukeneyo, umatshini unokudityaniswa kunye nemilo kunye netafile ngokwendawo yemveliso ukufezekisa ukusebenza okuzenzekelayo, ukuhlangabezana ngokupheleleyo neemfuno zabathengi abahlukeneyo Ngaba i-butt weld, i-weld stack, itywina i-weld kwi-workpiece, isantya esikhawulezayo. , inokuhlangabezana ne-01mm-5mm ubukhulu be-welding ye-welding ye-welding Ukhuseleko lwegesi ephezulu, inokusebenza ixesha elide le-Laser beam energy adjustable, isantya sokunyakaza esilungelelanisiweyo, inokuba yintlobo ye-welding processing Laser welding i-automated kakhulu kwaye inokulawulwa ngekhompyutha, ngesantya esiphezulu se-welding kunye nokufikelela lula kuzo naziphi na iimilo ezinzima

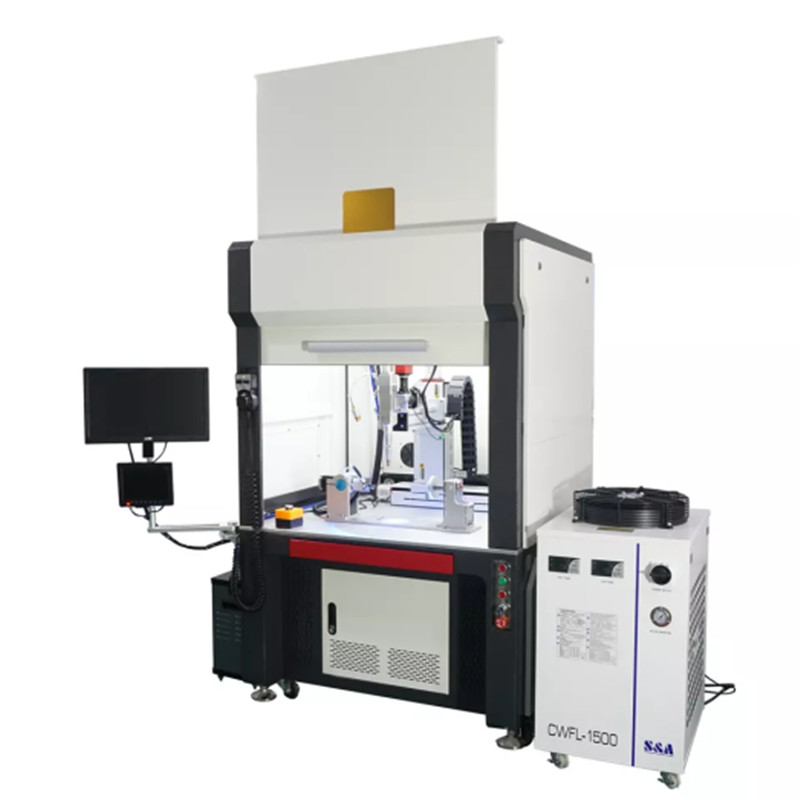

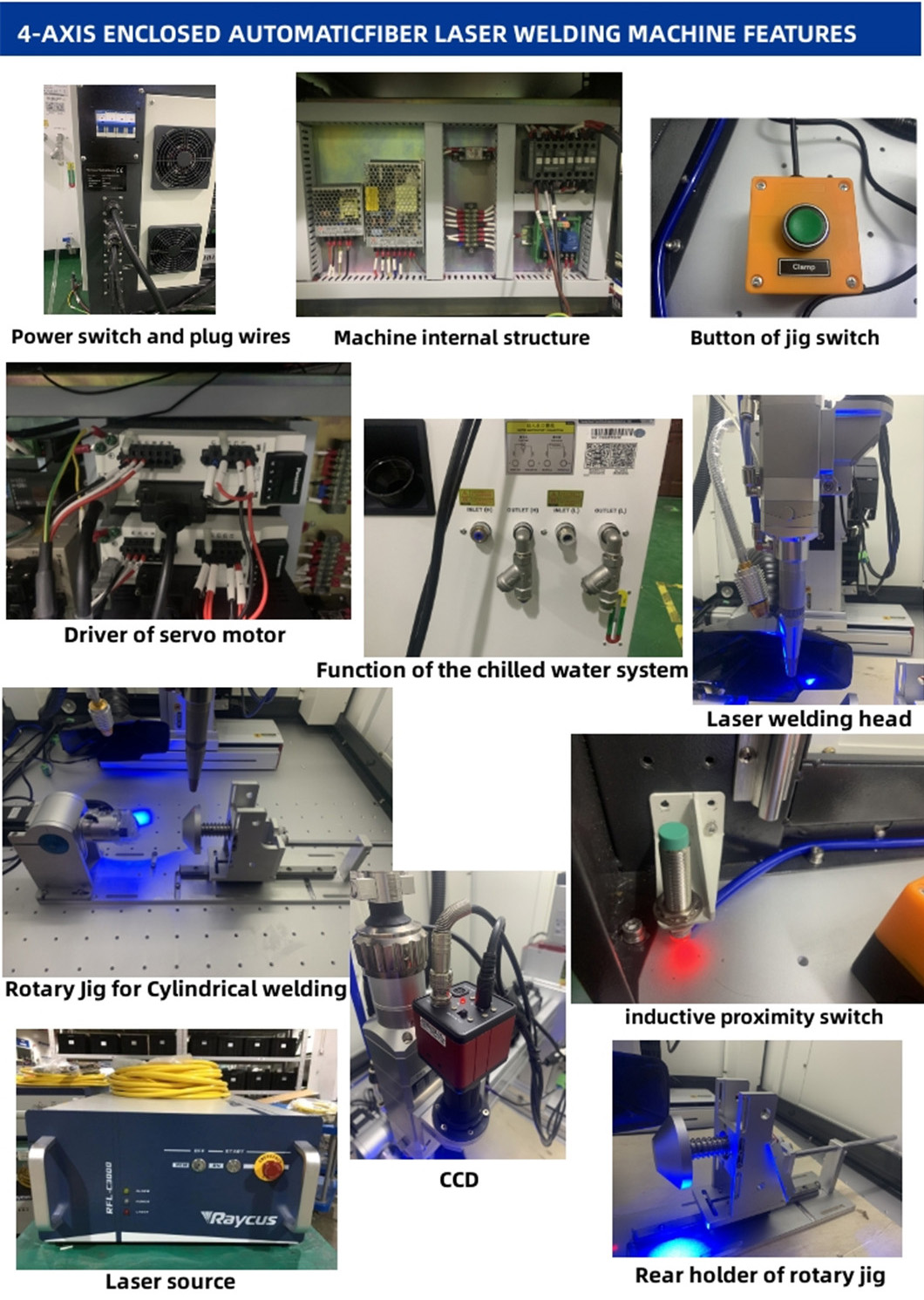

Amacandelo omatshini abonisa, i-4-AXIS yethu efakwe kwi-Automatic Fiber Laser Welding Machine ibandakanya ukutshintsha kwamandla kunye neengcingo zeplagi, iqhosha le-jig switch, i-diver ye-servo motor, umsebenzi wenkqubo yamanzi epholileyo, i-Rotary Jig ye-Cylindrical welding, umthombo weLaser, i-CCD Screen, ngasemva. umnikazi wejig ejikelezayo, i-inductive proximity switch kunye nentloko ye-laser welding

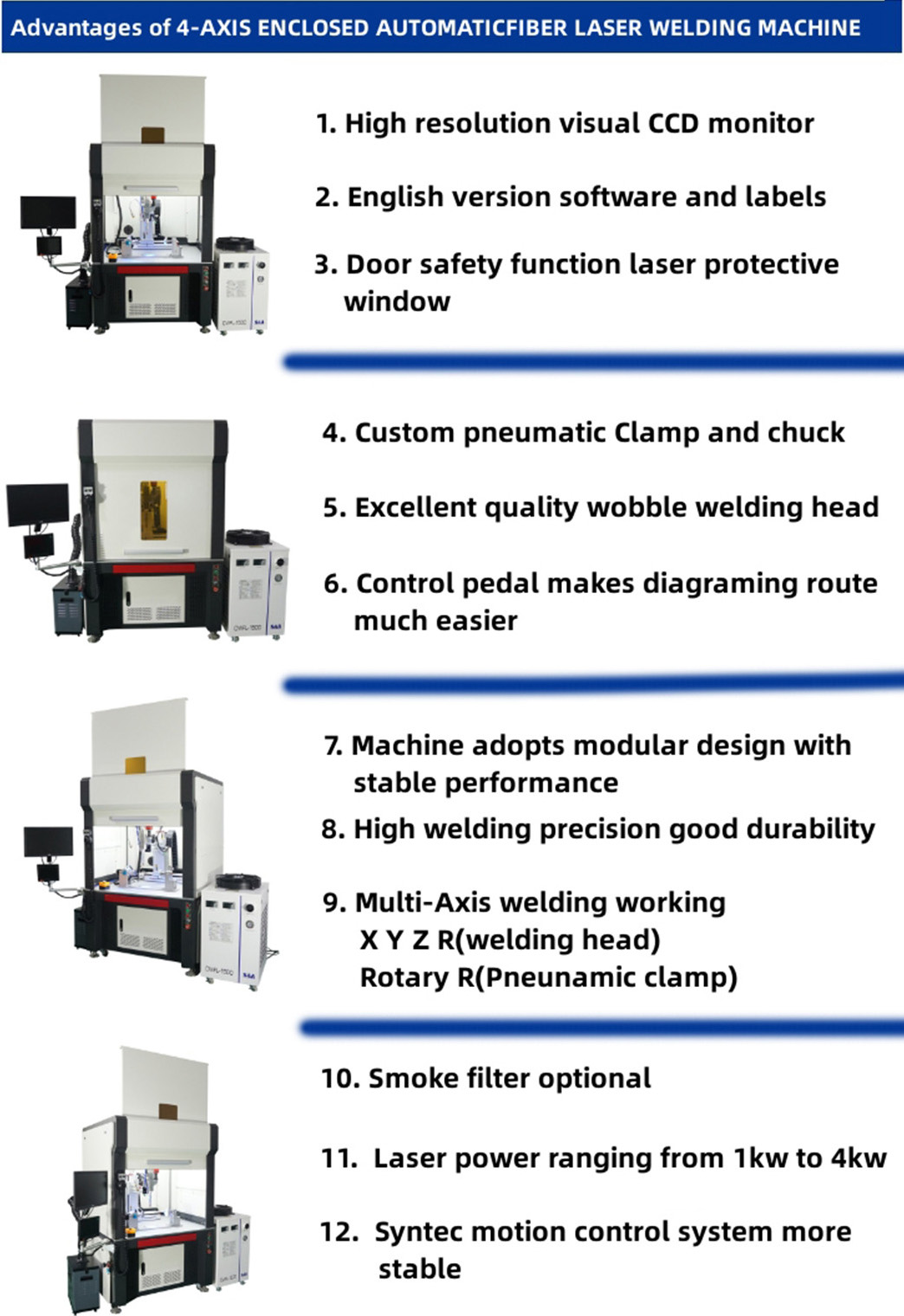

- Ukujongwa okuphezulu kweCCD ebonakalayo

- Isoftware yenguqulelo yesiNgesi kunye neelebhile

- Umsebenzi wokhuseleko emnyango wefestile ye-laser yokukhusela

- I-Clamp ye-pneumatic yesiko kunye ne-chuck

- Umgangatho ogqwesileyo welding welding intloko

- I-pedal yokulawula yenza indlela yokuzoba lula kakhulu

- Umatshini wamkela uyilo lwemodyuli kunye nokusebenza okuzinzileyo

- Ukuchaneka okuphezulu kwe-welding ukuqina okuhle

- I-Multi-Axis welding esebenzayo i-XYZR(intloko yokuwelda) iRotary R(i-Pneunamic clamp)

Isihluzo somsi sinokuzikhethela

Amandla eLaser ukusuka kwi-1KW ukuya kwi-4KW

Inkqubo yolawulo lwentshukumo yeSyntec izinzile ngakumbi

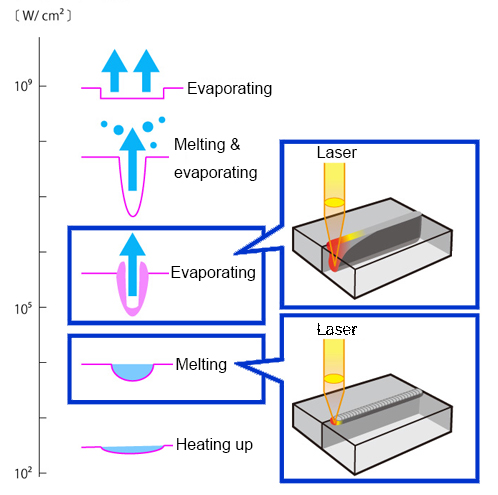

Umgaqo we-fiber laser welding

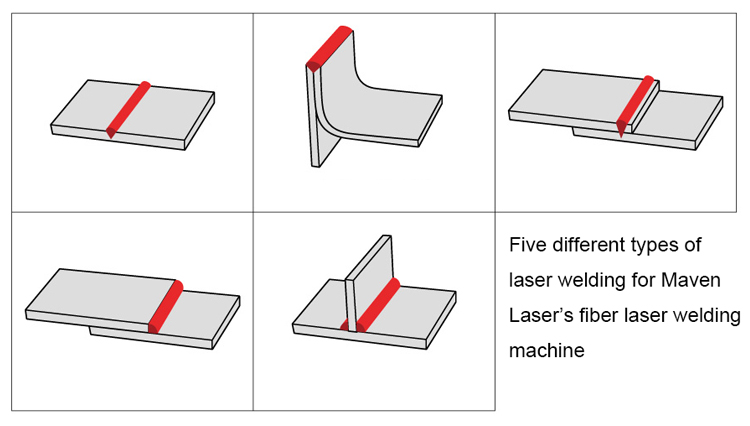

Ukuxinana okwahlukileyo kwe-laser beam kubangela iintlobo ezahlukeneyo ze-laser welding.

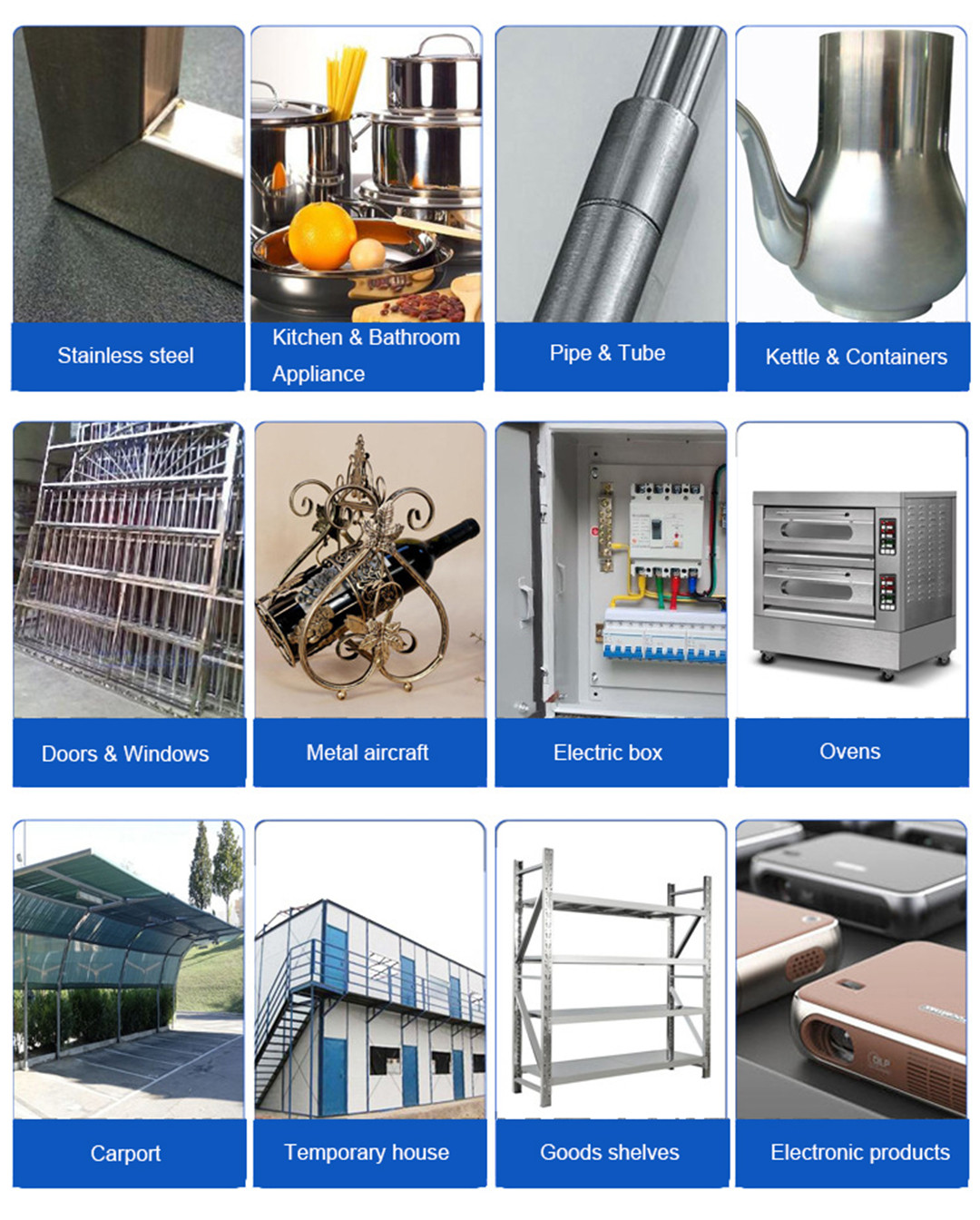

Material: Aluminiyam / intsimbi engatyiwayo / carbon

Ukubonakaliswa kunye nokuchuma kwayo kukhokelela kwiiparamitha ezahlukeneyo ze-laser welding.

Ububanzi besithuba: Ngokuqhelekileyo ububanzi besithuba kufuneka bube ngaphantsi kwe-0.5mm. I-wire feeder efunekayo xa ixabiso lisuka kwi-0.5mm ukuya kwi-1.0mm.

Ubunzulu obunyibilikayo: Ngokwesiqhelo ngaphantsi kwe-3.0mm, ukuwelda kwelaser enamacala amabini kuyacetyiswa xa kufikwa kwizinto ezityebileyo.

Isiqinisekiso sabasebenzi: Umsebenzisi onobuhlobo, kwaye kulula

ukusebenza.

Iimpawu kunye neentlobo ze-laser welding

I-Welding enemfuno ephezulu. Uxinzelelo lwamandla luphezulu kwaye isiphumo sobushushu sincinci ngokuyinxenye, ubunzima ngenxa yobushushu bunokugcinwa buphantsi.

Ukuhanjiswa ngokulula komthombo wefiber laser, enokunyusa imveliso

Ukungaqhagamshelwa, ukuwelda okubhetyebhetye kakhulu kunokwenzeka

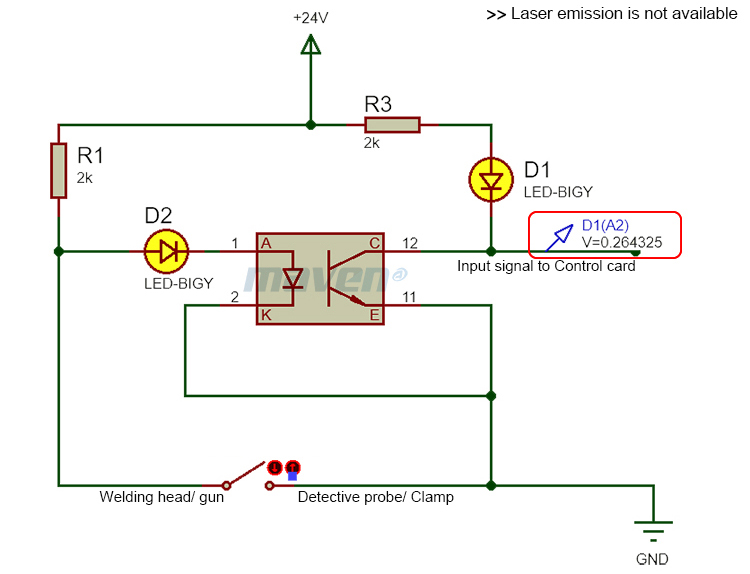

Ukukhutshwa kweLaser akufumaneki

1. Intloko ye-Welding ayidityaniswanga ne-detective probe, nokuba ngokuthe ngqo okanye hayi.

2. Isiginali yegalelo leVDC yiDC0V.

Ukudubula kweLaser akufumaneki

I-automatic laser welding system inemithetho efanayo yokukhusela ukusetyenziswa kwelaser

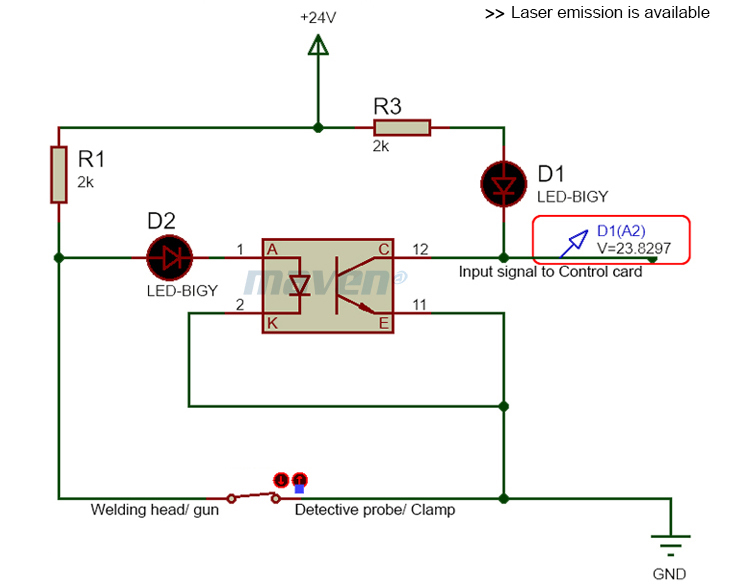

Ukufumaneka kokukhutshwa kweLaser

Ubume

1. Intloko ye-welding idibaniswe ne-detective probe, nokuba ngokuthe ngqo okanye hayi.

2. Isiginali yegalelo leVDC yiDC24V.

Isiphumo

Ukudubula kweLaser kuyafumaneka ngoku

NONE

I-automatic laser welding system inemithetho efanayo yokukhusela ukusetyenziswa kwelaser

| Ukusetyenziswa | I-Industry Welding |

| Imilinganiselo | 1200*1130*1650 mm |

| Laser Source Brand | Max, JPT, Raycus |

| I-Servo Motor Brand | Panasonic |

| Amashishini asebenzayo | Iihotele, iVenkile yeMpahla, iiVenkile zezinto zokwakha |

| Imo yeWelding | CW/Pulse |

| Imfuneko ye-welding gap | < 1mm |

| Igalelo lamandla | I-AC 380V |

| I-4-Axis | I-XYZR(intloko yokuwelda) R(I-Pneunamic clamp) |

| Max. Amandla emveliso | 4000W |

| Ubude bamaza | 1064 nm |

| Uphawu lwenkqubo yokulawula | Syntec okanye ukuziphuhlisa |

| Iwaranti | 1.5 iminyaka |

| Uluhlu lohlengahlengiso lwamandla | 10%-100% |

| Ubukhulu be-weld | 0.2-6 mm |

| Ukuphola | Ukuphola kwamanzi |

| Amandla omatshini | ≤5000W |

| Ubude beFayibha | 10 m okanye ichaziwe |

| Izinto eziphathekayo | Igesi ekhuselayo | Ukutyeba(mm) | 500W | 1000W | 1500W |

| Aluminiyam | N2/Ar | 1 | √ | √ | |

| 1.2 | √ | √ | |||

| 1.5 | √ | √ | |||

| 2 | √ | √ | |||

| 2.5 | √ | ||||

| Yenziwe ngentsimbi eshayinayo | N2/Ar | 0.5 | √ | √ | √ |

| 0.8 | √ | √ | √ | ||

| 1 | √ | √ | √ | ||

| 1.2 | √ | √ | √ | ||

| 1.5 | √ | √ | √ | ||

| 2 | √ | √ | |||

| 2.5 | √ | √ | |||

| 3 | √ | ||||

| Intsimbi yeCarbon | N2/Ar | 0.5 | √ | √ | √ |

| 0.8 | √ | √ | √ | ||

| 1 | √ | √ | √ | ||

| 1.2 | √ | √ | √ | ||

| 1.5 | √ | √ | √ | ||

| 2 | √ | √ | |||

| 2.5 | √ | √ | |||

| 3 | √ | ||||

| Iphepha eliGalvanized | N2/Ar | 0.5 | √ | √ | √ |

| 0.8 | √ | √ | √ | ||

| 1 | √ | √ | √ | ||

| 1.2 | √ | √ | √ | ||

| 1.5 | √ | √ | |||

| 2 | √ | √ | |||

| 2.5 | √ |